Abstract

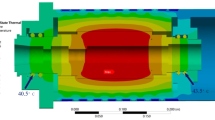

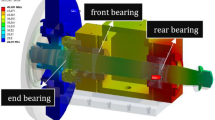

In order to improve the accuracy of the thermal error model of the electric spindle, a thermal error modeling method based on the optimized Elman neural network using the cuckoo algorithm is proposed. To analyze the thermal behavior of the electric spindle, an ANSYS analysis approach is utilized to create a temperature map. Based on the simulation analysis outcomes, an experimental platform is established to gather temperature data and thermal displacement data. The electric spindle temperature is optimized through the utilization of fuzzy cluster analysis and the Spearman rank correlation coefficient method in combination. The comparison between the established model and the Elman model and the GA-Elman model proves that the CS-Elman model has good prediction accuracy and stability.

Similar content being viewed by others

Data availability

All the data are required by experimental measurement in the article. On the basis of experimental theory, the calculation results of data are obtained.

References

Dai Y, Yin X, Wei W, Wang G, Zhan S (2020) Thermal error modeling of high speed motorized spindle based on ANFIS. Chin J Sci Instrum 41:50–58. https://doi.org/10.19650/j.cnki.cjsi.J2006202

Abdulshahed AM, Longstaff AP, Fletcher S, Myers A (2015) Thermal error modelling of machine tools based on ANFIS with fuzzy c-means clustering using a thermal imaging camera. Appl Math Model 39:1837–1852. https://doi.org/10.1016/j.apm.2014.10.016

Liu H, Miao E, Zhuang X, Wei X (2018) Thermal error robust modeling method for CNC machine tools based on a split unbiased estimation algorithm. Precis Eng 51:169–175. https://doi.org/10.1016/j.precisioneng.2017.08.007

Hucheng Z, Xuebing W, Chong W, Chaojie M, Reports (2022) Thermal Error Analysis of Machine Tool Spindle Based on BP Neural Network, 28:50–62. https://doi.org/10.9734/jsrr/2022/v28i111702

Liu J, Ma C, Gui H, Wang S (2022) Transfer learning-based thermal error prediction and control with deep residual LSTM network. 237:107704. https://doi.org/10.1016/j.knosys.2021.107704

Ni J (1997) CNC machine accuracy enhancement through real-time error compensation. 119:717–725. https://doi.org/10.1115/1.2836815

Zhou E, Zhao Y, Dai Y, Zhang J, Zhang Y, Li H (2021) Research on Temperature Field Prediction Model of Electric Spindle Based on Improved BP Neural Network. https://doi.org/10.21203/rs.3.rs-803914/v1

Liu J, Cai Y, Zhang Q, Zhang H, He H, Gao X, Ding L (2021) Thermal error analysis of tauren EDM machine tool based on FCM fuzzy clustering and RBF neural network. J Intell Fuzzy Syst 41:6003–6014. https://doi.org/10.3233/JIFS-202241

dos Santos MO, Batalha GF, Bordinassi EC, Miori GF (2018) Numerical and experimental modeling of thermal errors in a five-axis CNC machining center. Int J Adv Manuf Technol 96:2619–2642. https://doi.org/10.1007/s00170-018-1595-8

Fan L, Jing X, Chen J, Zhang K, Li D, Shi H, Ieee (2018) Research on thermal deformation modeling of high speed motorized spindle based on PLS. In 2018 Chinese Control And Decision Conference (CCDC), Sheng, China, pp 4247–4252. https://doi.org/10.1109/CCDC.2018.8407862

Chengyang W, Sitong X, Wansheng X (2021) Spindle thermal error prediction approach based on thermal infrared images: a deep learning method. 59:67–80. https://doi.org/10.1016/j.jmsy.2021.01.013

Caliński T, Harabasz J, Methods (1974) A dense method for cluster analysis. Commun Stat 3:1–27

Milligan GW, Cooper MCJP (1985) An examination of procedures for determining the number of clusters in a data set. 50:159-179. https://doi.org/10.1007/BF02294245

Gao X (2004) Fuzzy clustering analysis and its application. Xian University Publishing House, Xianan

Yang X-S, Deb SJC, O. Research (2013) Multiobjective cuckoo search for design optimization. 40:1616-1624. https://doi.org/10.1016/j.cor.2011.09.026

Zhou J, Zhu Z, Liu Y, Peng H, Gao Q (2011) Prediction of calorific value and ignition temperature of power coal blending based on Elman neural network. J Cent South Univ (Natural Science Edition) 42:3871–3875

Jinwen WU Wang Y. Zhou H, NTJMT University, Hydraulics (2019) Research on Thermal Error Compensation of Machine Tool Spindle Based on Simulated Annealing Coupled Particle Swarm Optimization and BP Neural Network. https://doi.org/10.3969/j.issn.1001-3881.2019.11.019

Zhang HN (2019) Research on modeling of machining center spindle thermal error based on improved RBF network. Tech Autom Appl 38:60–74

Li Z, Wang B, Zhu B, Wang Q, Zhu W (2022) Thermal error modeling of electrical spindle based on optimized ELM with marine predator algorithm. Case Stud Therm Eng 38. https://doi.org/10.1016/j.csite.2022.102326

Huang Y, Zhang J, Li X, Tian L (2014) Thermal error modeling by integrating GA and BP algorithms for the high-speed spindle. Int J Adv Manuf Technol 71:1669–1675. https://doi.org/10.1007/s00170-014-5606-0

Funding

This research was funded by the National Natural Science Foundation of China, grant number 52075134, the Opening Project of the Key Laboratory of Advanced Manufacturing and Intelligent Technology (Ministry of Education), Harbin University of Science and Technology, grant number KFKT202105, the Joint Guidance Project of Natural Science Foundation of Heilongjiang Province, grant number LH2019E062, and the Special Funding for Postdoctoral Fellows in Heilongjiang Province, grant number LBH-Q20097.

Author information

Authors and Affiliations

Contributions

The research work of this paper is the result of the joint efforts of the whole team. Ye Dai provided the research direction and experimental ideas. Xin Wang completed the experimental design and model simulation and wrote a paper. Gang Wang and Sai He assisted in the experimental verification. Xingwen Zhou assisted in the experimental simulation. Zhaolong Li checked the content and language of the paper. Baolei Yu reviewed the paper.

Corresponding author

Ethics declarations

Declarations

All authors have read and approved to submit it to your journal. This paper is the author’s original work. There is no conflict of interest of any authors in relation to the submission. This paper has not been published in advance, nor is it considered to be published elsewhere.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dai, Y., Wang, X., Li, Z. et al. Thermal error modeling of electric spindles based on cuckoo algorithm optimized Elman network. Int J Adv Manuf Technol 132, 1365–1375 (2024). https://doi.org/10.1007/s00170-024-13327-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13327-y