Abstract

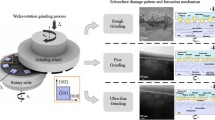

Gallium oxide is a semiconductor material with notable optoelectronic properties and thermal stability, with potential applications in optoelectronics, aerospace, and new energy sources, among others. Nevertheless, due to its high hardness and brittleness, gallium oxide poses challenges in efficient processing. The conventional grinding of gallium oxide often results in compromised surface quality accompanied by cracks and defects. In this study, we compared the outcomes of conventional grinding (CG) and axial ultrasonic-assisted grinding (AUVAG) on the (100) and (010) planes of single-crystal β-Ga2O3 material to investigate the grinding performance of the β-Ga2O3 surface. With the inclusion of axial ultrasound, the grinding force, grinding force ratio, and surface roughness of the (100) plane decreased by 12.39%, 8.71%, and 21.14%, respectively. The (010) plane showed reductions of 25.36%, 18.65%, and 15.68%, respectively. Moreover, we explored the influence of process parameters, including wheel grinding speed, feed rate, grinding depth, and ultrasonic amplitude, on the grinding force and surface roughness through orthogonal tests. The optimal process combination was identified under the current test parameters. The findings revealed that the grinding force, grinding force ratio, and surface roughness of different crystalline planes of β-Ga2O3 were reduced to varied extents, enhancing surface quality in comparison to conventional grinding. Notably, the (010) plane of β-Ga2O3 demonstrated superior grinding performance compared to the (100) plane. The insights from this study offer valuable guidance for refining the grinding techniques and processes of single-crystal β-Ga2O3 material.

Similar content being viewed by others

Availability of data and Material

The data that support the findings of this study are available from the corresponding author upon reasonable request.

Code availability

Not applicable.

References

Dikandé AM, Aban EC, Sunda-Meya A (2021) Thermal lensing-induced soliton molecules in β-phase gallium oxide. Microw Opt Technol Lett 63(12):3100–3107

Mu W, Jia Z, Yin Y (2017) High quality crystal growth and anisotropic physical characterization of β-Ga2O3 single crystals grown by EFG method. J Alloy Compd 714:453–458

Zhang H, Tang H-L, He N-T (2020) Growth and physical characterization of high resistivity Fe: β-Ga2O3 crystals. Chin Phys B 29(08):492–495

Gorai P, McKinney RW, Haegel NM (2019) A computational survey of semiconductors for power electronics. Energy Environ Sci 12(11):3338–3347

Kananen BE, Halliburton LE, Stevens KT (2017) Gallium vacancies in β-Ga2O3 crystals. Appl Phys Lett 110(20):202104

Hao J, Li L, Gao P (2023) Deep ultraviolet detectors based on wide bandgap semiconductors: a review. J Nanoparticle Res 25(4):81

Wang Y, Li X, Wu Y (2021) The removal mechanism and force modelling of gallium oxide single crystal in single grit grinding and nanoscratching. Int J Mech Sci 204:106562

Gao S, Wu Y, Kang R (2018) Nanogrinding induced surface and deformation mechanism of single crystal β-Ga2O3. Mater Sci Semicond Process 79:165–170

Yang Z, Sun W, He D (2021) Effect of laser-assisted ultrasonic vibration dressing parameters of a cubic boron nitride grinding wheel on grinding force, surface quality, and particle morphology. Rev Adv Mater Sci 60(1):691–701

Zhou H, Jiang W, Ji J (2021) Prediction and experimental investigation of depth of subsurface damage in semi-consolidated abrasive grinding of cleavable gallium oxide crystals. Int J Adv Manuf Technol 119(1–2):855–864

Zahedi A, Tawakoli T, Akbari J (2015) Energy aspects and workpiece surface characteristics in ultrasonic-assisted cylindrical grinding of alumina–zirconia ceramics. Int J Mach Tools Manuf 90:16–28

Zhao PY, Zhou M, Liu XL (2020) Effect to the surface composition in ultrasonic vibration-assisted grinding of BK7 optical glass. Appl Sci 10(2):516

Duan G, Shi B, Gu J (2021) Research of single-particle compression ratio and prediction of crushed products and wear on the 6-DOF robotic crusher. Math Probl Eng 2021:1–17

Qin S, Zhu L, Hao Y (2023) Theoretical and experimental investigations of surface generation induced by ultrasonic assisted grinding. Tribol Int 179:108120

Zhou M, Wang M, Dong G (2015) Experimental investigation on rotary ultrasonic face grinding of SiCp/Al composites. Mater Manuf Processes 31(5):673–678

Sun G, Shi F, Ma Z (2020) Effects of axial ultrasonic vibration on grinding quality in peripheral grinding and end grinding of ULE. Int J Adv Manuf Technol 109(7–8):2285–2298

Zhao J, Zhao B, Han M (2022) Grinding characteristics of ultra-high strength steel by ultrasonic vibration-assisted grinding with microcrystalline alumina wheel. Int J Adv Manuf Technol

Uhlmann E, Spur G (1998) Surface formation in creep feed grinding of advanced ceramics with and without ultrasonic assistance. CIRP Ann 47(1):249–252

Cao J, Wu Y, Lu D (2014) Material removal behavior in ultrasonic-assisted scratching of SiC ceramics with a single diamond tool. Int J Mach Tools Manuf 79:49–61

Li H, Lin B, Wan S (2015) An experimental investigation on ultrasonic vibration-assisted grinding of SiO2f/SiO2 composites. Mater Manuf Processes 31(7):887–895

Funding

National Natural Science Foundation of China (Nos. 51675457), Yancheng Institute of Technology Postgraduate Innovation Program Project (SJCX22_XZ013), Jiangsu Key Laboratory for Design and Manufacture of Micro/Nano Biomedical Instruments and School of Mechanical Engineering (Southeast University), Jiangsu Postgraduate Research and Innovation Program.

Author information

Authors and Affiliations

Contributions

Shixiang Hu: experimentation, data curation, and writing the original draft. Hai Zhou: supervision, conceptualization, and methodology. Youming Yang: data collection and manuscript revision. Xiangpu Ren: experimentation and methodology. Jinde Song: materials and technical support.

Corresponding author

Ethics declarations

Ethics approval

I would like to declare on behalf of my co-authors that the work described was original research that has not been published previously and is not under consideration for publication elsewhere, in whole or in part. All the authors listed have approved the manuscript that is enclosed.

Consent to participate

Written informed consent for publication was obtained from all participants.

Consent for publication

The authors agree to publication in the Int J Adv Manuf Technol in English.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hu, S., Zhou, H., Yang, Y. et al. Experimental investigation on axial ultrasonic-assisted grinding of different crystal surfaces of single-crystal gallium oxide. Int J Adv Manuf Technol 131, 4543–4556 (2024). https://doi.org/10.1007/s00170-024-13294-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13294-4