Abstract

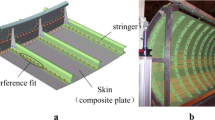

Geometric deviations and assembly deformations are inevitable in compliant assembly processes and have a significant impact on assembly quality. This paper proposes a variation propagation model based on isogeometric analysis (IGA), which unifies geometric deviations and compliant deformations in one framework by embedding exact geometry into assembly analysis. First, geometric deviations are modeled via offsets along control points using non-uniform rational basis spline (NURBS). Then, the elastic force induced by geometric deviation is calculated using Kirchhoff–Love shell elements. Further, clamping constraints, such as fixture positioning deviation and connection matching deviation, are transformed into displacement boundary conditions using the Lagrange multiplier method. Finally, several examples including the practical project cases are provided to demonstrate the accuracy and efficiency of the developed method in obtaining assembly deviation distributions.

Similar content being viewed by others

Data availability

Not applicable.

References

Camelio JA, Hu SJ, Marin SP (2004) Compliant assembly variation analysis using component geometric covariance. J Manuf Sci Eng 126:355–360. https://doi.org/10.1115/1.1644553

Franciosa P, Gerbino S, Patalano S (2011) Simulation of variational compliant assemblies with shape errors based on morphing mesh approach. Int J Adv Manuf Technol 53:47–61. https://doi.org/10.1007/s00170-010-2839-4

Sánchez-Reyes J, Chacón JM (2012) Hermite approximation for free-form deformation of curves and surfaces. Comput Aided Des 44:445–456. https://doi.org/10.1016/j.cad.2012.01.001

Zhang Z, Zhang Z, Jin X, Zhang Q (2018) A novel modelling method of geometric errors for precision assembly. Int J Adv Manuf Technol 94:1139–1160. https://doi.org/10.1007/s00170-017-0936-3

Luo C, Franciosa P, Ceglarek D, Ni Z, Jia F (2018) A novel geometric tolerance modeling inspired by parametric space envelope. Ieee T Autom Sci Eng 15:1386–1398. https://doi.org/10.1109/tase.2018.2793920

Babu M, Franciosa P, Shekhar P, Ceglarek D (2023) Object shape error modelling and simulation during early design phase by morphing Gaussian random fields. Comput-Aided Des 158:103481. https://doi.org/10.1016/j.cad.2023.103481

Dantan JY, Ballu A, Mathieu L (2008) Geometrical product specifications — model for product life cycle. Comput Aided Des 40:493–501. https://doi.org/10.1016/j.cad.2008.01.004

Anwer N, Ballu A, Mathieu L (2013) The skin model, a comprehensive geometric model for engineering design. Cirp Ann - Manuf Technol 62:143–146. https://doi.org/10.1016/j.cirp.2013.03.078

Schleich B, Wartzack S (2015) Approaches for the assembly simulation of skin model shapes. Comput Aided Des 65:18–33. https://doi.org/10.1016/j.cad.2015.03.004

Huang W, Ceglarek D (2002) Mode-based decomposition of part form error by discrete-cosine-transform with implementation to assembly and stamping system with compliant parts. CIRP Ann - Manuf Technol 51:21–26. https://doi.org/10.1016/s0007-8506(07)61457-7

Huang W, Liu J, Chalivendra V, Ceglarek D, Kong Z, Zhou Y (2014) Statistical modal analysis for variation characterization and application in manufacturing quality control. Iie Trans 46:497–511. https://doi.org/10.1080/0740817x.2013.814928

Samper S, Formosa F (2007) Form defects tolerancing by natural modes analysis. J Comput Inf Sci Eng 7:44–51. https://doi.org/10.1115/1.2424247

Grandjean J, Ledoux Y, Samper S (2013) On the role of form defects in assemblies subject to local deformations and mechanical loads. Int J Adv Manuf Technol 65:1769–1778. https://doi.org/10.1007/s00170-012-4298-6

Homri L, Goka E, Levasseur G, Dantan JY (2017) Tolerance analysis — form defects modeling and simulation by modal decomposition and optimization. Comput Aided Des 91:46–59. https://doi.org/10.1016/j.cad.2017.04.007

Li Y, Zhao Y, Yu H, Lai X (2017) Compliant assembly variation analysis of sheet metal with shape errors based on primitive deformation patterns. Proc Inst Mech Eng Part C J Mech Eng Sci 232:2334–2351. https://doi.org/10.1177/0954406217720231

Cao YL, Li B, Ye XF, Guan JY, Yang JX (2015) Geometrical simulation of multiscale toleranced surface with consideration of the tolerancing principle. J Comput Inf Sci Eng 15:021006. https://doi.org/10.1115/1.4028962

Liu SC, Hu SJ (1997) Variation simulation for deformable sheet metal assemblies using finite element methods. J Manuf Sci Eng 119:368–374. https://doi.org/10.1115/1.2831115

Camelio J, Hu SJ, Ceglarek D (2003) Modeling variation propagation of multi-station assembly systems with compliant parts. J Mech Des 125:673–681. https://doi.org/10.1115/1.1631574

Zhang T, Shi J (2016) Stream of variation modeling and analysis for compliant composite part assembly— part II: multistation processes. J Manuf Sci Eng 138:121004. https://doi.org/10.1115/1.4033282

Zhang T, Shi J (2016) Stream of variation modeling and analysis for compliant composite part assembly—part I: single-station processes. J Manuf Sci Eng 138:121003. https://doi.org/10.1115/1.4033231

Choi W, Chung H (2018) Variation simulation model for pre-stress effect on welding distortion in multi-stage assemblies. Thin Wall Struct 127:832–843. https://doi.org/10.1016/j.tws.2018.03.018

Choi W, Chung H (2015) Variation simulation of compliant metal plate assemblies considering welding distortion. J Manuf Sci Eng 137:031008. https://doi.org/10.1115/1.4029755

Atik H, Chahbouni M, Amagouz D, Boutahari S (2018) An analysis of springback of compliant assemblies by contact modeling and welding distortion. Int J Eng Technol 7:85–89. https://doi.org/10.14419/ijet.v7i1.8330

Abdelal GF, Georgiou G, Cooper J, Robotham A, Levers A, Lunt P (2015) Numerical and experimental investigation of aircraft panel deformations during riveting process. J Manuf Sci Eng 137:011009. https://doi.org/10.1115/1.4028923

Liu T, Li Z, Jin S, Chen W (2018) Compliant assembly analysis including initial deviations and geometric nonlinearity, part II: plate structure. Proc Inst Mech Eng Part C J Mech Eng Sci 233:3717–3732. https://doi.org/10.1177/0954406218806930

Liu T, Li Z, Jin S, Chen W (2018) Compliant assembly analysis including initial deviations and geometric nonlinearity—Part I: beam structure. Proc Inst Mech Eng Part C J Mech Eng Sci 233:4233–4246. https://doi.org/10.1177/0954406218813392

Liu C, Liu T, Du J, Zhang Y, Lai X, Shi J (2020) Hybrid nonlinear variation modeling of compliant metal plate assemblies considering welding shrinkage and angular distortion. J Manuf Sci Eng 142:041003. https://doi.org/10.1115/1.4046250

Yu H, Zhao C, Lai X (2018) Compliant assembly variation analysis of scalloped segment plates with a new irregular quadrilateral plate element via ANCF. J Manuf Sci Eng 140:091006. https://doi.org/10.1115/1.4040323

Yu H, Zhao C, Zheng B, Wang H (2018) Compliant assembly variation analysis of thin-walled structures based on the absolute nodal coordinate formulation. Assem Autom 38:125–141. https://doi.org/10.1108/aa-05-2016-046

Hughes TJR, Cottrell JA, Bazilevs Y (2005) Isogeometric analysis: CAD, finite elements, NURBS, exact geometry and mesh refinement. Comput Method Appl M 194:4135–4195. https://doi.org/10.1016/j.cma.2004.10.008

Huynh GD, Zhuang X, Bui HG, Meschke G, Nguyen-Xuan H (2020) Elasto-plastic large deformation analysis of multi-patch thin shells by isogeometric approach. Finite Elem Anal Des 173:103389. https://doi.org/10.1016/j.finel.2020.103389

Peng X, Xu G, Zhou A, Yang Y, Ma Z (2020) An adaptive Bernstein-Bézier finite element method for heat transfer analysis in welding. Adv Eng Softw 148:102855. https://doi.org/10.1016/j.advengsoft.2020.102855

Modirkhazeni SM, Bhigamudre VG, Trelles JP (2020) Evaluation of a nonlinear variational multiscale method for fluid transport problems. Comput Fluids 209:104531. https://doi.org/10.1016/j.compfluid.2020.104531

Hosters N, Helmig J, Stavrev A, Behr M, Elgeti S (2018) Fluid–structure interaction with NURBS-based coupling. Comput Method Appl M 332:520–539. https://doi.org/10.1016/j.cma.2018.01.003

Rupal BS, Anwer N, Secanell M, Qureshi AJ (2020) Geometric tolerance and manufacturing assemblability estimation of metal additive manufacturing (AM) processes. Mater Des 194:108842. https://doi.org/10.1016/j.matdes.2020.108842

Piegl L, Tiller W (1997) The NURBS Book. Monogr Vis Commun. https://doi.org/10.1007/978-3-642-59223-2

Ludwig T, Hühne C, Lorenzis LD (2019) Rotation-free Bernstein-Bézier elements for thin plates and shells – development and validation. Comput Method Appl M 348:500–534. https://doi.org/10.1016/j.cma.2019.01.039

Zareh M, Qian X (2019) Kirchhoff-Love shell formulation based on triangular isogeometric analysis. Comput Method Appl M 347:853–873. https://doi.org/10.1016/j.cma.2018.12.034

Chen L, Nguyen-Thanh N, Nguyen-Xuan H, Rabczuk T, Bordas SPA, Limbert G (2014) Explicit finite deformation analysis of isogeometric membranes. Comput Method Appl M 277:104–130. https://doi.org/10.1016/j.cma.2014.04.015

Hirschler T, Bouclier R, Dureisseix D, Duval A, Elguedj T, Morlier J (2019) A dual domain decomposition algorithm for the analysis of non-conforming isogeometric Kirchhoff-Love shells. Comput Method Appl M 357:112578. https://doi.org/10.1016/j.cma.2019.112578

Schuß S, Dittmann M, Wohlmuth B, Klinkel S, Hesch C (2019) Multi-patch isogeometric analysis for Kirchhoff-Love shell elements. Comput Method Appl M 349:91–116. https://doi.org/10.1016/j.cma.2019.02.015

Liu N, Jeffers AE (2018) A geometrically exact isogeometric Kirchhoff plate: feature-preserving automatic meshing and C1 rational triangular Bézier spline discretizations. Int J Numer Meth Eng 115:395–409. https://doi.org/10.1002/nme.5809

Funding

The work described in this paper is supported in part by grants from the National Natural Science Foundation of China (award numbers: 51775346 and 52005334) and the Natural Science Foundation of Chongqing, China (Grant No. cstc2021jcyj-msxmX1104).

Author information

Authors and Affiliations

Contributions

Jinyu Liu: conceptualization; methodology; software; validation; visualization; writing—original draft; writing—review and editing.

Zhi-Min Li: conceptualization; methodology; validation; visualization; supervision; writing—review and editing.

Tao Liu: validation; visualization; supervision; writing—review and editing.

Yanzheng Zhao: validation; visualization; supervision; writing—review and editing.

Corresponding author

Ethics declarations

Ethics approval

Yes.

Consent to participate

Yes, the authors consent to participate.

Consent for publication

Yes, the authors consent to publish.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, J., Li, Z., Liu, T. et al. Compliant assembly variation modeling for thin-walled structures considering clamping constraints and geometric deviations based on isogeometric analysis. Int J Adv Manuf Technol 132, 127–146 (2024). https://doi.org/10.1007/s00170-024-13248-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13248-w