Abstract

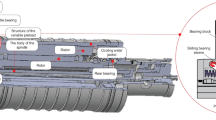

The precision of machine tools heavily relies on the motorized spindle’s performance. It is crucial to guarantee the thermal error prediction model’s improved accuracy, as it enables enhanced machining accuracy, reduced errors, and effective control over the prediction model. The northern goshawk optimization (NGO) algorithm is used to optimize the kernel extreme learning machine (KELM) to address thermal error issues. Based on the analysis conducted, the best four temperature measurement locations are chosen. The established thermal error prediction model, combining NGO and KELM, is compared with both the basic KELM model and BA-KELM through comprehensive analysis. The results show that the determination coefficient R2 of NGO-KELM model is 0.132 and 0.026 higher than KELM and BA-KELM. The robustness, stability, and generalization ability of the NGO-KELM modeling method are verified. In order to further reduce the thermal error, this paper puts forward a method of adding a microradiator to the contact between the front and rear bearing chambers and the bearings. The findings demonstrate that it is possible to efficiently lower the temperature at the front and rear bearings and suppress the thermal deformation of the motorized spindle.

Similar content being viewed by others

Data availability

The data that has been used is confidential.

References

Wang HT, Li TM, Wang LP et al (2015) Review on thermal error modeling of machine tools. J Mech Eng 51:119–128

Han Liu K, Wang W, Liu YQ et al (2021) Review on thermal error compensation for axes of CNC machine tools. J Mech Eng 57(156):173

Li Y, Yu ML, Bai YM, Hou ZY et al (2021) A review of thermal error modeling methods for machine tools. J Appl Sci 11(11):52163

Zhou CY, Zhuang LY, Yuan J et al (2018) K-means optimization and experiment of temperature measuring point of machine tool spindle. J Mech Des Manuf 05:41–43+47

Chen S, Wang YQ, Zhi Y et al (2018) Study on optimization of coupling temperature measuring point for spindle thermal elongation modeling. J. Manuf Technol Mach Tools 03:98–102

Guo SJ, Zhang XW, Zhang N et al (2023) Selection of thermal key points of machine tool spindle and prediction of thermal error of typical speed. J Jilin University 53(01):72–81

Zhang L, Chen GH, Zhao DZ et al (2020) Optimization method of temperature measuring point of machine tool spindle based on fuzzy clustering and grey theory. J Mach Tools Hydr 48(22):85–90

Chen YM, Chen PM, Wang Z et al (2022) Simulation analysis of thermal characteristics of KX-1 motorized spindle based on ANSYS. J Electromech Eng Technol 51(10):169–173

Wu CQ, Hua WJ, Zhou Q et al (2018) Thermal characteristics analysis of mechanical spindle. J Mach Tools Hydr 46(23):156–159

Dai Y, Yin XM, Wei WQ et al (2020) Research on thermal error modeling of high-speed motorized spindle based on ANFIS. J Chinese J Sci Inst 41(06):50–58

Xin ZP, Feng XY, Du FX et al (2019) Modeling and analysis of machine tool thermal error based on BP neural network. J Combined Mach Tool Auto Mach Tech 08:39–43

Gaoqiang LI (2021) ZHANG Yu and LI Ming: Study on thermal error modeling method for CNC machine tool based on GA-LSS-VM. J. Mach Tool Hydr 49(2):26–30

Cao L, Peng Y, Yin M et al (2022) Thermal error modeling of spindle in horizontal machining center based on MEA-BP algorithm. J Combined Mach Tool Auto Mach Technol 07:30–3337

Sun A, Wang LS, Xie XL (2022) Thermal error modeling of spindle based on MEA-NARX neural network. J Mach Tools Hydr 50(24):49–53

Wen MF, Zhong JL, Peng BY et al (2022) Optimization modeling of thermal error of motorized spindle based on WOA-SVR. J. Mach Tools Hydr 50(22):38–42

Du LQ, Hu J, Yu YW (2022) Thermal error modeling of machine tools based on chaotic evolution and CNN-GRU. J. Combined Mach Tool Auto Mach Technol 08:18–20+25

Liu JL, Ma C, Gui HQ, Wang S (2021) L: Thermally-induced error compensation of spindle system based on long short term memory neural networks. J Applied Soft Comput J 102:107094

Yang X, Shi X, Mu Y et al (2019) Thermal error compensation model for a motorized spindle with shaft core cooling based on exponential function. J Int J Adv Manuf Technol 103(4805):4813

Peng LQ, Yu HT, Chen C, He QX, Zhang H, Zhao FL, Qin MM, Feng YY, Feng W (2023) Tailoring dense, orientation-tunable, and interleavedly structured carbon-based heat dissipation plates. Adv. Sci 10:2205962

Lu LB, Zhang Z, Guan YC, Zheng HY (2018) Enhancement of heat dissipation by laser micro structuring for LED module. Polymers 10:886

You YX, Zhang BB, Tao SL, Liang ZH, Tang B, Zhou R, Yuan D (2021) Effect of surface microstructure on the heat dissipation performance of heat sinks used in electronic devices. Micromachines 12:265

Zhuang J, Hu W, Fan YQ, Sun JY, He XX, Xu H, Huang Y, Wu DM (2019) Fabrication and testing of metal/polymer microstructure heat exchangers based on micro embossed molding method. Microsyst Technol 25:381–388

Ventola L, Chiavazzo E, Calignano F, Manfredi D, Asinari P (2014) Heat transfer enhancement by finned heat sinks with micro-structured roughness. J Phys : Conf Series 494:012009

JJ Cheng, FX Wei, SY Chiam (2020) Electrodeposited copper micropillar surfaces with pulse reverse voltammetry for enhanced heat dissipation. ACS Appl Electron Mater 2(4):1041–1047

Dai Y, Yin XM, Wei WQ, Wang G, Zhan SQ (2020) Thermal error modeling of high-speed motorized spindle based on ANFIS. J Chinese J Sci Inst 41(6):50–58

Dehghani M, Hubalovsky S, Trojovsky P (2021) Northern goshawk optimization: a new swarm-based algorithm for solving optimization problems. M EEE Access 9:162059–162080

Funding

This work was supported by the Supported by Opening Project of the Key Laboratory of Advanced Manufacturing and Intelligent Technology (Ministry of Education) (grant number: KFKT202204) and National Natural Science Foundation of China (grant number: 52075134).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

The authors agree to participate.

Consent for publication

The authors agree with the publication.

Conflict of interest

The authors declare no competing interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhaolong, L., Benchao, S., Wenming, Z. et al. Thermal error modeling of motorized spindle and application of miniature radiator in motorized spindle. Int J Adv Manuf Technol 131, 1107–1118 (2024). https://doi.org/10.1007/s00170-024-13149-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13149-y