Abstract

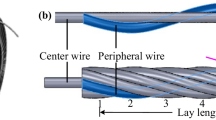

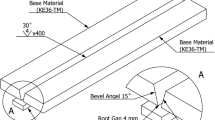

To raise narrow gap GMA welding efficiency while ensuring weld formation, the present work presents a thick-wire swing arc narrow gap GMA welding process assisted by cold wires. This process employs the thick wire and the pre-embedded cold wires to jointly increase the welding efficiency while improving the groove sidewall penetration by the swing arc. Two types of thick wires, conventional single-strand welding wire (SWW) and cable-type welding wire (CWW), are respectively used as main wire. After solving the series arc problem during CWW arc-igniting, the effects of the pre-embedded wire layer number on narrow gap weld formation and welding efficiency are investigated for thick-wire welding. Experimental results show that the weld thickness and the sidewall penetration do not obviously change with increasing the layer number of cold wires, while the weld layer height significantly grows. Additionally, the SWW weld formation looks more sound. Compared to thin-wire welding, the SWW and CWW thick-wire welding without the cold wire raises the deposition rate by about 38% and 58%, respectively. When pre-embedding two layers of cold wires, the increased percentage of the deposition rate further rises respectively to about 81% and 112%. These thus demonstrate the effectiveness of the developed process in addition to the higher efficiency of the CWW welding.

Similar content being viewed by others

Data availability

Not applicable.

References

Iwata S, Murayama M, Kojima Y (2009) Application of narrow gap welding process with high speed rotating arc to box column joints of heavy thick plates. JFE Tech Rep 14:16–21

Murayama M, Oazamoto D, Ooe K (2015) Narrow gap gas metal arc (GMA) welding technologies. JFE Tech Rep 20:147–153

Yin T, Wang J, Zhao H, Zhou L, Xue Z, Wang H (2022) Research on filling strategy of pipeline multi-layer welding for compound narrow gap groove. Materials 15(17):5967. https://doi.org/10.3390/ma15175967

Su N, Wang J, Xu G, Zhu J, Wang JY (2022) Infrared visual sensing detection approach of swing arc narrow gap weld deviation based on outlier data filtering. IEEE Sens J 22(16):16339–16350. https://doi.org/10.1109/JSEN.2022.3189681

Wang JY, Ren YS, Yang F, Guo HB (2007) Novel rotation arc system for narrow gap MAG welding. Sci Technol Weld Joi 12(6):505–507. https://doi.org/10.1179/174329307X213756

Guo N, Lin SB, Zhang L, Yang CL (2009) Metal transfer characteristics of rotating arc narrow gap horizontal GMAW. Sci Technol Weld Joi 14(8):760–764. https://doi.org/10.1179/136217109x12505932584655

Wang JY, Zhu J, Fu P, Su RJ, Han W, Yang F (2012) A swing arc system for narrow gap GMA welding. ISIJ Int 52(1):110–114. https://doi.org/10.2355/isijinternational.52.110

Wang JY, Zhu J, Zhang C, Wang N, Su RJ, Yang F (2015) Development of swing arc narrow gap vertical welding process. ISIJ Int 55(5):1076–1082. https://doi.org/10.2355/isijinternational.55.1076

Xu WH, Lin SB, Fan CL, Yang CL (2015) Prediction and optimization of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int J Adv Manuf Technol 79:183–196. https://doi.org/10.1007/s00170-015-6818-7

Kang YH, Na SJ (2003) Characteristics of welding and arc signal in narrow groove gas metal arc welding using electromagnetic arc oscillation. Weld J 82(5):93/S-99/S

Costa Assunção PD, Ribeiro RA, Dos Santos EBF, Gerlich AP, Braga EM (2017) Feasibility of narrow gap welding using the cold-wire gas metal arc welding (CW-GMAW) process. Weld World 61:659–666. https://doi.org/10.1007/s40194-017-0466-5

Ribeiro RA, Assunção PDC, Dos Santos EBF, Filho AAC, Braga EM, Gerlich AP (2019) Application of cold wire gas metal arc welding for narrow gap welding (NGW) of high strength low alloy steel. Materials 12(3):335. https://doi.org/10.3390/ma12030335

Wang JY, Jiang Y, Zhu J, Liu D, Xu G, Li W (2023) Development of swing arc narrow gap GMAW process assisted by swaying wire. J Mater Process Technol 318:118004. https://doi.org/10.1016/j.jmatprotec.2023.118004

Yang ZD, Chen YT, Zhang ZW, Fang CF, Xu K, He P, Zhang ZD (2022) Research on the sidewall penetration mechanisms of cable-type welding wire narrow gap GMAW process. Int J Adv Manuf Technol 120:2443–2455. https://doi.org/10.1007/s00170-022-08866-1

Fang CF, He B, Zhao ZC, Hu XG, Jiang JZ, Shi Z (2013) Comparative study on processing property between CWW CO2 gas shielded welding and SAW. J Iron Steel Res Int 20(4):81–86. https://doi.org/10.1016/S1006-706X(13)60087-4

Wang JK, Shen QK, Kong XD, Chen XZ (2021) Arc additively manufactured 5356 aluminum alloy with cable-type welding wire: microstructure and mechanical properties. J Mater Eng Perform 30:7472–7478. https://doi.org/10.1007/s11665-021-05905-y

Shi LN, Song YL, Xiao TJ, Ran GW (2012) Physical characteristics of striking arc ignition process. Chin J Mech Eng 25(4):786–791. https://doi.org/10.3901/CJME.2012.04.786

Si JJ, Rui XM, Wang JC, Liu B, Liu SC (2020) Experimental analysis on influence of temperature and bolted torque to DC contact resistance of terminal connector in UHV valve hall. CSEE JPES 6(4):858–866. https://doi.org/10.17775/CSEEJPES.2019.00700

Funding

This research is supported by the National Natural Science Foundation of China (grant no. 51875268).

Author information

Authors and Affiliations

Contributions

Zhengyu Zhu and Jiayou Wang contributed to the conception and design of the research. Data curation was performed by Zhengyu Zhu, Jiayou Wang, Shubin Liu, and Yuqing Jiang. Funding acquisition was provided by Jiayou Wang. The experimental design was performed by Zhengyu Zhu, Jiayou Wang, Shubin Liu, and Jie Zhu. The investigation was completed by Zhengyu Zhu, Xuyang Li, Luxiao Zhang, and Yuqing Jiang. The manuscript was written by Zhengyu Zhu, Jiayou Wang, Shubin Liu, and Yuqing Jiang. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, Z., Wang, J., Liu, S. et al. Thick-wire swing arc narrow gap GMA welding assisted by pre-embedding cold wires. Int J Adv Manuf Technol 131, 301–313 (2024). https://doi.org/10.1007/s00170-024-13093-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13093-x