Abstract

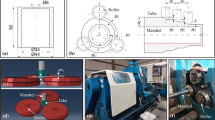

2219 aluminum alloy thin-walled tubes were fabricated by multi-pass spinning process, and then heat treatments were employed to optimize the mechanical properties of the spun tubes. It is shown that severe deformation during the spinning leads to the formation of large number of nanoscale subgrains, which causes the decrease of work hardening rate, ultimate tensile strength, and fracture strain. The solid solution at 530℃/30 min results in the full recrystallization and leads to the disappearance of the nanoscale subgrains. Besides, the micron scale precipitates in the as-spun tubes are refined to be nanoscale via the further aging process conducted at 175℃/18 h. It is why the ultimate strength of the tubes is enhanced from 245 to 435 MPa. By using of the spun tubes, 2219 aluminum alloy bellows with four circumferential waves were successfully formed by multi-step single wave hydroforming process.

Similar content being viewed by others

References

Fan XB, Yuan SJ (2022) Innovation for forming aluminum alloy thin shells at ultra-low temperature by the dual enhancement effect. Int J Extreme Manuf 4(3):033001

Zeng X, Fan XG, Li HW, Zhan M, Li SH, Ren TW, Wu KQ (2020) Grain refinement in hot working of 2219 aluminum alloy: on the effect of deformation mode and loading path. Mat Sci Eng A 794:139905

Li ZX, Zhan M, Fan XG, Wang XX, Ma F (2020) Age hardening behaviors of spun 2219 aluminum alloy component. J Mater Res Technol 9(3):4706–4716

Pei YB, Hao YG, Zhao J, Yang JT, Teng BG (2023) Texture evolution prediction of 2219 aluminum alloy sheet under hydro-bulging using cross-scale numerical modeling. J Mater Sci Technol 149:190–204

Yuan SJ (2021) Fundamentals and processes of fluid pressure forming technology for complex thin-walled components. Eng 7(3):358–366

Wang CY, Wu J, Chen JH, Xiang ZW, Sheng XT (2020) Stability research on spinning of ultra-thin-wall aluminum alloy tube. Sn Appl Sci 2(5):941

Chen YZ, Zhao SL, Wang H, Li J, Hua L (2023) Theoretical analysis and verification on plastic deformation behavior of rocket nozzle using a novel tube upsetting-bulging method. Mater 16(4):1680

Wang PY, Wan GH, Jin JG, Wang YC, Xiang N, Zhao XK, Zhao XN, Yuan BX, Wang ZJ (2022) Subregional flexible-die control in magnetorheological pressure forming. J Mater Process Tech 307:117698

Zheng FL, Chen HS, Wang WX, Liu RA, Lian JJ (2022) Effect of spinning deformation on microstructure evolution and mechanical properties of Al-Zn-Mg-Cu (7075) Alloy. J of Materi Eng and Perform 31(8):6473–6486

Music O, Allwood JM, Kawai K (2010) A review of the mechanics of metal spinning. J Mater Process Tech 210:3–23

Gondo S, Arai H, Kajino S, Nakano S (2021) Evolution of strain state of a rolled aluminum sheet in multi-pass conventional spinning. J Manuf Sci E 143(6):061011

Yuan SJ, Hu ZL, Wang XS (2012) Formability and microstructural stability of friction stir welded aluminum alloy tube during subsequent spinning and post weld heat treatment. Mat Sci Eng A 558:586–591

Zhao GY, Lu CJ, Zhang RY, Guo ZH, Zhang MY (2016) Uneven plastic deformation behavior of high-strength cast aluminum alloy tube in multi-pass hot power backward spinning. Int J Adv Manuf Tech 88(1–4):907–921

Wu H, Xu WC, Shan DB, Jin BC (2019) Mechanism of increasing spinnability by multi-pass spinning forming – analysis of damage evolution using a modified GTN model. Int J Mech Sci 159:1–19

Roy BK, Korkolis YP, Arai Y, Araki W, Iijima T, Kouyama J (2020) Experimental and numerical investigation of deformation characteristics during tube spinning. Int J Adv Manuf Tech 110(5–6):1851–1867

Xia QX, Xiao GF, Long H, Cheng XQ, Sheng XF (2014) A review of process advancement of novel metal spinning. Int J Mach Tool Manu 85:100–121

Eftekhari M, Faraji G, Bahrami M, Baniassadi M (2021) Hydrostatic tube cyclic extrusion compression as a novel severe plastic deformation method for fabricating long nanostructured tubes. Met Mater Int 28(7):1725–1740

Tsuji N, Ito Y, Saito Y, Minamino Y (2002) Strength and ductility of ultrafine grained aluminum and iron produced by ARB and annealing. Scripta Mater 47(12):893–899

Yang QY, Zhou YL, Tan YB, Xiang S, Ma M, Zhao F (2021) Effects of microstructure, texture evolution and strengthening mechanisms on mechanical properties of 3003 aluminum alloy during cryogenic rolling. J Alloy Compd 884:161135

Chen SY, Li FS, Liu Q, Chen KH, Huang LP (2020) Effect of post-aging heat treatment on strength and local corrosion behavior of ultrafine-grained 2219 aluminum alloy. J Mater Eng Perform 29(5):3420–3431

Khan S, Hussain G, Ilyas M, Rashid H, Khan MI, Khan WA (2018) Appropriate heat treatment and incremental forming route to produce age-hardened components of Al-2219 alloy with minimized form error and high formability. J Mater Process Tech 256:262–273

He HL, Yi YP, Huang SQ, Zhang YX (2019) An improved process for grain refinement of large 2219 aluminum alloy rings and its influence on mechanical properties. J Mater Sci Technol 35:55–63

Dong F, Yi YP, Huang SQ, He HL, Huang JW, Wang CG, Huang K (2021) Refinement of second-phase particles and grain structures of 2219 Al Cu alloy forgings using an improved thermomechanical treatment process. Mater Charact 173:110927

Mao XC, Yi YP, He H, Huang SQ, Guo WF (2020) Second phase particles and mechanical properties of 2219 aluminum alloys processed by an improved ring manufacturing process. Mat Sci Eng A 781:139226

Hua L, Zhang WP, Ma HJ, Hu ZL (2021) Investigation of formability, microstructures and post-forming mechanical properties of heat-treatable aluminum alloys subjected to pre-aged hardening warm forming. Int J Mach Tool Manu 169:103799

Gupta RK, Panda R, Mukhopadhyay AK, Kumar VA, Sankaravelayutham P, George KM (2015) Study of aluminum alloy AA2219 after heat treatment. Met Sci Heat Treat 57(5–6):350–353

Lin J, Wang XB, Lei YP, Ding JC, Li KL, Guo F (2021) Residual stress analysis and measurement in multi-layer bellows. J Manuf Process 72:179–194

Ra JH, Han SW, VanTyne CJ, Moon YH (2019) Manufacturing of a wire-reinforced aluminum tube via hydroforming process. Int J Mach Tool Manu 143:1–15

Bakhshi-Jooybari M, Elyasi M, Gorji A (2010) Numerical and experimental investigation of the effect of the pressure path on forming metallic bellows. P I Mech Eng B 224(1):95–101

Faraji G, Mashhadi MM, Norouzifard V (2009) Evaluation of effective parameters in metal bellows forming process. J Mater Process Tech 209(7):3431–3437

Jiang L, He Y, Lin Y et al (2020) Influence of process parameters on thinning ratio and fittability of bellows hydroforming. Int J Adv Manuf Technol 107:3371–3387

Author information

Authors and Affiliations

Contributions

Shiqiang Zhu: investigation, data curation, writing original draft; Kehuan Wang: methodology, writing and editing; Yongming Wang: forming experiment; Ruxun Shen: data curation, and validation; Gang Liu: conceptualization, and supervision; Shijian Yuan: editing and supervision.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhu, S., Wang, K., Wang, Y. et al. Spinning process of 2219 aluminum alloy tubes for used in hydroforming. Int J Adv Manuf Technol 130, 5479–5491 (2024). https://doi.org/10.1007/s00170-024-13070-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13070-4