Abstract

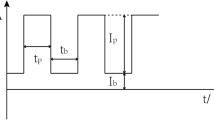

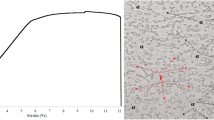

Ti-6Al-4V titanium alloy weldments were prepared using conventional TIG and fast-frequency double-pulse TIG (FFDP TIG) waveforms. Arc shape, microstructure, and mechanical properties of weldments were investigated. The arc core area of the FFDP TIG shrinks gradually, and the weldment fusion zone (FZ) width and heat-affected zone (HAZ) width are reduced by 18.2% and 31.3%, respectively. The molten pool intensive stirring effect and the heat input reduction by FFDP TIG waveform resulted in the prior β grain size decreased by 55.6% and the refinement of martensite αʹ structures. Microhardness and tensile strength of FFDP TIG weldment were higher than that of conventional TIG; the tensile strength and elongation reached 98.4% and 65.6% of the base metal, respectively. The results show that the FFDP-TIG process improves the Ti-6Al-4V weldment microstructure and mechanical properties and can perform excellently in practical applications.

Similar content being viewed by others

Data availability

The datasets generated and analyzed during the current study are available from the corresponding author upon reasonable request.

References

Kumar C, Das M, Paul CP, Bindra KS (2018) Comparison of bead shape microstructure and mechanical properties of fiber laser beam welding of 2 mm thick plates of Ti-6A1-4V alloy. Opt Laser Technol 105:306–321. https://doi.org/10.1016/j.optlastec.2018.02.021

Balasubramanian TS, Balakrishnan M, Balasubramanian V, Manickam MAM (2011) Effect of welding processes on joint characteristics of Ti-6Al-4V alloy. Sci Technol Weld Join 16:702–708. https://doi.org/10.1179/1362171811Y.0000000062

Kumar K, Masanta M, Sahoo SK (2019) Microstructure evolution and metallurgical characteristic of bead-on-plate TIG welding of Ti-6Al-4V alloy. J Mater Process Technol 265:34–43. https://doi.org/10.1016/j.jmatprotec.2018.10.002

Wang ZM, Jiang DH, Wu JW, Xu MJ (2020) A review on high-frequency pulsed arc welding. J Mater Process Technol 60:503–519. https://doi.org/10.1016/j.jmapro.2020.10.054

He LB, Li LM, Hao HW, Wu MS, Zhou RL (2013) Grain refinement and high performance of titanium alloy joint using arc-ultrasonic gas tungsten arc welding. Sci Technol Weld Join 11:72–74. https://doi.org/10.1179/174329306X77083

Wang YJ, Yu C, Lu H, Chen JM (2020) Research status and future perspectives on ultrasonic arc welding technique. J Mater Process Technol 58:936–954. https://doi.org/10.1016/j.jmapro.2020.09.005

Leary RK, Merson E, Birmingham K (2010) Microstructural and microtextural analysis of InterPulse GTCAW welds in Cp-Ti and Ti-6Al-4V. Mat Sci Eng A-Struct 527:7694–7705. https://doi.org/10.1016/j.msea.2010.08.036

Li L, Yang MX, Qi BJ, Liu H (2019) Study of high frequency pulsed arc on molten pool thermal properties of Ti-6Al-4V. J Mater Process Technol 38:308–312. https://doi.org/10.1016/j.jmapro.2019.01.034

Wang DQHC, Lu H (2020) Numerical analysis of ultrasonic waves in the gas tungsten arc welding (GTAW) with ultrasonic excitation of current. Int J. Heat Mass Transf 158:119847. https://doi.org/10.1016/j.ijheatmasstransfer.2020.119847

Li W, Lv GC, Wang Q, Huang ST (2020) Arc characteristics and weld bead microstructure of Ti-6Al-4V titanium alloy in ultra-high frequency pulse gas tungsten arc welding (UHFP-GTAW) process. Mater Sci 26:426–431. https://doi.org/10.5755/j01.ms.26.4.22329

Kumar A, DebRoy T (2003) Calculation of three-dimensional electromagnetic force field during arc welding. J Appl Phys 94:1267–1277. https://doi.org/10.1063/1.1587006

Chen C, Wei XQ, Zhao Y, Yan K, Jia ZJ, He YX (2018) Effects of helium gas flow rate on arc shape, molten pool behavior and penetration in aluminum alloy DCEN TIG welding. J Mater Process Technol 25:696–702. https://doi.org/10.1016/j.jmatprotec.2017.12.029

Mx Y, Zheng H, Qi BJ, Yang Z (2017) Effect of arc behavior on Ti-6Al-4V welds during high frequency pulsed arc welding. J Mater Process Technol 243:9–15. https://doi.org/10.1016/j.jmatprotec.2016.12.003

Wang YP, Qi BJ, Cong BQ, Liu FJ (2017) Arc characteristics in double-pulsed VP-GTAW for aluminum alloy. J Mater Process Technol 249:89–95. https://doi.org/10.1016/j.jmatprotec.2017.05.027

Li L, Yang MX, Qi BJ (2019) Study of high frequency pulsed arc on molten pool thermal properties of Ti-6Al-4V. J Mater Process Technol 38:308–312. https://doi.org/10.1016/j.jmapro.2019.01.034

Yang MX, Yang Z, Qi BJ (2015) Effect of fluid in molten pool on the welds with Ti-6Al-4V during pulsed arc welding. Int J Adv Manuf Technol 81(5–8):1007–1016. https://doi.org/10.1007/s00170-015-7272-2

Yang Z, Qi BJ, Cong BQ, Liu FJ, Yang MX (2015) Microstructure, tensile properties of Ti-6Al-4V by ultra high pulse frequency GTAW with low duty cycle. J Mater Process Technol 216:37–47. https://doi.org/10.1016/j.jmatprotec.2014.08.026

Vaithiyanathan V, Balasubramanian V, Malarvizhi S, Vijay P (2019) High temperature tensile properties and microstructural characterization of gas tungsten constricted arc welded Ti-6Al-4V alloy[J]. Mater Res Express 6(9) https://doi.org/10.1088/2053-1591/ab3491

Chen C, Fan CL, Cai XY, Lin SB, Liu Z, Fan QK (2019) Investigation of formation and microstructure of Ti-6Al-4V weld bead during pulse ultrasound assisted TIG welding. J Mater Process Technol 46:241–247. https://doi.org/10.1016/j.jmapro.2019.09.014

Wu JW, Wang ZM, Lin SB, Xie ZC, Xu MJ, Tian JY, Guo CF (2022) Effect of fast-frequency pulsed waveforms on the microstructure and mechanical properties of Ti-6Al-4V alloy welded by FFP-TIG. J Mater Res Technol 20:516–531. https://doi.org/10.1016/j.jmrt.2022.07.126

Wu JW, Xu MJ, Wang ZM, Lin SB, Zhang Q, Wu WM, Tian JY, Wang ZM (2023) Refining microstructures and enhancing mechanical properties of Inconel 718 weldment via fast-frequency double pulsed waveforms adopting in FFP-TIG. J Mater Process Technol 314 https://doi.org/10.1016/j.jmatprotec.2023.117882

Wang ZM, Gui ZX, Wu JW, Zhang Q, Wu XM, Lin SB, Tian JY, Guo CF (2023) Microstructure and high-temperature mechanical properties of Inconel 718 superalloy weldment affected by fast-frequency pulsed TIG welding. J Manuf Process 89:338–348. https://doi.org/10.1016/j.jmapro.2023.01.076

Babu NK, Raman S, Mythili R, Saroja S (2007) Correlation of microstructure with mechanical properties of TIG weldments of Ti-6Al-4V made with and without current pulsing. Mater Des 58(7):581–587. https://doi.org/10.1016/j.matchar.2006.07.001

Sun QD, Sun J, Guo K, Waqar S, Liu JW, Wang LS (2022) Influences of processing parameters and heat treatment on microstructure and mechanical behavior of Ti-6Al-4V fabricated using selective laser melting. Adv Manuf 10(4):520–540. https://doi.org/10.1007/s40436-022-00389-y

Lin JJ, Lv YH, Liu YX, Sun Z, Wang KB, Li ZG, Wu YX, Xu BS (2017) Microstructural evolution and mechanical property of Ti-6Al-4V wall deposited by continuous plasma arc additive manufacturing without post heat treatment. J Mech Behav Biomed Mater 69:19–29. https://doi.org/10.1016/j.jmbbm.2016.12.015

Tsai CJ, Wang LM (2014) Improved mechanical properties of Ti-6Al-4V alloy by electron beam welding process plus annealing treatments and its microstructural evolution. Mater Des 60:587–598. https://doi.org/10.1016/j.matdes.2014.04.037

Babu NK, Raman SGS, Murthy CVS, Reddy GM (2005) Influence of beam oscillation patterns on the structure and mechanical properties of Ti-6Al-4V electron beam weldments. Sci Technol Weld Join 10(5):583–590. https://doi.org/10.1179/174329305X57473

Mehdi B, Badji R, Ji V, Allili B, Bradai D, Deschaux-Beaume F, Soulié F (2016) Microstructure and residual stresses in Ti-6Al-4V alloy pulsed and unpulsed TIG welds. J Mater Process Technol 231:441–448. https://doi.org/10.1016/j.jmatprotec.2016.01.018

Brandl E, Schoberth A, Leyens C (2012) Morphology, microstructure, and hardness of titanium (Ti-6Al-4V) blocks deposited by wire-feed additive layer manufacturing (ALM). Mat Sci Eng A-Struct 532(Jan. 15):295–307. https://doi.org/10.1016/j.msea.2011.10.095

Gowthami G, Rao GVSN, Bhattacharjee A, Reddy GM (2020) Effect of arc pulsing in gas tungsten arc welding on microstructure and mechanical properties of Ti-6Al-4V-2.5Cu. Mat Sci Eng A-Struct 784 https://doi.org/10.1016/j.msea.2020.139318

Balasubramanian M, Jayabalan V, Balasubramanian V (2008) Effect of pulsed gas tungsten arc welding on corrosion behavior of Ti-6Al-4V titanium alloy. Mater Des 29(7):1359–1363. https://doi.org/10.1016/j.matdes.2007.06.009

Wang SG, Wu XQ (2012) Investigation on the microstructure and mechanical properties of Ti-6Al-4V alloy joints with electron beam welding. Mater Des 36:663–670. https://doi.org/10.1016/j.matdes.2011.11.068

Acknowledgements

The authors are thankful to the editors and reviewers.

Funding

This work was supported by the Science and Technology Planning Project of Guangdong Province [grant numbers 2021B1515420006, 2021B1515120026], the National Natural Science Foundation of China [grant numbers U23A20625, U2141216, 52305357], the National Key Research and Development Program of China [grant number 2023YFB3407702], the Shenzhen Science and Technology Plan Project [grant numbers KJZD20230923114614029], the State Key Lab of Advanced Welding and Joining [grant number AWJ-23M03], the Guangzhou Science and Technology Plan Project [grant number 2023A04J1584], and the National Defense Key Laboratory Fund Project [grant number 61420052022WD011].

Author information

Authors and Affiliations

Contributions

The conceptualization and manuscript were conducted by Yingwei Kuang. The experiments were designed by Jianjun Jia, Zeguang Zhu, and Zixiao Gui. Jiyu Tian and Zhenmin Wang performed funding acquisition and manuscript review. All the authors took part in the paper.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Written informed consent for publication was obtained from all participants.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kuang, Y., Jia, J., Zhu, Z. et al. Study on arc shape, weldment microstructure, and mechanical properties of Ti-6Al-4V welded by FFDP TIG waveform. Int J Adv Manuf Technol 130, 5269–5284 (2024). https://doi.org/10.1007/s00170-024-13067-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13067-z