Abstract

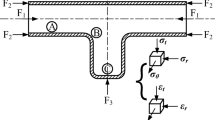

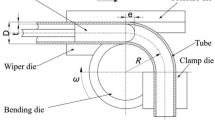

Pressure die boost effectively inhibits the thinning in the manufacturing process of aerospace tubes because it can produce a superposition effect of material compensation and friction. This phenomenon attracts lots of scholars. The related research uses the finite element and experimental method to analyze the tube thinning with and without a boost. The effects of boosting velocity and friction on the outer wall thickness of the tube are studied. Results show that frictional force generated by the boost and the material compensation effect combines to resist the outer wall thinning during the bending process. When the boosting velocity is higher than the tube bending linear velocity, the frictional force of the boost generates a specific compressive stress, which weakens the tensile stress during the bending process. In the meantime, the boosting effect transfers the material from the feed section to the bending section, compensating for the thinning of the tube wall during the bending process. A new theoretical model of tube bending and thinning under boost conditions is proposed to explain this coupling effect. The relative error between the new theoretical model and the experimental value is less than 1.5%, and the accuracy is improved by 5.3% compared with the traditional no-boost condition. The research overcomes the poor accuracy of the existing thinning model when fitting to boosted conditions and reveals the boosted effect’s mechanism on tube thinning.

Similar content being viewed by others

References

Shen X, Feng K, Xu H, Wang G, Zhang Y, Dai Y, Yun W (2023) Reliability analysis of bending fatigue life of hydraulic pipeline. Reliab Eng Syst Saf 231:109019. https://doi.org/10.1016/j.ress.2022.109019

Zhang F, Yuan Z, Zhang F, Liang N (2019) The analysis and estimation of vibration fatigue for pipe fitting in aviation hydraulic system. Eng Fail Anal 105:837–855. https://doi.org/10.1016/j.engfailanal.2019.07.038

Fang J, Ouyang F, Lu S, Wang K, Min X (2021) Effect of process parameters on wall thinning of high strength 21-6-9 stainless steel tube in numerical control bending. J Phys: Conf Ser 1885(2):022033. IOP Publishing. https://doi.org/10.1088/1742-6596/1885/2/022033

Board J T S (2009) Aircraft accident investigation report. available from, Ministry of Land, Infrastructure, Transport and Tourism, Japan, (accessed on 1 October, 2014)

Wang Q, Zhou W (2021) Burst capacity analysis of thin-walled pipe elbows under combined internal pressure and bending moment. Int J Press Vessels Pip 194:104562. https://doi.org/10.1016/j.ijpvp.2021.104562

Ashiba Y, Koizumi Y, Takahashi K, Hirano A, Takayamagi T, Fukuhara Y, Iwamatsu F (2020) Low-cycle fatigue behavior of stainless-steel elbows having local wall thinning. Mech Eng J 7(3):19–00582. https://doi.org/10.1299/mej.19-00582

Da-xin E, Ning RX, Gu T (2009) Analysis on the elastic-plastic deformation during tube-bending process. Acta Armamentarii 30(10):1353

Tang NC (2000) Plastic-deformation analysis in tube bending. Int J Press Vessels Pip 77(12):751–759. https://doi.org/10.1016/S0308-0161(00)00061-2

Fang J, Ouyang F, Lu S, Wang K, Min X, Xiao B (2021) Wall thinning behaviors of high strength 0Cr21Ni6Mn9N tube in numerical control bending considering variation of elastic modulus. Adv Mech Eng 13(5):16878140211021240. https://doi.org/10.1177/16878140211021241

Yang H, Li H, Zhan M (2010) Friction role in bending behaviors of thin-walled tube in rotary-draw-bending under small bending radii. J Mater Process Technol 210(15):2273–2284

Fang J, Lu S, Wang K, Xu J, Xu X, Yao Z (2013) Effect of mandrel on cross-section quality in numerical control bending process of stainless steel 2169 small diameter tube. Adv Mater Sci Eng 2013. https://doi.org/10.1155/2013/849495

Fang J, Lu SQ, Wang KL, Yao ZJ (2015) Deformation behaviors of 21–6-9 stainless steel tube numerical control bending under different friction conditions. J Cent South Univ 22(8):2864–2874. https://doi.org/10.1007/s11771-015-2819-9

Jiang Z, Zhan M, Yang H, Xu X, Li G (2011) Deformation behavior of medium-strength TA18 high-pressure tubes during NC bending with different bending radii. Chin J Aeronaut 24(5):657–664. https://doi.org/10.1016/S1000-9361(11)60077-0

Jiang W, Xie W, Song H, Lazarescu L, Zhang S, Banabic D (2020) A modified thin-walled tube push-bending process with polyurethane mandrel. Int J Adv Manuf Technol 106:2509–2521. https://doi.org/10.1007/s00170-019-04827-3

Murata M, Kuboki T, Takahashi K, Goodarzi M, Jin Y (2008) Effect of hardening exponent on tube bending. J Mater Process Technol 201(1–3):189–192. https://doi.org/10.1016/j.jmatprotec.2007.11.286

Wu W, Zhang P, Zeng X, Jin L, Yao S, Luo AA (2008) Bendability of the wrought magnesium alloy AM30 tubes using a rotary draw bender. Mater Sci Eng, A 486(1–2):596–601. https://doi.org/10.1016/j.msea.2007.09.033

Bardelcik A, Worswick MJ (2005) The effect of element formulation on the prediction of boost effects in numerical tube bending. In AIP Conference Proceedings (Vol. 778, No. 1, pp. 774–780). American Institute of Physics. https://doi.org/10.1063/1.2011316

Wang J, Agarwal R (2006) Tube bending under axial force and internal pressure. J Manuf Sci Eng 128(2):598–605. https://doi.org/10.1115/1.2112987

Zhang H, Hu Y (2022) Influence of pressure die’s boosting on forming quality in bending process of thin-walled tube. Int J Press Vessels Pip 196:104612. https://doi.org/10.1016/j.ijpvp.2022.104612

Li H, Yang H, Zhan M, Kou YL (2010) Deformation behaviors of thin-walled tube in rotary draw bending under push assistant loading conditions. J Mater Process Technol 210(1):143–158. https://doi.org/10.1016/j.jmatprotec.2009.07.024

Li H, Ma J, Liu BY, Gu RJ, Li GJ (2018) An insight into neutral layer shifting in tube bending. Int J Mach Tools Manuf 126:51–70. https://doi.org/10.1016/j.ijmachtools.2017.11.013

Tekkaya AE, Groche P, Kinsey BL, Wang ZG (2023) Stress superposition in metal forming. CIRP Ann 72(2):621–644. https://doi.org/10.1016/j.cirp.2023.04.090

Maaß F, Hahn M, Tekkaya AE (2022) Setting residual stresses in tensile stress-superposed incremental sheet forming. Key Eng Mater 926:655–662. https://doi.org/10.4028/p-232uip

Meya R, Löbbe C, Tekkaya AE (2019) Stress state analysis of radial stress superposed bending. Int J Precis Eng Manuf 20:53–66. https://doi.org/10.1007/s12541-019-00040-0

Fang J, Liang C, Lu SQ, Wang KL (2017) Effect of boosting velocity on forming quality of high-strength TA18 titanium alloy tubes in numerical control bending. Key Eng Mater 748:197–201. https://doi.org/10.4028/www.scientific.net/KEM.748.197

Wang W, Yang J, Dai J, Chen A (2023) EEMD-based videogrammetry and vibration analysis method for rotating wind power blades. Measurement 207:112423. https://doi.org/10.1016/j.measurement.2022.112423

Cheng X, Wang H, Abd El-Aty A, Tao J, Wei W, Qin Y, Guo X (2020) Cross-section deformation behaviors of a thin-walled rectangular tube of continuous varying radii in the free bending technology. Thin-Walled Structures 150:106670. https://doi.org/10.1016/j.tws.2020.106670

Poonaya S, Teeboonma U, Thinvongpituk C (2009) Plastic collapse analysis of thin-walled circular tubes subjected to bending. Thin-Walled Struct 47(6–7):637–645. https://doi.org/10.1016/j.tws.2008.11.005

He Y, Jing Y, Mei Z, Heng L, Yongle K (2009) 3D numerical study on wrinkling characteristics in NC bending of aluminum alloy thin-walled tubes with large diameters under multi-die constraints. Comput Mater Sci 45(4):1052–1067. https://doi.org/10.1016/j.commatsci.2009.01.010

Fang J, Lu S, Wang K, Liang C (2022) Wall thinning characteristics and prediction in numerical control bending of high strength Ti-3Al-2.5 V tube. Proc IME C J Mech Eng Sci 236(19):10321–10331. https://doi.org/10.1177/09544062221103691

Li H, Yang H, Zhan M, Sun Z, Gu R (2007) Role of mandrel in NC precision bending process of thin-walled tube. Int J Mach Tools Manuf 47(7–8):1164–1175. https://doi.org/10.1016/j.ijmachtools.2006.09.001

Derevyagina LS, Gordienko AI, Kashiro PO (2019) The influence of regimes of thermomechanical treatment on the structural-phase state, mechanical properties, and fracture toughness of low-alloy steel API 5L grade X52. Russ Phys J 61:1971–1977. https://doi.org/10.1007/s11182-019-01626-x

Pournara AE, Papatheocharis T, Karamanos SA, Perdikaris PC (2019) Mechanical behavior of dented steel pipes subjected to bending and pressure loading. J Offshore Mech Arct Eng 141(1):011702. https://doi.org/10.1115/1.4040835

Yang H, Gu R, Zhan M, Li H (2006) Effect of frictions on cross section quality of thin-walled tube NC bending. Trans Nonferrous Metals Soc China 16(4):878–886. https://doi.org/10.1016/S1003-6326(06)60344-0

Kahnamouei JT, Fattahi AM (2015) Experimental and numerical investigation of friction coefficient effects on defects in horizontal tube bending process. J Theor Appl Mech 53(4):837–846. https://doi.org/10.15632/jtam-pl.53.4.837

Sun H, Li H, Yang H, Ma J, Hao X, Fu MW (2023) Breaking through the bending limit of Al-alloy tubes by cryogenic effect controlled mechanical properties and friction behaviours. Int J Machine Tools Manuf 104111. https://doi.org/10.1016/j.ijmachtools.2023.104111

Tao R, Xu X, Fan Y, Xiao J, Wang Y, Wei L (2023) Differential flow velocities control method for push-bending of the thin-walled tube with a 0.9D bending radius by differential lubrication. Int J Adv Manuf Technol 124(10):3359–3369. https://doi.org/10.1007/s00170-022-10689-z

Lu S, Fang J, Wang K (2016) Plastic deformation analysis and forming quality prediction of tube NC bending. Chin J Aeronaut 29(5):1436–1444. https://doi.org/10.1016/j.cja.2016.03.009

Ma J, Li H, Fu MW (2021) Modelling of springback in tube bending: a generalized analytical approach. Int J Mech Sci 204:106516. https://doi.org/10.1016/j.ijmecsci.2021.106516

Funding

This research is financially supported by the Natural Science Foundation of Hunan Province, China (Grant No. 2023JJ30258, 2023JJ50018) and the Key Lab of Advanced Measurement and Test Technology for Aviation Propulsion System, Liaoning Province (Grant No. AMTAPS202301).

Author information

Authors and Affiliations

Contributions

Hao Fang: investigation, software, measurements, data analysis and interpretation, model development, writing—original draft, formal analysis. Zhineng Wang: conceptualization, methodology, writing—review and editing, project administration, supervision. Guangfu Bin: conceptualization, methodology, investigation, project administration, supervision. Weiming Lin: conceptualization, methodology, investigation. Yaochen Lin: conceptualization, methodology, investigation. Cong Trieu Tran: conceptualization, methodology, investigation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fang, H., Wang, Z., Bin, G. et al. Inhibiting thinning in tube bending by a superposition effect under a boosting movement. Int J Adv Manuf Technol 130, 5329–5344 (2024). https://doi.org/10.1007/s00170-024-13047-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13047-3