Abstract

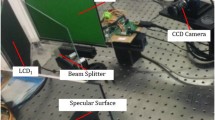

In this paper, a new deflectometry approach well suited for online inspection of specular reflective materials is proposed. Based on a simple hardware setup combining two linear light sources, a camera and a conveyor, our approach allows to detect, to localize, and to reconstruct in 3-D, surface aspect defects. It is easy to implement and particularly well suited for large objects in an industrial context (production line, for example). When the camera and light sources are fixed, the first step consists in calibrating the camera and estimating the light sources positions in the camera frame. Then, a full scanning of the object can be done, and the defects are detected in all images. In the last step, the defect is reconstructed in 3-D by slope integration. Thanks to a second light source added to the setup, the initial depth required by this kind of method is automatically estimated. Our approach has been tested in real experimental conditions with different plastic reflective parts and compared to the results provided by a metrology machine to validate the calibration and the reconstruction accuracy. The reconstructions of few millimeters defects on 4 different plastic parts show errors below 50 \(\upmu \)m. This accuracy meets the usual requirement in the industrial context as the 3D industrial metrology machine that we use to validate our method is more complex to handle with specular objects and has an accuracy of around 20 \(\upmu \)m.

Similar content being viewed by others

References

Khosravani MR, Bozic Z, Zolfagharian A, Reinicke T (2022) Failure analysis of 3D-printed PLA components: impact of manufacturing defects and thermal ageing. Eng Fail Anal 136:106214

Hoshikawa Y, Shirasu K, Higuchi R, Kawagoe Y, Tohmyoh H, Okabe T (2023) Experimental and numerical investigation of the relationship between material defects and elastoplasticity behavior of 3D-printed carbon-fiber-reinforced thermoplastics under compressive loading. Compos Sci Techno 241:110116

Rodriguez A, Gonzalez M, Pereira O, Lacalle L, Esparta M (2023) Edge finishing of large turbine casings using defined multi-edge and abrasive tools in automated cells. Int J Adv Manuf Technol 124(9):3149–3159

Ukar E, Lamikiz A, Martinez S, Tabernero I, Lacalle LN (2012) Roughness prediction on laser polished surfaces. J Mater Process Technol 212(6):1305–1313

Wyant JC (2002) White light interferometry. In: Holography: a tribute to yuri denisyuk and emmett leith, vol 4737, pp 98–107. International Society for Optics and Photonics

Jiang X, Wang K, Gao F, Muhamedsalih H (2010) Fast surface measurement using wavelength scanning interferometry with compensation of environmental noise. Appl Opt 49(15):2903–2909

Su P, Parks RE, Wang L, Angel RP, Burge JH (2010) Software configurable optical test system: a computerized reverse Hartmann test. Appl Opt 49(23):4404–4412

Bösemann, W.: Industrial photogrammetry-accepted metrology tool or exotic niche. International Archives of the Photogrammetry, Remote Sensing & Spatial Information Sciences 41 (2016)

Su T, Wang S, Parks RE, Su P, Burge JH (2013) Measuring rough optical surfaces using scanning long-wave optical test system. 1. Principle and implementation. Appl Opt 52(29):7117–7126

Takeda M, Mutoh K (1983) Fourier transform profilometry for the automatic measurement of 3-D object shapes. Appl Opt 22(24):3977–3982

Su X, Chen W (2001) Fourier transform profilometry: a review. Opt Lasers Eng 35(5):263–284

Kemao Q (2007) Two-dimensional windowed Fourier transform for fringe pattern analysis: principles, applications and implementations. Opt Lasers Eng 45(2):304–317

Huang L, Kemao Q, Pan B, Asundi AK (2010) Comparison of Fourier transform, windowed Fourier transform, and wavelet transform methods for phase extraction from a single fringe pattern in fringe projection profilometry. Opt Lasers Eng 48(2):141–148

Trumper I, Choi H, Kim DW (2016) Instantaneous phase shifting deflectometry. Opt Express 24(24):27993–28007

Su X, Chen W (2004) Reliability-guided phase unwrapping algorithm: a review. Opt Lasers Eng 42(3):245–261

Zhao M, Huang L, Zhang Q, Su X, Asundi A, Kemao Q (2011) Quality-guided phase unwrapping technique: comparison of quality maps and guiding strategies. Appl Opt 50(33):6214–6224

Manh The N, Young-Sik G, Hyug-Gyo R (2021) One-shot deflectometry for high-speed inline inspection of specular quasi-plane surfaces. Opt Lasers Eng 147

Niu Z, Zhang X, Ye J, Zhu Y, Min Xu M, Jiang X (2020) Flexible one-shot geometric calibration for off-axis deflectometry. Appl Opt 59(13):3819–3824

Liu Y, Huang S, Zhang Z, Gao N, Gao F, Jiang X (2017) Full-field 3D shape measurement of discontinuous specular objects by direct phase measuring deflectometry. Sci Rep 7(10293)

Xu Y, Wang Y, Gao F, Jiang X (2022) Segmentation phase measuring deflectometry for measuring structured specular surfaces. Int J Adv Manuf Technol 119(5)

Ren H, Gao F, Jiang X (2015) Improvement of high-order least-squares integration method for stereo deflectometry. Appl Opt 54(34):10249–10255

Nguyen MT, Ghim Y-S, Rhee H-G (2019) Single-shot deflectometry for dynamic 3D surface profile measurement by modified spatial-carrier frequency phase-shifting method. Sci Rep 9(1):1–15

Höfer S, Burke J, Heizmann M (2016) Infrared deflectometry for the inspection of diffusely specular surfaces. Adv Opt Technol 5(5–6):377–387

Meguenani A, Chambard J-P, Maillot Y, Cudel C (2019) Deflectometry based inline inspection of linearly moving plastic parts. In: Proceedings of the international conference on quality control by artificial vision (QCAV)

Zhang Z (2000) A flexible new technique for camera calibration. IEEE Trans Pattern Anal Mach Intell 22(11):1330–1334

Rapp HH (2012) Reconstruction of specular reflective surfaces using auto-calibrating deflectometry. PhD thesis, Karlsruher Institut fur Technologie

Ioffe S, Szegedy C (2015) Batch normalization: accelerating deep network training by reducing internal covariate shift. In: Proceedings of machine learning research, vol 37

Zhou L, Zhang C, Wu M (2018) D-LinkNet: LinkNet with pretrained encoder and dilated convolution for high resolution satellite imagery road extraction. In: Proceedings of the IEEE conference on computer vision and pattern recognition workshops, pp 182–186

Peng D, Zhang Y, Guan H (2019) End-to-end change detection for high resolution satellite images using improved unet++. Remote Sens 11(11):1382

Xu D, Zhang S, Zhang H, Mandic DP (2021) Convergence of the RMSProp deep learning method with penalty for nonconvex optimization. Neural Netw 139:17–23

Mukkamala MC, Hein M (2017) Variants of RMSProp and Adagrad with logarithmic regret bounds. In: International conference on machine learning, pp 2545–2553. PMLR

Dauphin Y, De Vries H, Bengio Y (2015) Equilibrated adaptive learning rates for non-convex optimization. Adv Neural Inf Process Syst 28

Daniel C, Taylor J, Nowozin S (2016) Learning step size controllers for robust neural network training. In: Thirtieth AAAI conference on artificial intelligence

Quéau Y, Durou J-D, Aujol J-F (2017) Normal integration: a survey. J Math Imaging Vis 60:576–593

Meguenani A, Tout K, Kohler S, Bazeille S, Chambard J-P, Cudel C (2021) Deflectometry based on light-field imaging. In: Proceedings of the international conference on quality control by artificial vision

Funding

This work was supported by the TRAC project under the grant FUI 24 (French Unique 373 Interministerial Fund).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study and to the manuscript preparation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bazeille, S., Meguenani, A., Tout, K. et al. A scanning deflectometry scheme for online defect detection and 3-D reconstruction of specular reflective materials. Int J Adv Manuf Technol 131, 245–259 (2024). https://doi.org/10.1007/s00170-024-13034-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-13034-8