Abstract

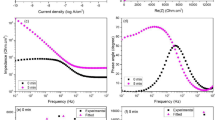

The surface characteristics and corrosion behavior of electropolished AISI 316L stainless steel specimens were analyzed. The influence of the electropolishing process parameters, such as voltage, temperature, time, cathode material, cathode geometry, and cathode–anode distance, was also evaluated using an electrolyte composed of sulfuric acid, phosphoric acid, and water. The surface characteristics of the specimens were determined by means of scanning electron microscopy, X-ray diffraction, microindentation tests, and contact profilometry. Corrosion tests were carried out using 3.5% w/v NaCl aqueous solution as a corrosive medium. The results indicate that the electropolishing process on AISI 316L greatly reduces the roughness of the samples when proper parameters are used. However, the waviness exhibits a more irregular behavior. It is also demonstrated that the use of stainless steel cathodes instead of copper cathodes allows obtaining surfaces with less roughness. Electropolishing produces the elimination of the deformed surface layer and, if present, of the martensite phase. This results in a decrease in surface hardness. The corrosion resistance of AISI 316L increases after the electropolishing process. In the case of cylindrical specimens, greater homogeneity in roughness parameters is obtained by using a cylindrical cathode concentric with the specimen instead of flat cathodes.

Similar content being viewed by others

References

McGuire M (2008) Austenitic stainless steels stainless Steels for Design Engineers. ASM International, Materials Park, OH

ASME-BPE (2022) Bioprocessing equipment. The American Society of Mechanical Engineers, New York, NY

Gabe DR (1972) Electropolishing of copper and copper-based alloys in ortho-phosphoric acid. Corros Sci 12(2):113–120. https://doi.org/10.1016/S0010-938X(72)90826-8

Habibzadeh S, Li L, Shum-Tim D, Davis EC, Omanovic S (2014) Electrochemical polishing as a 316L stainless steel surface treatment method: towards the improvement of biocompatibility. Corros Sci 87:89–100. https://doi.org/10.1016/j.corsci.2014.06.010

Pelleg J (1974) Electropolishing of titanium. Metallography 7(4):357–360. https://doi.org/10.1016/0026-0800(74)90015-9

Chandra A (2012) On the mechanism of niobium electropolishing. Master of Science, The Ohio State University. Retrieved from https://www.scopus.com/inward/record.uri?eid=2-s2.0-84983521322&partnerID=40&md5=19b3cc76deb5b716f4475dde9e02631b Scopus database

Yang G, Wang B, Tawfiq K, Wei H, Zhou S, Chen G (2017) Electropolishing of surfaces: theory and applications. Surf Eng 33(2):149–166. https://doi.org/10.1080/02670844.2016.1198452

Hensel KB (2002) Electropolishing. Met Finish 100:425–433. https://doi.org/10.1016/S0026-0576(02)82046-3

Han W, Fang F (2019) Fundamental aspects and recent developments in electropolishing. Int J Mach Tools Manuf 139:1–23. https://doi.org/10.1016/j.ijmachtools.2019.01.001

Łyczkowska-Widłak E, Lochyński P, Nawrat G (2020) Electrochemical Polishing of austenitic stainless steels. Materials 13(11):2557. https://doi.org/10.3390/ma13112557

Beamud-González EM, Núñez-López PJ, García-Plaza E (2023) Electropolishing stainless steel optimization using surface quality, dimensional accuracy, and electrical consumption criteria. Materials 16(5):1770. https://doi.org/10.3390/ma16051770

Mohan S, Kanagaraj D, Sindhuja R, Vijayalakshmi S, Renganathan NG (2001) Electropolishing of stainless steel—a review. Transactions of the IMF 79(4):140–142. https://doi.org/10.1080/00202967.2001.11871382

Tyagi P, Brent D, Saunders T, Goulet T, Riso C, Klein K, Moreno FG (2020) Roughness reduction of additively manufactured steel by electropolishing. Int J Adv Manuf Technol 106(3):1337–1344. https://doi.org/10.1007/s00170-019-04720-z

Han W, Fang F (2019) Electropolishing of 316L stainless steel using sulfuric acid-free electrolyte. J Manuf Sci Eng 141(10):101015. https://doi.org/10.1115/1.4044518

Han W, Fang F (2020) Two-step electropolishing of 316L stainless steel in a sulfuric acid-free electrolyte. J Mater Process Technol 279:116558. https://doi.org/10.1016/j.jmatprotec.2019.116558

Han W, Fang F (2020) Eco-friendly NaCl-based electrolyte for electropolishing 316L stainless steel. J Manuf Process 58:1257–1269. https://doi.org/10.1016/j.jmapro.2020.09.036

Kityk A, Pavlik V, Hnatko M (2023) Green electropolishing using choline chloride-based deep eutectic solvents: a review. J Mol Liq 392:123519. https://doi.org/10.1016/j.molliq.2023.123519

Rotty C, Mandroyan A, Doche ML, Hihn JY (2016) Electropolishing of CuZn brasses and 316L stainless steels: influence of alloy composition or preparation process (ALM vs. standard method). Surf Coat Technol 307:125–135. https://doi.org/10.1016/j.surfcoat.2016.08.076

Rokicki R, Hryniewicz T (2012) Enhanced oxidation–dissolution theory of electropolishing. Trans IMF 90(4):188–196. https://doi.org/10.1179/0020296712z.00000000031

Landolt D (1987) Fundamental aspects of electropolishing. Electrochim Acta 32(1):1–11. https://doi.org/10.1016/0013-4686(87)87001-9

Lochyński P, Charazińska S, Łyczkowska-Widłak E, Sikora A (2019) Electropolishing of stainless steel in laboratory and industrial scale. Metals 9(8):854. https://doi.org/10.3390/met9080854

Lee ES (2000) Machining characteristics of the electropolishing of stainless steel (STS316L). Int J Adv Manuf Technol 16(8):591–599. https://doi.org/10.1007/s001700070049

Shen M, Fang F (2023) Two-step electropolishing of internal surfaces of 316L stainless steel made by laser-based powder bed fusion. J Manuf Process 89:298–313. https://doi.org/10.1016/j.jmapro.2023.01.052

Chaghazardi Z, Wuthrich R (2020) Electropolishing of inside surfaces of stainless-steel tubing. ECS Meet Abstr MA2020-01(21):1285. https://doi.org/10.1149/MA2020-01211285mtgabs

Lee S-J, Lai J-J (2003) The effects of electropolishing (EP) process parameters on corrosion resistance of 316L stainless steel. J Mater Process Technol 140(1):206–210. https://doi.org/10.1016/S0924-0136(03)00785-4

Landolt D, Chauvy PF, Zinger O (2003) Electrochemical micromachining, polishing and surface structuring of metals: fundamental aspects and new developments. Electrochim Acta 48(20):3185–3201. https://doi.org/10.1016/S0013-4686(03)00368-2

ASTM E 1558-99 (1999) Standard guide for electrolytic polishing of metallographic specimens. ASTM International, West Conshohocken, PA

Hirschorn B, Orazem ME, Tribollet B, Vivier V, Frateur I, Musiani M (2010) Determination of effective capacitance and film thickness from constant-phase-element parameters. Electrochim Acta 55(21):6218–6227. https://doi.org/10.1016/j.electacta.2009.10.065

Hryniewicz T, Rokosz K, Rokicki R (2008) Electrochemical and XPS studies of AISI 316L stainless steel after electropolishing in a magnetic field. Corros Sci 50(9):2676–2681. https://doi.org/10.1016/j.corsci.2008.06.048

ur Rahman Z, Deen KM, Cano L, Haider W (2017) The effects of parametric changes in electropolishing process on surface properties of 316L stainless steel. Appl. Surf. Sci. 410:432–444. https://doi.org/10.1016/j.apsusc.2017.03.081

Acknowledgements

The authors wish to thank the companies Tecmar S.A. and FG Ingeniería S.A. for the donation of the AISI 316L plates, pipes, bars, pipe accessories, and discarded parts.

Funding

This work was supported by the Universidad Nacional de Mar del Plata (Grant number 15/G525).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design, material preparation, data collection, and analysis. The first draft of the manuscript was written by Diego Colombo, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Colombo, D., Carro, I., Catellani, C. et al. Electropolishing of AISI 316L: effect on surface characteristics and corrosion behavior. Int J Adv Manuf Technol 130, 4207–4219 (2024). https://doi.org/10.1007/s00170-024-12972-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-024-12972-7