Abstract

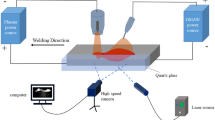

Enhancing penetration ability is a critical issue in plasma arc welding (PAW). A novel welding torch is developed to create a secondary compression by adding a radial gas flow below the nozzle of the PAW torch, which acts on the plasma arc in the vertical direction. The role and action mechanism of radial gas is studied by experimental test and simulation calculation. Adding the radial gas will enhance the arc column contraction, resulting in increased arc pressure and voltage; simulation results indicate that the addition of radial gas improves the physical characteristics such as arc plasma velocity, temperature, current density, magnetic flux intensity, and radial Lorentz force when compared with conventional PAW; spot welding proves that the re-constricted plasma arc with radial gas achieves greater penetration depth. These findings suggest that the addition of radial gas flow is an effective method for controlling and improving the penetration ability of the plasma arc.

Similar content being viewed by others

Data availability

All data supporting the fndings of this study are included in this article.

References

Liu ZM, Cui SL, Luo Z, Zhang CZ, Wang ZM, Zhang YC (2016) Plasma arc welding: process variants and its recent developments of sensing, controlling and modeling. J Manuf Process 23:315–327

Irving B (1992) Plasma arc welding takes on the advanced solid rocket motor. Weld J 71:49–52

Martikainen JK, Moisio TJI (1993) Investigation of the effect of welding parameters on weld quality of plasma arc keyhole welding of structural steels. Weld J 72:329–340

Duan XM, Li Q, Xie WR, Yang XD (2023) Wire arc metal additive manufacturing using pulsed arc plasma (PAP-WAAM) for effective heat management. J Mater Process Technol 311:117806

Wang YH, Konovalov S, Chen XZ, Singh RA, Jayalakshmi S (2022) Research on plasma arc additive manufacturing of Inconel 625 Ni–Cu functionally graded materials. Mat Sci Eng A-Struct 835:143796

Teker T, Özdemir N (2012) Weldability and joining characteristics of AISI 430/AISI 1040 steels using keyhole plasma arc welding. Int J Adv Manuf Technol 63:117–128

Sahoo A, Tripathy S (2021) Development in plasma arc welding process: a review. Mater Today: Proc 41:363–368

Wu CS, Wang L, Ren WJ, Zhang XY (2014) Plasma arc welding: process, sensing, control and modeling. J Manuf Process 16:74–85

Medellin-Castillo HI, de Lange DF, Ramirez-Cardona F, Garcia-Zugasti PD (2013) Weld quality analysis and evaluation of plasma arc welds in electrical stators. Int J Adv Manuf Technol 64:737–747

Li Y, Feng YH, Zhang XX, Wu CS (2018) An evolutionary keyhole-mode heat transfer model in continuous plasma arc welding. Int J Heat Mass Transfer 117:1188–1198

Liu ZM, Wu CS, Chen J (2013) Sensing dynamic keyhole behaviors in controlled-pulse keyholing plasma arc welding. Weld J 92:381–389

Zhang SB, Zhang YM (2001) Efflux plasma charge-based sensing and control of joint penetration during keyhole plasma arc welding. Weld J 80:157–162

Zhang YM, Liu YC (2003) Modeling and control of quasi-keyhole arc welding process. Control Eng Pract 11:1401–1411

Chen SJ, Xu B, Jiang F (2018) Blasting type penetrating characteristic in variable polarity plasma arc welding of aluminum alloy of type 5A06. Int J Heat Mass Transfer 118:1293–1306

Li YF, Tian SS, Wu CS, Tanaka M (2021) Experimental sensing of molten flow velocity, weld pool and keyhole geometries in ultrasonic-assisted plasma arc welding. J Manuf Process 64:1412–1419

Liu S, Liu ZM, Zhao XC, Fan XG (2020) Influence of cusp magnetic field configuration on K-TIG welding arc penetration behavior. J Manuf Process 53:229–237

Liu H, Qi BJ, Qi ZW, Zhu Y, Guo W, Yang MX, Mendez PF (2023) Mechanism of constriction in a high frequency pulsed welding arc. Int J Heat Mass Transfer 211:124251

Mcgee WF, Rybicki DJ, Waldron DJ (1993) Ternary gas plasma welding torch. United States Patent, p 5399831

Vredeveldt HL (2014) Increased power density plasma arc welding. Delf University of Technology, Delft

Li TQ, Yang XM, Chen L, Zhang Y, Lei YC, Yan JC (2020) Arc behaviour and weld formation in gas focusing plasma arc welding. Sci Technol Weld Join 25:329–335

Liu F, Liu ZM, Wang WB (2023) Arc characteristics and welding state in gas-focusing TIG. Int J Adv Manuf Technol 129:5335–5346

Yan ZY, Jiang F, Huang N, Zhang SL, Chen SJ (2019) Heat and pressure characteristics in hollow cathode centered negative pressure arc column. Appl Therm Eng 156:668–677

Liu ZM, Liu F, Zhao XC (2022) A novel arc plasma generating method by coaxial hybrid a ring arc to constraint arc: Principle and progress. J Manuf Process 82:362–373

Dai DS, Song YL, Zhang LP, Zhu YF, Zhang H (2003) Study on the pressure in plasma arc. Chin J Mech Eng 16:38–40

Murphy AB, Lowke JJ (2018) Heat transfer in arc welding. In: Handbook of Thermal Science and Engineering. Springer International Publishing, Berlin, pp 2657–2727

Jiang F, Yan ZY, Chen SJ, Lu ZY (2016) The energy distribution of electrode in hollow cathode centered negative pressure arc. J Manuf Process 24:138–144

Code availability

The method codes involved in this paper are not applicable.

Funding

This research received financial support from the National Natural Science Foundation of China (51975403, 52375373, 51975332).

Author information

Authors and Affiliations

Contributions

ZuMing Liu carried out the conception of the research and participated in the revision of the manuscript; Fei Liu carried out the analysis of data and drafted the manuscript; XingPei Wu completed the simulation calculation.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

All authors agree to participate in this work.

Consent for publication

All authors agree to publish.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, F., Wu, X. & Liu, Z. Enhancing plasma arc penetration ability with radial gas flow. Int J Adv Manuf Technol 130, 3619–3630 (2024). https://doi.org/10.1007/s00170-023-12935-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12935-4