Abstract

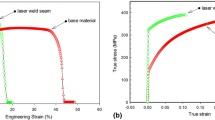

As an advanced sheet metal processing technology, fine blanking is usually used to produce precision parts for automobiles, aerospace, and other industries, but the forming process consumes huge energy. The previous research on fine blanking has mainly focused on improving the forming quality, but the analysis of process energy consumption from the process perspective is rare. Firstly, the energy consumption of the fine blanking process was analyzed theoretically, and a theoretical model was established. Then, the Ludwik hardening model and Oyane fracture criterion for 16MnCr5 were constructed. Next, the orthogonal experiment was designed to analyze the influence and degree of the main process parameters on surface quality and process energy consumption. Among them, blanking clearance, blank holder type, and blank holder force have the greatest influence on the size of the shear zone, energy consumption of deformation, and total process energy consumption, respectively. Furthermore, the influence mechanism of key process parameters on process energy consumption was deeply revealed from the perspective of deformation area, hydrostatic stress change, and material flow velocity, which provided a theoretical basis for green fine blanking. Finally, the fine blanking experiment was carried out to verify the great difference in surface quality and energy consumption under different process parameter combinations. This paper provides a theoretical direction for the fine blanking process, which can not only get high surface quality but also save energy consumption.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this published article.

References

BP statistical review of world energy (2021) https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy.html. Accessed 25 Apr 2022

Garwood TL, Hughes BR, Oates MR, Connor D, Hughes R (2017) A review of energy simulation tools for the manufacturing sector. Renew Sust Energy Rev 81(pt. 1):895–911

China statistical yearbook (2021) http://www.stats.gov.cn/tjsj/ndsj/2021/indexch.html. Accessed 25 Apr 2022

The paris agreement (2016) https://www.un.org/en/climatechange/paris-agreement. Accessed 25 Apr 2022

Responding to climate change: china’s policies and actions (2021) http://www.scio.gov.cn/ztk/dtzt/44689/47315/index.htm. Accessed 25 Apr 2022

Hou H, Li H, He L (2017) Effect of technological parameters on microstructure and accuracy of B1500HS steel parts in the hot blanking. Int J Adv Manuf Tech 95(1–2):1–13

Zhou KH (2005) Fine blanking handbook. National Defence Industry Press, China

Li L, Huang H, Li X, Liu ZF (2017) An improved energy matching method to utilize the potential energy of large-sized hydraulic press at multi-system level. Procedia CIRP 61:547–552

Xu ZC, Liu YX, Hua L, Wang X (2020) Energy improvement of fine blanking press by valve-pump combined controlled hydraulic system with multiple accumulators. J Clean Prod 257:120505

Liu YX, Xu ZC, Hua L, Zhao XH (2020) Analysis of energy characteristic and working performance of novel controllable hydraulic accumulator with simulation and experimental methods. Energy Convers Manage 221:113196

Xu ZC, Liu YX, Hua L, Zhao XH, Guo W (2019) Energy analysis and optimization of main hydraulic system in 10,000kN fine blanking press with simulation and experimental methods. Energy Convers Manage 181:143–158

Giuseppe I, Paolo CP, Francesco G, Rosa DL, Luca S (2015) Subtractive versus mass conserving metal shaping technologies: an environmental impact compariso. J Clean Prod 87:862–873

Giuseppe I, Paolo CP, Rosa DL, Luca S (2016) A methodology for evaluating the influence of batch size and part geometry on the environmental performance of machining and forming process. J Clean Prod 135:1611–1622

Noh JH, Hwang BB (2017) Work efficiency in a double cup extrusion process. Int J Precis Eng Man 18(3):407–414

Gao M, Huang H, Wang Q, Liu ZF, Li XY (2018) Energy consumption analysis on sheet metal forming: focusing on the deep drawing processes. Int J Adv Manuf Technol 96(9–12):3893–3907

Gao M, Wang Q, Li L, Ma ZL (2020) Energy-economizing optimization of magnesium alloy hot stamping process. Processes 8(2):186

Park HS, Nguyen TT, Dang XP (2016) Energy-efficient optimization of forging process considering the manufacturing history. Int J Pr Eng Man-GT 3(2):147–154

Nava P (2009) Minimizing carbon emissions in metal forming. Queen’s University, Canda, Ontario

Lmalghan R, Karthik RMC, Arunkumar S (2018) Application of particle swarm optimization and response surface methodology for machining parameters optimization of aluminium matrix composites in milling operation. J Braz Soc Mech SCI 39(9):3541–3553

Lmalghan R, Karthik RMC, Arunkumar S (2017) Machining parameters optimization of AA6061 using response surface methodology and particle swarm optimization. Int J Precis Eng Man 19(5):695–704

Peng T, Lv J, Majeed A, Liang XH (2020) An experimental investigation on energy-effective additive manufacturing of aluminum parts via process parameter selection. J Clean Prod 279:123609

Ma ZL, Gao M, Wang Q, Wang N, Lei Li, Liu CH, Liu ZF (2021) Energy consumption distribution and optimization of additive manufacturing. Int J Adv Manuf Technol 11:1–14

Mao HJ, Chen H, Liu YX, Ji KS (2022) A novel force variation fine-blanking process for the high-strength and low-plasticity material. Metals-Basel 12(3):458

Mao HJ, Fei Z, Liu YX, Hua L (2016) Numerical and experimental investigation of the discontinuous dot indenter in the fine-blanking process. J Manuf Process 24:90–99

Kuo CC, Liu KW, Li TC, Wu DY, Lin BT (2021) Numerical simulation and optimization of fine-blanking process for copper alloy sheet. Int J Adv Manuf Technol 119(1–2):1283–1300

Luo C, Chen Z, Zhou K, Yang XR, Zhang XL (2017) A novel method to significantly decrease the die roll during fine-blanking process with verification by simulation and experiments. J Mater Process Tech 250:254–260

Tang B, Liu YX, Mao HJ (2017) Investigation of a novel modified die design for fine-blanking process to reduce the die-roll size. Procedia Eng 207:1546–1551

Liu YX, Tang B, Hua L, Mao HJ (2018) Investigation of a novel modified die design for fine-blanking process to reduce the die-roll size. J Mater Process Tech 260:30–37

Wang ZF, Liu XH (2009) Energy principle and it’s application in metal forming. Science Press, China

Hambli R, Reszka M (2002) Fracture criteria identification using an inverse technique method and blanking experiment. Int J Mech Sci 44(7):1349–1361

Xia QX, Zhou LK, Xiao GF, Chen XQ, Chen WP (2018) Ductile fracture criterion for metal shear spinning. J Mech Eng 54(14):66–73

Li H, Fu MW, Lu J, Yang H (2011) Ductile fracture: experiments and computations. Int J Plasticity 27(2):147–180

Acknowledgements

This work is grateful for the financial supports from the National Natural Science Foundation of China (52275371) and Technology Innovation Team Project of Hubei.

Author information

Authors and Affiliations

Contributions

Yanxiong Liu: conceptualization, methodology, supervision. Yijun Zhang: investigation, validation, writing—original draft. Kaisheng Ji: formal analysis. Can Yang: project administration, validation. Fei Yin: resources. Yanli Song: visualization. Lin Hua: funding acquisition.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Y., Ji, K., Zhang, Y. et al. Energy consumption analysis for the fine blanking process. Int J Adv Manuf Technol 130, 5743–5761 (2024). https://doi.org/10.1007/s00170-023-12917-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12917-6