Abstract

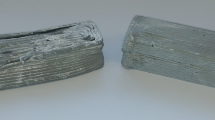

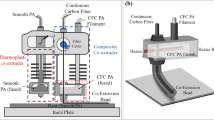

This study presents an integration of the level set-based two-material topology optimization method and the additive manufacturing technique for the design and fabrication of continuous carbon fiber (CCF)-reinforced composite structures. Firstly, optimal configurations of the resin material and fiber reinforcement are obtained to maximize the structural stiffness under desired volume constraints using the two-material topological optimization. After that, the level set-based cutting mesh method and triangulation scheme are employed to interpret these topological designs into stereolithography (STL) models with clear structural boundaries for the manufacturing. A customized pre-processing strategy is used to accurately determine the fiber placement regions from the optimal designs. Topological results are then fabricated using the CCF-based 3D printing method with prepreg carbon fibers. Subsequently, the performance of printed CCF-reinforced composite structures is investigated, using different resin materials: polylactic acid (PLA) and polyamide 12 with 10% carbon fiber (PA12_10CF). Experimental results indicate a significant increase in stiffness and strength of composite structures with fiber reinforcements for all resin materials, with an increase of 315% for PLA and 234% for PA12_10CF. Additionally, the CCF-reinforced composite structures made of PA12_10CF exhibit superior stiffness compared to those made of PLA with a double increment. The microstructural characteristics of damaged regions are examined using scanning electron microscope (SEM) images, which provide valuable insights into the behavior of resin and fiber materials.

Similar content being viewed by others

References

Bendsøe MP (1989) Optimal shape design as a material distribution problem. Structural Optimization 1(4):193–202. https://doi.org/10.1007/BF01650949

Sigmund O (2001) A 99 line topology optimization code written in Matlab. Struct Multidiscip Optim 21(2):120–127. https://doi.org/10.1007/s001580050176

Allaire G, Dapogny C, Frey P (2014) Shape optimization with a level set based mesh evolution method. Comput Methods Appl Mech Eng 282:22–53. https://doi.org/10.1016/j.cma.2014.08.028

Wang MY, Wang X, Guo D (2003) A level set method for structural topology optimization. Comput Methods Appl Mech Eng 192(1–2):227–246. https://doi.org/10.1016/S0045-7825(02)00559-5

Yamada T, Izui K, Nishiwaki S, Takezawa A (2010) A topology optimization method based on the level set method incorporating a fictitious interface energy. Comput Methods Appl Mech Eng 199(45–48):2876–2891. https://doi.org/10.1016/j.cma.2010.05.013

Xie YM, Steven GP (1993) A simple evolutionary procedure for structural optimization. Comput Struct 49(5):885–896. https://doi.org/10.1016/0045-7949(93)90035-C

Guo X, Zhang W, Zhong W (2014) Doing topology optimization explicitly and geometrically-a new moving morphable components based framework. J Appl Mech Trans ASME 81(8). https://doi.org/10.1115/1.4027609

Xie X, Wang S, Xu M, Wang Y (2018) A new isogeometric topology optimization using moving morphable components based on R-functions and collocation schemes. Comput Methods Appl Mech Eng 339:61–90. https://doi.org/10.1016/j.cma.2018.04.048

Sanders ED, Pereira A, Aguiló MA, Paulino GH (2018) Polymat: an efficient Matlab code for multi-material topology optimization. Struct Multidiscip Optim 58(6):2727–2759. https://doi.org/10.1007/s00158-018-2094-0

Sanders ED, Aguiló MA, Paulino GH (2018) Multi-material continuum topology optimization with arbitrary volume and mass constraints. Comput Methods Appl Mech Eng 340:798–823. https://doi.org/10.1016/j.cma.2018.01.032

Chau KN, Chau KN, Ngo T, Hackl K, Nguyen-Xuan H (2018) A polytree-based adaptive polygonal finite element method for multi-material topology optimization. Comput Methods Appl Mech Eng 332:712–739. https://doi.org/10.1016/j.cma.2017.07.035

Cui M, Chen H, Zhou J (2016) A level-set based multi-material topology optimization method using a reaction diffusion equation. CAD Computer Aided Design 73:41–52. https://doi.org/10.1016/j.cad.2015.12.002

Duan Z, Liu Y, Fan J, Long K, Xu B, Zhu J, Yan J (2023) Concurrent multi-material and multi-scale design optimization of fiber-reinforced composite material and structures for minimum structural compliance. Compos Struct 311. https://doi.org/10.1016/j.compstruct.2023.116796

Paolini A, Kollmannsberger S, Rank E (2019) Additive manufacturing in construction: A review on processes, applications, and digital planning methods. Addit Manuf 30. https://doi.org/10.1016/j.addma.2019.100894

Culmone C, Smit G, Breedveld P (2019) Additive manufacturing of medical instruments: A state-of-the-art review. Addit Manuf 27:461–473. https://doi.org/10.1016/j.addma.2019.03.015

Zhang H, Wang S, Zhang K, Wu J, Li A, Liu J, Yang D (2023) 3D printing of continuous carbon fibre reinforced polymer composites with optimised structural topology and fibre orientation. Compos Struct 313. https://doi.org/10.1016/j.compstruct.2023.116914

Mirzendehdel AM, Rankouhi B, Suresh K (2018) Strength-based topology optimization for anisotropic parts. Addit Manuf 19:104–113. https://doi.org/10.1016/j.addma.2017.11.007

Huang Y, Fang G, Zhang T, Wang CCL (2023) Turning-angle optimized printing path of continuous carbon fiber for cellular structures. Addit Manuf 68. https://doi.org/10.1016/j.addma.2023.103501

Fernandes RR, Werken N, Koirala, P, Yap T, Tamijani, AY, Tehrani M (2021) Experimental investigation of additively manufactured continuous fiber reinforced composite parts with optimized topology and fiber paths. Addit Manuf 44. https://doi.org/10.1016/j.addma.2021.102056

Huang Y, Tian X, Zheng Z, Li D, Malakhov AV, Polilov AN (2022) Multiscale concurrent design and 3D printing of continuous fiber reinforced thermoplastic composites with optimized fiber trajectory and topological structure. Compos Struct 285. https://doi.org/10.1016/j.compstruct.2022.115241

Wang Y, Zhang L, Daynes S, Zhang H, Feih S, Wang MY (2018) Design of graded lattice structure with optimized mesostructures for additive manufacturing. Mater Des 142:114–123. https://doi.org/10.1016/j.matdes.2018.01.011

Zhao J, Zhang M, Zhu Y, Li X, Wang L, Hu J (2019) A novel optimization design method of additive manufacturing oriented porous structures and experimental validation. Mater Des 163. https://doi.org/10.1016/j.matdes.2018.107550

Ichihara N, Ueda M (2023) 3D-printed high-toughness composite structures by anisotropic topology optimization. Compos B Eng 253. https://doi.org/10.1016/j.compositesb.2023.110572

Wang W, Feng D, Yang L, Li S, Wang CCL (2023) Topology optimization of self-supporting lattice structure. Addit Manuf 67. https://doi.org/10.1016/j.addma.2023.103507

Primo T, Calabrese M, Del Prete A, Anglani A (2017) Additive manufacturing integration with topology optimization methodology for innovative product design. Int J Adv Manuf Technol 93(1–4):467–479. https://doi.org/10.1007/s00170-017-0112-9

Ramadani R, Pal S, Kegl M, Predan J, Drstvenšek I, Pehan S, Belšak A (2021) Topology optimization and additive manufacturing in producing lightweight and low vibration gear body. Int J Adv Manuf Technol 113(11–12):3389–3399. https://doi.org/10.1007/s00170-021-06841-w

Nguyen KC, Tran P, Nguyen HX (2019) Multi-material topology optimization for additive manufacturing using polytree-based adaptive polygonal finite elements. Autom Constr 99:79–90. https://doi.org/10.1016/j.autcon.2018.12.005

Fidan I, Imeri A, Gupta A, Hasanov S, Nasirov A, Elliott A, Alifui-Segbaya F, Nanami N (2019) The trends and challenges of fiber reinforced additive manufacturing. Int J Adv Manuf Technol 102(5–8):1801–1818. https://doi.org/10.1007/s00170-018-03269-7

Liu G, Xiong Y, Zhou L (2021) Additive manufacturing of continuous fiber reinforced polymer composites: Design opportunities and novel applications. Compos Commun 27. https://doi.org/10.1016/j.coco.2021.100907

Lee J, Kim D, Nomura T, Dede EM, Yoo J (2018) Topology optimization for continuous and discrete orientation design of functionally graded fiber-reinforced composite structures. Compos Struct 201:217–233. https://doi.org/10.1016/j.compstruct.2018.06.020

Papapetrou VS, Patel C, Tamijani AY (2020) Stiffness-based optimization framework for the topology and fiber paths of continuous fiber composites. Compos B Eng 183. https://doi.org/10.1016/j.compositesb.2019.107681

Chen Y, Ye L (2021) Topological design for 3D-printing of carbon fibre reinforced composite structural parts. Compos Sci Technol 204. https://doi.org/10.1016/j.compscitech.2020.108644

Hsu Y-L, Hsu M-S, Chen C-T (2001) Interpreting results from topology optimization using density contours. Comput Struct 79(10):1049–1058. https://doi.org/10.1016/S0045-7949(00)00194-2

Hsu M-H, Hsu Y-L (2005) Interpreting three-dimensional structural topology optimization results. Comput Struct 83(4–5):327–337. https://doi.org/10.1016/j.compstruc.2004.09.005

Tang P-S, Chang K-H (2001) Integration of topology and shape optimization for design of structural components. Struct Multidiscip Optim 22(1):65–82. https://doi.org/10.1007/PL00013282

Koguchi A, Kikuchi N (2006) A surface reconstruction algorithm for topology optimization. Engineering with Computers 22(1):1–10. https://doi.org/10.1007/s00366-006-0023-0

Chacón JM, Bellido JC, Donoso A (2014) Integration of topology optimized designs into CAD/CAM via an IGES translator. Struct Multidiscip Optim 50(6):1115–1125. https://doi.org/10.1007/s00158-014-1099-6

Vogiatzis P, Chen S, Zhou C (2017) An open source framework for integrated additive manufacturing and level-set-based topology optimization. J Comput Inf Sci Eng 17(4). https://doi.org/10.1115/1.4037738

Ho-Nguyen-Tan T, Kim HG (2022) Level set-based topology optimization for compliance and stress minimization of shell structures using trimmed quadrilateral shell meshes. Comput Struct 259. https://doi.org/10.1016/j.compstruc.2021.106695

Ho-Nguyen-Tan T, Kim HG (2023) Stress-constrained concurrent two-scale topology optimization of functionally graded cellular structures using level set-based trimmed quadrilateral meshes. Struct Multidiscipl Optim 66(6). https://doi.org/10.1007/s00158-023-03572-2

Otomori M, Yamada T, Izui K, Nishiwaki S (2015) Matlab code for a level set-based topology optimization method using a reaction diffusion equation. Struct Multidiscip Optim 51(5):1159–1172. https://doi.org/10.1007/s00158-014-1190-z

Emmendoerfer H, Fancello EA (2016) Topology optimization with local stress constraint based on level set evolution via reaction-diffusion. Comput Methods Appl Mech Eng 305:62–88. https://doi.org/10.1016/j.cma.2016.02.024

Ho-Nguyen-Tan T, Kim HG (2022) An efficient method for shape and topology optimization of shell structures. Struct Multidiscipl Optim 65(4). https://doi.org/10.1007/s00158-022-03213-0

Nguyen SH, Kim H-G (2019) Level set based shape optimization using trimmed hexahedral meshes. Comput Methods Appl Mech Eng 345:555–583. https://doi.org/10.1016/j.cma.2018.11.006

Ho-Nguyen-Tan T, Kim H-G (2018) A new strategy for finite-element analysis of shell structures using trimmed quadrilateral shell meshes: A paving and cutting algorithm and a pentagonal shell element. Int J Numer Meth Eng 114(1):1–27. https://doi.org/10.1002/nme.5730

Nguyen SH, Kim HG (2020) Stress-constrained shape and topology optimization with the level set method using trimmed hexahedral meshes. Comput Methods Appl Mech Eng 366. https://doi.org/10.1016/j.cma.2020.113061

Nguyen SH, Sohn D, Kim HG (2022) A novel hr-adaptive mesh refinement scheme for stress-constrained shape and topology optimization using level-set-based trimmed meshes. Struct Multidiscipl Optim 65(2). https://doi.org/10.1007/s00158-021-03132-6

Cheng P, Peng Y, Li S, Rao Y, Le Duigou A, Wang K, Ahzi S (2023) 3D printed continuous fiber reinforced composite lightweight structures: A review and outlook. Compos B Eng 250:110450. https://doi.org/10.1016/j.compositesb.2022.110450

Azarov AV, Antonov FK, Golubev MV, Khaziev AR, Ushanov SA (2019) Composite 3D printing for the small size unmanned aerial vehicle structure. Compos B Eng 169:157–163. https://doi.org/10.1016/j.compositesb.2019.03.073

Ferreira I, Machado M, Alves F, Torres Marques A (2019) A review on fibre reinforced composite printing via FFF. Rapid Prototyping Journal 25(6):972–988. https://doi.org/10.1108/RPJ-01-2019-0004

Fedulov B, Fedorenko A, Khaziev A, Antonov F (2021) Optimization of parts manufactured using continuous fiber three-dimensional printing technology. Compos B Eng 227. https://doi.org/10.1016/j.compositesb.2021.109406

Acknowledgements

The authors would also like to express their thanks to Thai Nguyen University of Technology and the Sharetech Co., Ltd for supporting us to carry out our experiments.

Funding

This research was funded by the Vietnam Ministry of Education and Training, grant number B2022-TNA-27.

Author information

Authors and Affiliations

Contributions

Thuan N.-T. Ho: methodology, software, verification, investigation, computations, writing — original draft, writing — review and editing. Son H. Nguyen: resources, supervision, writing — review and editing. Van Thao Le: resources, writing — review and editing, visualization. Tien-Dat Hoang: conceptualization, methodology, investigation, resources, supervision, writing — review and editing, funding acquisition, project administration.

Corresponding author

Ethics declarations

Replication of results

No results are presented.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ho, T.NT., Nguyen, S.H., Le, V.T. et al. Coupling design and fabrication of continuous carbon fiber-reinforced composite structures using two-material topology optimization and additive manufacturing. Int J Adv Manuf Technol 130, 4277–4293 (2024). https://doi.org/10.1007/s00170-023-12913-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12913-w