Abstract

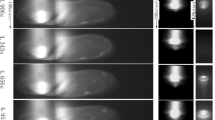

Gas tungsten arc welding (GTAW) is a popular technology for joining metallic parts with high stability and quality. However, many GTAW-related processes are conducted manually, which is time-consuming, and the weld quality strongly depends on the skill of the welder. Although various automatic GTAW methods and systems have been developed, controlling the weld quality remains a challenge because of the difficulties involved in predicting the weld quality, such as the penetration depth and backside bead geometry, during welding. Hence, this paper proposes an accurate and effective method for estimating the penetration depth through weld pool monitoring using a convolutional neural network (CNN) trained on weld pool images. The weld pool images contained several objects, each influencing the prediction accuracy. The CNN architecture and the structure of the fully connected layers (FCLs) also affected the prediction accuracy. To optimize the performance of the estimation model, the effects of each object in the weld pool image and the structure of the CNN architecture were analyzed and evaluated. The structure of the FCLs that outputted a quantitative penetration depth was optimized and evaluated through hyperparameter tuning. With the proposed method, the optimized model could quantitatively predict the penetration depth; the mean absolute error was 0.0516 mm, with an R2 value of 0.998. Accurately predicting the penetration depth can be employed in real-time weld quality control to ensure a sound weld back bead.

Similar content being viewed by others

References

Manorathna RP, Phairatt P, Ogun P, Widjanarko T, Chamberlain M, Justham L, Marimuthu S, Jackson MR (2014) Feature extraction and tracking of a weld joint for adaptive robotic welding. 13th Int Conf Control Autom Robot Vis (ICARCV) 1368–1372. https://doi.org/10.1109/ICARCV.2014.7064515

Kalyankar V, Bhoskar A, Deshmukh D, Patil S (2022) On the performance of metallurgical behaviour of Stellite 6 cladding deposited on SS316L substrate with PTAW process. Can Metall Q 61(2):130–144. https://doi.org/10.1080/00084433.2022.2031681

Bhoskar A, Kalyankar V, Deshmukh D (2023) Metallurgical characterisation of multi-track Stellite 6 coating on SS316L substrate. Can Metall Q 62(4):665–677. https://doi.org/10.1080/00084433.2022.2149009

Kalyankar V, Bhoskar A (2021) Influence of torch oscillation on the microstructure of Colmonoy 6 overlay deposition on SS304 substrate with PTA welding process. Metall Res Technol 118(4):406–418. https://doi.org/10.1051/metal/2021045

Kovacevic R, Zhang YM, Li L (1996) Monitoring of weld joint penetration based on weld pool geometrical appearance. Weld J 75(10):317–329

Bae K, Lee T, Ahn K (2001) An optical sensing system for seam tracking and weld pool control in gas metal arc welding of steel pipe. J Mater Process Technol 120(1):458–465. https://doi.org/10.1016/S0924-0136(01)01216-X

Wang Z, Zhang C, Pan Z, Wang Z, Liu L, Qi X, Mao S, Pan J (2018) Image segmentation approaches for weld pool monitoring during robotic arc welding. Appl Sci 8(12):2445. https://doi.org/10.3390/app8122445

Chen Z, Chen J, Feng Z (2017) Monitoring weld pool surface and penetration using reversed electrode images. Weld J 96:367–375

Kshirsagar R, Jones S, Lawrence J, Tabor J (2019) Prediction of bead geometry using a two-stage SVM–ANN algorithm for automated tungsten inert gas (TIG) welds. J Manuf Mater Process 3(2):39. https://doi.org/10.3390/jmmp3020039

Liu L, Chen H, Chen S (2019) Online monitoring of variable polarity TIG welding penetration state based on fusion of welding characteristic parameters and SVM. Trans Intell Weld Manuf 2(1):87–104. https://doi.org/10.1007/978-981-10-8740-0_5

Ouafi E, Bélanger R, Méthot J (2011) Artificial neural network-based resistance spot welding quality assessment system. Metall Res Technol 108(6):343–355. https://doi.org/10.1051/metal/2011066

Chokkalingham S, Chandrasekhar N, Vasudevan M (2012) Predicting the depth of penetration and weld bead width from the infra red thermal image of the weld pool using artificial neural network modeling. J Intell Manuf 23:1995–2001. https://doi.org/10.1007/s10845-011-0526-4

Mahadevan R, Jagan A, Pavithran L, Shrivastava A, Selvaraj S (2021) Intelligent welding by using machine learning techniques. Mater Today: Proc 46(2):7402–7410. https://doi.org/10.1016/j.matpr.2020.12.1149

Korat P, Sama M (2019) Implementation of artificial intelligence in TIG. Proc Int Conf Advancements Comput Manag (ICACM) 2019:1055–1062. https://doi.org/10.2139/ssrn.3462445

Hong Y, Chang B, Peng G, Yuan Z, Hou X, Xue B, Du D (2018) In-process monitoring of lack of fusion in ultra-thin sheets edge welding using machine vision. Sensors 18(8):2411. https://doi.org/10.3390/s18082411

Fang J, Wang K (2019) Weld pool image segmentation of hump formation based on fuzzy C-means and Chan-Vese model. J Mater Eng Perform 28:4467–4476. https://doi.org/10.1007/s11665-019-04168-y

Jiang C, Zhang F, Wang Z (2017) Image processing of aluminum alloy weld pool for robotic VPPAW based on visual sensing. IEEE Access 5:21567–21573. https://doi.org/10.1109/ACCESS.2017.2761986

Wen H, Zeng J, Bian Z, Hu A, Chu F, Mao Y (2022) Study of weld pool monitoring system based on spatial filtering. J Manuf Process 76:638–645. https://doi.org/10.1016/j.jmapro.2022.02.044

Cheng Y, Wang Q, Jiao W, Yu R, Chen S, Zhang Y, Xiao J (2020) Detecting dynamic development of weld pool using machine learning from innovative composite images for adaptive welding. J Manuf Process 5:908–915. https://doi.org/10.1016/j.jmapro.2020.04.059

Cheng Y, Chen S, Xiao J, Zhang Y (2021) Dynamic estimation of joint penetration by deep learning from weld pool image. Sci Technol Weld Join 26(4):279–285. https://doi.org/10.1080/13621718.2021.1896141

Li C, Wang Q, Jiao W, Johnson M, Zhang Y (2020) Deep learning-based detection of penetration from weld pool reflection images. Weld J 99:239–245. https://doi.org/10.29391/2020.99.022

Nomura K, Fukushima K, Matsumura T, Asai S (2021) Burn-through prediction and weld depth estimation by deep learning model monitoring the molten pool in gas metal arc welding with gap fluctuation. J Manuf Process 61:590–600. https://doi.org/10.1016/j.jmapro.2020.10.019

Shelhamer E, Long J, Darrell T (2017) Fully convolutional networks for semantic segmentation. IEEE Trans Pattern Anal Mach Intell 39:640–651. https://doi.org/10.1109/TPAMI.2016.2572683

Ronneberger O, Fischer P, Brox T (2015) U-Net: convolutional networks for biomedical image segmentation. Medical Image Computing and Computer-Assisted Intervention (MICCAI 2015) 234–241. https://doi.org/10.1007/978-3-319-24574-4_28

Cai W, Jiang P, Shu L, Geng S, Zhou Q (2022) Real-time identification of molten pool and keyhole using a deep learning-based semantic segmentation approach in penetration status monitoring. J Manuf Process 76:695–707. https://doi.org/10.1016/j.jmapro.2022.02.058

Yu R, Kershaw J, Wang P, Zhang Y (2021) Real-time recognition of arc weld pool using image segmentation network. J Manuf Process 72:159–167. https://doi.org/10.1016/j.jmapro.2022.02.058

Simonyan K, Zisserman A (2014) Very deep convolutional networks for large-scale image recognition. Int Conf Learn Representations (ICLR 2015) https://doi.org/10.48550/arXiv.1409.1556

He K, Zhang X, Ren S, Sun J (2016) Deep residual learning for image recognition. 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR) Proceedings. 770–778. https://doi.org/10.1109/cvpr.2016.90

Huang G, Liu Z, Maaten L, Weinberger K (2017) Densely connected convolutional networks, 2017 IEEE conference on computer vision and pattern recognition (CVPR). Proceedings: 2261–2269. https://doi.org/10.48550/arXiv.1608.06993

Tan M and Le Q (2019) EfficientNet: rethinking model scaling for convolutional neural networks. 36th International Conference on Machine Learning (ICML 2019). Proceedings: 6105–6114. https://doi.org/10.48550/arXiv.1905.11946

Zhang Y, Cao Z, Kovacevic R (1996) Numerical analysis of fully penetrated weld pools in gas tungsten arc welding. Proc Inst Mech Eng C J Mech Eng Sci 210(2):187–195. https://doi.org/10.1243/PIME_PROC_1996_210_185_02

Baek D, Moon H, Park S (2022) In-process prediction of weld penetration depth using machine learning-based molten pool extraction technique in tungsten arc welding. J Intell Manuf. https://doi.org/10.1007/s10845-022-02013-z

Brochu E, Cora V, Freitas N (2009) A tutorial on Bayesian optimization of expensive cost functions, with application to active user modeling and hierarchical reinforcement learning. arXiv: 1012.2599. https://doi.org/10.48550/arXiv.1012.2599

Wu Y, Johnson J (2021) Rethinking “Batch” in BatchNorm. ArXiv: 2105.07576. https://doi.org/10.48550/arXiv.2105.07576

Kingma D, Ba J (2015) Adam: a method for stochastic optimization. 3rd Int Conf Learn Representations (ICLR 2015). https://doi.org/10.48550/arXiv.1412.6980

Chollet F (2015) Keras. https://keras.io

Funding

This study has been conducted with support from the Korea Institute of Industrial Technology under “The dynamic parameter control based smart welding system module development for the complete joint penetration weld (KITECH EH-23–0007).”

Author information

Authors and Affiliations

Contributions

All authors contributed to the study’s conception and design. Material preparation, data collection, and analysis were performed by DB, HSM, and S-HP. The first draft of the manuscript was written by DB, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Baek, D., Moon, H.S. & Park, SH. Optimization of weld penetration prediction based on weld pool image and deep learning approach in gas tungsten arc welding. Int J Adv Manuf Technol 130, 2617–2633 (2024). https://doi.org/10.1007/s00170-023-12855-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12855-3