Abstract

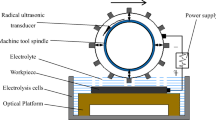

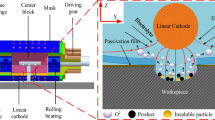

High efficiency and high quality machining of micro-bulged arrays on metal surfaces is a major technical challenge in the field of modern industry. In this paper, ultrasonic rolling pulse electrochemical micromachining (URPEMM) technology is proposed to prepare micro-bulged arrays on 304 stainless steel. Focusing on the widely used circular micro-bulges, distributions of electric field, temperature field and evolution processes of the circular, square and triangular sectional micro-bulges in URPEMM were analyzed by finite element analysis method(FEM). The simulation process of micro-bulges forming was experimentally verified. The results show that the current density and temperature increase first and then decrease, and the error between the experimental and simulation results of the micro-bulges is within 10%. The array micro-bulges with a diameter of 503.3 μm, a height of 33.5 μm, a roughness of 0.216 μm, and a microhardness of 305 Hv can be prepared in URPEMM. Furthermore, the surface tribological properties of circular micro-bulges decreases first and then increases with the increase of micro-bulged height, which was obtained through friction and wear tests, and the friction coefficient is minimum when the micro-bulged height is 10 μm.

Similar content being viewed by others

Data availability

The data used to support the fndings of this study are available from the corresponding author upon request.

References

Liang X, Guo ZW, Li Z, Qiu YK, Wang ZK, Yuan CQ (2022) A novel finding of tribological and mechanical linking to micro-convex texture on hydrophilic composites surface under water-lubricating conditions. Macromol Mater Eng 307(5):2100844. https://doi.org/10.1002/mame.202100844

Bostanci H, Rini DP, Kizito JP, Singh V, Seal S, Chow LC (2014) High heat flux spray cooling with ammonia: Investigation of enhanced surfaces for HTC. Int J Heat Mass Transf 75:718–725. https://doi.org/10.1016/j.ijheatmasstransfer.2014.04.019

Kwon MH, Shin HS, Chu CN (2014) Fabrication of a super-hydrophobic surface on metal using laser ablation and electrodeposition. Appl Surf Sci 288(1):222–228. https://doi.org/10.1016/j.apsusc.2013.10.011

Guo ZW, Xie X, Yuan CQ, Bai XQ (2019) Study on influence of micro convex textures on tribological performances of UHMWPE material under the water-lubricated conditions. Wear 426(1):1327–1335. https://doi.org/10.1016/j.wear.2019.01.010

Jia JL, Xu TC, Zhong L, Xu J, Zhou XY, Li SC (2022) Analysis of flow field for ECM square deep hole with two-section square cone combination cathode. Int J Adv Manuf Technol 121(7–8):5617–5634. https://doi.org/10.1007/s00170-022-09670-7

Bostanci H, Saarloos BA, Rini DP, Kizito JP, Chow LC. (2008, May). Spray cooling with ammonia on micro-structured surfaces. In 2008 11th Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronic Systems (pp. 290–295). IEEE. https://doi.org/10.1109/ITHERM.2008.4544282

Tang G, Ho JKL, Dong G, Hua M (2016) Fabrication self-recovery bulge textures on TiNi shape memory alloy and its tribological properties in lubricated sliding. Tribol Int 96(1):11–22. https://doi.org/10.1016/j.triboint.2015.12.011

Huang X, Yang W, Ming T, Shen W, Yu X (2017) Heat transfer enhancement on a microchannel heat sink with impinging jets and dimples. Int J Heat Mass Transf 112:113–124. https://doi.org/10.1016/j.ijheatmasstransfer.2017.04.078

Zhang Z, Zuo G, Gan S, Chen Z, Zhao L, Carr S. (2021). EDEM investigation and experimental evaluation of abrasive wear resistance performance of bionic micro-thorn and convex hull geometrically coupled structured surface. In 2021 ASABE Annual International Virtual Meeting (p. 1). American Society of Agricultural and Biological Engineers. https://doi.org/10.13031/aim.202101149

Dunn A, Wasley TJ, Li J, Kay RW, Stringer J, Smith PJ, Shephard JD (2016) Laser textured superhydrophobic surfaces and their applications for homogeneous spot deposition. Appl Surf Sci 365:153–159. https://doi.org/10.1016/j.apsusc.2016.01.019

He Y, Yang J, Wang H, Gu Z, Fu Y (2022) Micro-dimple and micro-bulge textures: Influence of surface topography types on stick–slip behavior under starved lubrication. Appl Surf Sci 585:152501. https://doi.org/10.1016/j.apsusc.2022.152501

Hua X, Tian Z, Xie X, Zhang P, Xu J, Zhu Y, Yin B (2020) Tribological behavior and abrasion resistance mechanism of laser micro-bulge texturing surface under full oil lubrication. Tribol Trans 63(4):726–735. https://doi.org/10.1080/10402004.2020.1738610

Liang HN, Liu ZQ, Chen DL, Song JL, Lin NM. (2022). Analysis of EDM process parameters on imprint mould surface texture. Heat Treat Metals 47(3):20–27. (In Chinese) https://doi.org/10.13251/j.issn.0254-6051.2022.03.004

Yanagishita T, Murakoshi K, Kondo T, Masuda H (2018) Preparation of superhydrophobic surfaces with micro/nano alumina molds. RSC Adv 8(66):37890–37890. https://doi.org/10.1039/C8RA07497F

Sun Y, Ling S, Zhao D, Liu J, Liu Z, Song J (2020) Through-mask electrochemical micromachining of micro pillar arrays on aluminum. Surf Coat Technol 401:126277. https://doi.org/10.1016/j.surfcoat.2020.126277

Chen P, Aso T, Sasaki R, Ashida M, Tsutsumi Y, Doi H, Hanawa T (2018) Adhesion and differentiation behaviors of mesenchymal stem cells on titanium with micrometer and nanometer-scale grid patterns produced by femtosecond laser irradiation. J Biomed Mater Res Part A 106(10):2735–2743. https://doi.org/10.1002/jbm.a.36503

Mao B, Siddaiah A, Liao Y, Menezes PL (2020) Laser surface texturing and related techniques for enhancing tribological performance of engineering materials: A review. J Manuf Process 53:153–173. https://doi.org/10.1016/j.jmapro.2020.02.009

Baroi BK, Jagadish PPK (2022) A review on sustainability, health, and safety issues of electrical discharge machining. J Braz Soc Mech Sci Eng 44(2):59. https://doi.org/10.1007/s40430-021-03351-4

Al-Sharafi A, Yilbas BS, Ali H (2017) Droplet heat transfer on micro-post arrays: Effect of droplet size on droplet thermal characteristics. Int J Heat Fluid Flow 68:62–78. https://doi.org/10.1016/j.ijheatfluidflow.2017.09.012

Frotscher O, Schaarschmidt I, Lauwers D, Paul R, Meinke M, Steinert P, Richter M (2022) Investigation of Lorentz force–induced flow of NaNO3-electrolyte for magnetic field–assisted electrochemical machining. Int J Adv Manuf Technol 121(1–2):937–947. https://doi.org/10.1007/s00170-022-09349-z

Xu L, Wang X, Zhao C (2019) Electrochemical micromachining with sinusoidal signals. J Electrochem Soc 166(10):E275. https://doi.org/10.1149/2.0081910jes

Skoczypiec S, Lipiec P, Bizoń W, Wyszyński D (2021) Selected aspects of electrochemical micromachining technology development. Materials 14(9):2248. https://doi.org/10.3390/ma14092248

Ling S, Li M, Liu Y, Wang K, Jiang Y (2020) Improving machining localization and surface roughness in wire electrochemical micromachining using a rotating ultrasonic helix electrode. Micromachines 11(7):698. https://doi.org/10.3390/mi11070698

Panda HS, Mishra K, Bhattacharyya B (2022) Anodic polarization study of step pulse waveform for machining accuracy in electrochemical micromachining. J Electrochem Soc 169(5):053504. https://doi.org/10.1149/1945-7111/ac6e8e

Xu L, Wang J, Zhao C (2021) Electrochemical micromachining using real pulse signals. J Electrochem Soc 168(8):083504. https://doi.org/10.1149/1945-7111/ac1eb9

Wang MH, Chen X, Tong WJ, Wang JJ, Wang XD (2020) Influences of gap pressure on machining performance in radial ultrasonic rolling electrochemical micromachining. Int J Adv Manuf Technol 107:157–166. https://doi.org/10.1007/s00170-020-05012-7

Wang MH, Lv M, Zhang RY, Tong WJ, Xu XF. (2023). Effect of ultrasonic cavitation micro-jet impact on corrosion of material in ultrasonic assisted electrochemical micromachining. J Appl Electrochem 1–15. https://doi.org/10.1007/s10800-023-01868-1

Funding

This project was supported by the National Natural Science Foundation of China (Grant No. 51975532) and the Zhejiang Provincial Natural Science Foundation (Grant No. LY19E050007).

Author information

Authors and Affiliations

Contributions

Minghuan Wang: paper writing, proofreading of paper content. Wenjun Liu: simulation, paper writing, data compilation, fgure production. Ming Lv: article translation and proofreading. Xin Heng, Xuefeng Xu: article typesetting and format modification.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, M., Liu, W., Heng, X. et al. Study of micro-bulges texture preparation in ultrasonic rolling pulse electrochemical micromachining. Int J Adv Manuf Technol 130, 2785–2798 (2024). https://doi.org/10.1007/s00170-023-12815-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12815-x