Abstract

Graphene merges properties such as high conductivity and outstanding mechanical performance. In tribology, it is expected to be an excellent solid lubricant at both the macro-scale and micro-scale. As a result, graphene is particularly suitable for the self-lubricating anti-wear coatings production on metal substrates. Electrodeposition is one of the most effective processes and, therefore, most widely used in industries to produce metal-graphene coatings on conductive substrates. In particular, nickel-graphene electrodeposited coatings are the most present in literature. However, the environmental impact of the galvanic bath represents a limit in the widespread use of co-deposition through electroplating. The electrophoretic deposition may be an appealing alternative despite the solvent used for the graphene dispersion requires a high resource consumption, increasing the environmental impact. This paper investigates electrophoretic deposition and electroplating through life cycle assessment and costing procedures (LCA and LCC). To this aim, different coatings were produced considering many liquid mediums and tested to achieve specified performance. Then, ANOVA, life cycle assessment, and life cycle costing were performed to assess process repeatability and performance in terms of environmental impact. Electrophoretic deposition showed excellent results compared with electroplating, obtaining a maximum wear resistance improvement of over 80% and a significant reduction in environmental impact and cost in all the scenarios.

Similar content being viewed by others

References

Novoselov KS, Geim AK, Morozov SV et al (2004) Electric field effect in atomically thin carbon films. Science 306:666–669. https://doi.org/10.1126/science.1102896

Tang Y, Yang X, Wang R, Li M (2014) Enhancement of the mechanical properties of graphene–copper composites with graphene–nickel hybrids. Mater Sci Eng A 599:247–254. https://doi.org/10.1016/J.MSEA.2014.01.061

Zhang L, Li N, Xia H et al (2016) Preparation and mechanical properties of (Ni-Fe)-graphene composite coating. Adv Eng Mater 18:1716–1719. https://doi.org/10.1002/adem.201600357

Shen B, Hong H, Chen S et al (2019) Cathodic electrophoretic deposition of magnesium nitrate modified graphene coating as a macro-scale solid lubricant. Carbon N Y 145:297–310. https://doi.org/10.1016/J.CARBON.2019.01.046

Sadeghinezhad E, Mehrali M, Saidur R et al (2016) A comprehensive review on graphene nanofluids: recent research, development and applications. Energy Convers Manag 111:466–487. https://doi.org/10.1016/J.ENCONMAN.2016.01.004

Rasheed AK, Khalid M, Rashmi W et al (2016) Graphene based nanofluids and nanolubricants – review of recent developments. Renew Sust Energ Rev 63:346–362. https://doi.org/10.1016/J.RSER.2016.04.072

Saurín N, Sanes J, Bermúdez MD (2016) New graphene/ionic liquid nanolubricants. Mater Today Proc 3:S227–S232. https://doi.org/10.1016/J.MATPR.2016.02.038

Gusain R, Mungse HP, Kumar N et al (2016) Covalently attached graphene–ionic liquid hybrid nanomaterials: synthesis, characterization and tribological application. J Mater Chem A Mater 4:926–937. https://doi.org/10.1039/C5TA08640J

Bandeira P, Monteiro J, Baptista AM, Magalhães FD (2016) Influence of oxidized graphene nanoplatelets and [DMIM][NTf2] ionic liquid on the tribological performance of an epoxy-PTFE coating. Tribol Int 97:478–489. https://doi.org/10.1016/J.TRIBOINT.2016.02.005

Zhao J, He Y, Wang Y et al (2016) An investigation on the tribological properties of multilayer graphene and MoS2 nanosheets as additives used in hydraulic applications. Tribol Int 97:14–20. https://doi.org/10.1016/J.TRIBOINT.2015.12.006

Ramón-Raygoza ED, Rivera-Solorio CI, Giménez-Torres E et al (2016) Development of nanolubricant based on impregnated multilayer graphene for automotive applications: analysis of tribological properties. Powder Technol 302:363–371. https://doi.org/10.1016/J.POWTEC.2016.08.072

Blanco D, González R, Viesca JL et al (2017) Antifriction and antiwear properties of an ionic liquid with fluorine-containing anion used as lubricant additive. Tribol Lett 65:66. https://doi.org/10.1007/s11249-017-0846-4

Góral A, Lityńska-Dobrzyńska L, Kot M (2017) Effect of surface roughness and structure features on tribological properties of electrodeposited nanocrystalline Ni and Ni/Al2O3 coatings. J Mater Eng Perform 26:2118–2128. https://doi.org/10.1007/s11665-017-2662-2

Ren Z, Meng N, Shehzad K et al (2015) Mechanical properties of nickel-graphene composites synthesized by electrochemical deposition. Nanotechnology 26:065706. https://doi.org/10.1088/0957-4484/26/6/065706

Allahyarzadeh MH, Aliofkhazraei M, Rezvanian AR et al (2016) Ni-W electrodeposited coatings: characterization, properties and applications. Surf Coat Technol 307:978–1010. https://doi.org/10.1016/J.SURFCOAT.2016.09.052

Ibáñez A, Escudero-Cid R, Ocón P, Fatás E (2012) Effect of the pulse plating parameters on the mechanical properties of nickel electrodeposits. Surf Coat Technol 212:94–100. https://doi.org/10.1016/J.SURFCOAT.2012.09.027

Luo JK, Pritschow M, Flewitt AJ et al (2006) Effects of process conditions on properties of electroplated Ni thin films for microsystem applications. J Electrochem Soc 153:D155. https://doi.org/10.1149/1.2223302

Shao W, Nabb D, Renevier N et al (2012) Mechanical and anti-corrosion properties of TiO 2 nanoparticle reinforced ni coating by electrodeposition. J Electrochem Soc 159:D671–D676. https://doi.org/10.1149/2.065211jes

Chung CK, Chang WT (2007) Effect of pulse frequency on the morphology and nanoindentation property of electroplated nickel films. Microsyst Technol 13:537–541. https://doi.org/10.1007/s00542-006-0194-z

Guglielmi N (1972) Kinetics of the deposition of inert particles from electrolytic baths. J Electrochem Soc 119:1009. https://doi.org/10.1149/1.2404383

Szeptycka B, Gajewska-Midzialek A (2015) Nickel-graphene composite coatings. Composite Theory and Practice 15:107–111

Chen J, Li J, Xiong D et al (2016) Preparation and tribological behavior of Ni-graphene composite coating under room temperature. Appl Surf Sci 361:49–56. https://doi.org/10.1016/j.apsusc.2015.11.094

Chavez-Valdez A, Shaffer MSP, Boccaccini AR (2013) Applications of graphene electrophoretic deposition. A review. J Phys Chem B 117:1502–1515. https://doi.org/10.1021/jp3064917

Sheng K, Sun Y, Li C et al (2012) Ultrahigh-rate supercapacitors based on eletrochemically reduced graphene oxide for ac line-filtering. Sci Rep 2:247. https://doi.org/10.1038/srep00247

Kim S, Oh J-S, Kim M-G et al (2014) Electromagnetic interference (EMI) transparent shielding of reduced graphene oxide (RGO) interleaved structure fabricated by electrophoretic deposition. ACS Appl Mater Interfaces 6:17647–17653. https://doi.org/10.1021/am503893v

Quezada-Rentería JA, Cházaro-Ruiz LF, Rangel-Mendez JR (2017) Synthesis of reduced graphene oxide (rGO) films onto carbon steel by cathodic electrophoretic deposition: anticorrosive coating. Carbon N Y 122:266–275. https://doi.org/10.1016/J.CARBON.2017.06.074

Maaoui H, Singh SK, Teodorescu F et al (2017) Copper oxide supported on three-dimensional ammonia-doped porous reduced graphene oxide prepared through electrophoretic deposition for non-enzymatic glucose sensing. Electrochim Acta 224:346–354. https://doi.org/10.1016/J.ELECTACTA.2016.12.078

Liu X, Qian T, Xu N et al (2015) Preparation of on chip, flexible supercapacitor with high performance based on electrophoretic deposition of reduced graphene oxide/polypyrrole composites. Carbon N Y 92:348–353. https://doi.org/10.1016/J.CARBON.2015.05.039

An SJ, Zhu Y, Lee SH et al (2010) Thin film fabrication and simultaneous anodic reduction of deposited graphene oxide platelets by electrophoretic deposition. J Phys Chem Lett 1:1259–1263. https://doi.org/10.1021/jz100080c

Marcin Behunová D, Gallios G, Girman V et al (2021) Electrophoretic deposition of graphene oxide on stainless steel substrate. Nanomaterials 11:1779. https://doi.org/10.3390/nano11071779

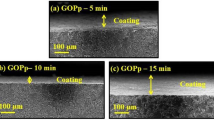

Mallick M, N A (2022) Effects of electrophoretic deposited graphene coating thickness on the corrosion and wear behaviors of commercially pure titanium. Surf Coat Technol 450:128946. https://doi.org/10.1016/J.SURFCOAT.2022.128946

Liu Y, Li J, Chen X, Luo J (2019) Fluorinated graphene: a promising macroscale solid lubricant under various environments. ACS Appl Mater Interfaces 11:40470–40480. https://doi.org/10.1021/acsami.9b13060

Chen S, Hong H, Shen B (2022) Substrate-dependent enhancement of the durability of EPD graphene coating as a macroscale solid lubricant. Surf Interface Anal 54:978–985. https://doi.org/10.1002/sia.7123

Baiocco G, Genna S, Salvi D, Ucciardello N (2023) Laser texturing to increase the wear resistance of an electrophoretic graphene coating on copper substrates. Materials 16:5359. https://doi.org/10.3390/ma16155359

Ma Y, Han J, Wang M et al (2018) Electrophoretic deposition of graphene-based materials: a review of materials and their applications. J Mater 4:108–120. https://doi.org/10.1016/J.JMAT.2018.02.004

Curran MA (2013) Life cycle assessment: a review of the methodology and its application to sustainability. Curr Opin Chem Eng 2:273–277. https://doi.org/10.1016/J.COCHE.2013.02.002

Garbin M, Zortea RB, Moraes CAM et al (2023) Environmental assessment of the automotive cage’s production process by life cycle assessment methodology. Int J Adv Manuf Technol 128:4685–4701. https://doi.org/10.1007/s00170-023-12267-3

Firmino AS, Akim EK, de Oliveira JA, Silva DAL (2022) Green machining of aluminum pipes: an integrated approach for eco-efficiency and life cycle assessment in manufacturing systems. Int J Adv Manuf Technol 121:6225–6241. https://doi.org/10.1007/s00170-022-09737-5

Marconi M, Pietroni G, Rubino G (2022) Comparing the environmental and economic performances of different substrate pre-treatment processes for diamond coating deposition. Procedia CIRP 105:476–481. https://doi.org/10.1016/j.procir.2022.02.079

Rubino G, Marconi M, Baiocco G, Menna E (2022) Technical, environmental, and economic feasibility investigation of an innovative dry washing process for metal degreasing. Int J Adv Manuf Technol 121:7475–7492. https://doi.org/10.1007/s00170-022-09819-4

Guarino S, Ponticelli GS, Tagliaferri F, Venettacci S (2020) Life cycle analysis of an innovative fluidized bed degreasing process. J Clean Prod 245:118947. https://doi.org/10.1016/J.JCLEPRO.2019.118947

Venettacci S, Ponticelli GS, Guarino S (2021) Fluidised bed finishing process for aeronautical applications: environmental and technical-economic assessment. J Clean Prod 299:126900. https://doi.org/10.1016/J.JCLEPRO.2021.126900

Vita A, Castorani V, Germani M, Marconi M (2019) Comparative life cycle assessment and cost analysis of autoclave and pressure bag molding for producing CFRP components. Int J Adv Manuf Technol 105:1967–1982. https://doi.org/10.1007/s00170-019-04384-9

Cucinotta F, Guglielmino E, Sfravara F (2017) Life cycle assessment in yacht industry: a case study of comparison between hand lay-up and vacuum infusion. J Clean Prod 142:3822–3833. https://doi.org/10.1016/J.JCLEPRO.2016.10.080

Moign A, Vardelle A, Legoux JG, Themelis NJ (2009) LCA comparison of electroplating and other thermal spray processes. In: Marple BR, Hyland MM, Lau Y-C, et al (eds). pp 1207–1212. https://doi.org/10.1361/cp2009itsc1207

Guarino S, Ucciardello N, Venettacci S, Genna S (2017) Life cycle assessment of a new graphene-based electrodeposition process on copper components. J Clean Prod 165:520–529. https://doi.org/10.1016/J.JCLEPRO.2017.07.168

Kalyankar V, Bhoskar A, Deshmukh D, Patil S (2022) On the performance of metallurgical behaviour of Stellite 6 cladding deposited on SS316L substrate with PTAW process. Can Metall Q 61:130–144. https://doi.org/10.1080/00084433.2022.2031681

Bhoskar A, Kalyankar V, Deshmukh D (2023) Metallurgical characterisation of multi-track Stellite 6 coating on SS316L substrate. Can Metall Q 62:665–677. https://doi.org/10.1080/00084433.2022.2149009

Kalyankar V, Bhoskar A (2021) Influence of torch oscillation on the microstructure of Colmonoy 6 overlay deposition on SS304 substrate with PTA welding process. Metall Res Technol 118:406. https://doi.org/10.1051/metal/2021045

Lin J, Li J, Liu T et al (2021) Evaluation of friction reduction and frictionless stress in ultrasonic vibration forming process. J Mater Process Technol 288:116881. https://doi.org/10.1016/j.jmatprotec.2020.116881

Yang C, Shan X, Xie T (2016) Titanium wire drawing with longitudinal-torsional composite ultrasonic vibration. Int J Adv Manuf Technol 83:645–655. https://doi.org/10.1007/s00170-015-7540-1

Molaie MM, Akbari J, Movahhedy MR (2016) Ultrasonic assisted grinding process with minimum quantity lubrication using oil-based nanofluids. J Clean Prod 129:212–222. https://doi.org/10.1016/j.jclepro.2016.04.080

Amini S, Soleimani M, Paktinat H, Lotfi M (2017) Effect of longitudinal−torsional vibration in ultrasonic-assisted drilling. Mater Manuf Process 32:616–622. https://doi.org/10.1080/10426914.2016.1198027

Jamshidi H, Nategh MJ (2013) Theoretical and experimental investigation of the frictional behavior of the tool–chip interface in ultrasonic-vibration assisted turning. Int J Mach Tools Manuf 65:1–7. https://doi.org/10.1016/j.ijmachtools.2012.09.004

Jolliet O, Margni M, Charles R et al (2003) IMPACT 2002+: a new life cycle impact assessment methodology. Int J Life Cycle Assess 8:324. https://doi.org/10.1007/BF02978505

Baiocco G, Menna E, Rubino G, Ucciardello N (2022) Mechanical characterization of functional Cu-GnP composite coatings for lubricant applications. Surf Eng 38:72–78. https://doi.org/10.1080/02670844.2022.2040187

O’Neill A, Khan U, Nirmalraj PN et al (2011) Graphene dispersion and exfoliation in low boiling point solvents. J Phys Chem C 115:5422–5428. https://doi.org/10.1021/jp110942e

Konios D, Stylianakis MM, Stratakis E, Kymakis E (2014) Dispersion behaviour of graphene oxide and reduced graphene oxide. J Colloid Interface Sci 430:108–112. https://doi.org/10.1016/J.JCIS.2014.05.033

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Baiocco, G., Salvi, D. & Ucciardello, N. Sustainable coating solutions: a comparative life cycle analysis of electrophoretic deposition and electroplating for graphene-reinforced anti-wear coatings. Int J Adv Manuf Technol 130, 3341–3354 (2024). https://doi.org/10.1007/s00170-023-12796-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12796-x