Abstract

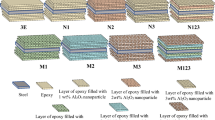

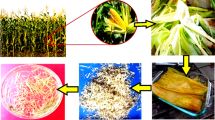

The distribution of nanoparticles in the production of epoxy coating results in particle clustering and agglomeration. In this work, biosynthesis of silver nanoparticles was used to modify maize cob ash nanoparticles to avoid particle clusters. The stir-air spray method was to developed composite coating of 0, 2, 4, 6, 8, and 10 wt% nano-maize cob ash modified with 0.5 wt% AgNPs. The microstructure, adhesion strength, wear, and thermal behavior of the coating were investigated. Optimal properties were obtained at 0.5 wt% silver nanoparticles modified with 8 wt% nano-maize cob ash with 84.26% thermal properties, higher wear resistance, a lower coefficient of friction with deep cuts, less plastic deformation, and fewer wear grooves. It is established that low-cost biosynthesis of silver nanoparticles can be used to improve the distribution of nano-maize cob ash for the polymer coating of mild steel.

Similar content being viewed by others

Data availability

The authors confirm that the data supporting this study’s conclusions is included in the publication.

References

Kalendova A (2003) Effects of particle sizes and shapes of zinc metal on the properties of anticorrosive coatings. Prog Org Coat 46:324–332

Shittu MD, Olawale JO, Adeoye MO, Oluwasegun KM, Adebayo KM, Ige OO (2014) Investigation of corrosion resistance of polystyrene as an inhibitor in hydrochloric and tetra-oxo sulphate VI acids. Int J Mater Chem 4(1):9–13. https://doi.org/10.5923/j.ijmc.20140401.02

Talo A, Forsén O, Yläsaar S (1999) Corrosion protective polyaniline epoxy blend coatings on mild steel. Synth Met 102(1):1394–1395

Ahmed AA, Al-Dulaimi SH, Khan MI (2011) Corrosion protection of carbon steel using polyaniline composite with aluminium oxide. Pertanika J Sci Technol 19(2):329–337

Shi X, Nguyen TA, Suo Z, Liu Y, Avci R (2009) Effect of nanoparticles on the anticorrosion and mechanical properties of epoxy coating. Surf Coat Technol 204(3):237–245. https://doi.org/10.1016/j.surfcoat.2009.06.04

Ananda Kumar S, Shree Meenakshi K, Sankaranarayanan TSN, Srikanth S (2008) Corrosion resistant behaviour of PANI–metal bilayer coatings. Prog Org Coat 62(3):285–292. https://doi.org/10.1016/j.porgcoat.2008.01.00

Yu HJ, Wang L, Shi Q, Jiang GH, Zhao ZR, Dong XC (2006) Study on nano-CaCO3 modified epoxy powder coatings. Prog Org Coat 55(3):296–300. https://doi.org/10.1016/j.porgcoat.2006.01.00

Behzadnasab M, Mirabedini SM, Kabiri K, Jamali S (2011) Corrosion performance of epoxy coatings containing silane treated ZrO2 nanoparticles on mild steel in 3.5% NaCl solution. Corros Sci 53(1):89–98. https://doi.org/10.1016/j.corsci.2010.09.026

Valipour P, Ghasemi SE, Khosravani MR, Ganji DD (2016) Theoretical analysis on nonlinear vibration of fluid flow in single-walled carbon nanotube. J Theor Appl Phys 10(3):211–218. https://doi.org/10.1007/s40094-016-0217-9

Yang L, Ji W, Zhang Z, Jin X (2019) Thermal conductivity enhancement of water by adding graphene nano-sheets: consideration of particle loading and temperature effects. Int Commun Heat Mass Transfer 109:104353. https://doi.org/10.1016/j.icheatmasstransfer

Samardžija M, Stojanovi´c I, Vukovi´cDomanovac M, Alar V (2023) Epoxy coating modification with metal nanoparticles to improve the anticorrosion, migration, and antibacterial properties. Coatings 13:1201. https://doi.org/10.3390/coatings13071201

Brostow W, Dutta M, Rusek P (2010) Modified epoxy coatings on mild steel: tribology and surface energy. Eur Polymer J 46(11):2181–2189. https://doi.org/10.1016/j.eurpolymj.2010.08.0

Yang W, Feng W, Liao Z, Yang Y, Miao G, Yu B, Pei X (2021) Protection of mild steel with molecular engineered epoxy nanocomposite coatings containing corrosion inhibitor functionalized nanoparticles. Surf Coat Technol 406(126639):0257–8972. https://doi.org/10.1016/j.surfcoat.2020.126639

Wu J, Ji G, Wu Q (2022) Preparation of epoxy/ZrO2 composite coating on the Q235 surface by electrostatic spraying and its corrosion resistance in 3.5% NaCl solution. RSC Adv 12:10625

Aigbodion VS (2020) Morphological and electrochemical behavior of epoxy–activated orange juice functionalized rice husk nanoparticles composite coating on mild steel. Chem Data Collect 29(100526):2405–8300. https://doi.org/10.1016/j.cdc.2020.100526

Aigbodion VS, Ozor PA (2023) New insights into the polymer coating of mild steel using activated orange juice functionalized rice husk nanoparticles. In: Kohl H, Seliger G, Dietrich F (eds) Manufacturing Driving Circular Economy. GCSM 2022. Lecture Notes in Mechanical Engineering. Springer, Cham, 1037–1043. https://doi.org/10.1007/978-3-031-28839-5_115

Choi JY, Nam J, Yun BY, Kim YU, Kim S (2022) Utilization of corn cob, an essential agricultural residue difficult to disposal: composite board manufactured improved thermal performance using microencapsulated PCM. Ind Crops Prod 183:114931. https://doi.org/10.1016/j.indcrop.2022.114931

Aigbodion VS (2020) Explicit simultaneous enhancement of adhesion strength and wear resistance of functional value-added epoxy-functionalized rice husk ash nanoparticle composite coating. Int J Adv Manuf Technol 109:2205–2214. https://doi.org/10.1007/s00170-020-05758-0

Aigbodion VS (2021) Explicit microstructure and electrical conductivity of epoxy/carbon nanotube and green silver nanoparticle enhanced hybrid dielectric composites. Nanocomposites 7(1):35–43. https://doi.org/10.1080/20550324.2020.1868690

Tuaweri TJ, Jombo PP, Okpala AN (2014) Corrosion resistance characteristics Of Zn-Ni/SiO2 composite coatings. Int J Adv Mater Sci Eng (IJAMSE) 3(2):123

Mohammad RK, Anders D, Reinicke T (2023) Effects of post-processing on the fracture behavior of surface-treated 3D-printed parts. CIRP J Manuf Sci Technol 46:148–156. https://doi.org/10.1016/j.cirpj.2023.08.006

Kumar SA, Bhandari H, Sharma C, Khatoon F, Dhawan SK (2012) A new smart coating of polyaniline-SiO2composite for protection of mild steel against corrosion in strong acidic medium. Polym Int 62(8):1192–1201. https://doi.org/10.1002/pi.4406

Lyu Q, Lu S (2023) P1. Construction of surface HA/TiO2 coating on porous titanium cages produced by 3D printing and the study of its efficacy in promoting the spinal fusion in a goat model. Spine J 23(9):S109. https://doi.org/10.1016/j.spinee.2023.06.226

Mohammad Reza Khosravani (2023) Denis Anders, Tamara Reinicke, Effects of post-processing on the fracture behavior of surface-treated 3D-printed parts. CIRP J Manuf Sci Technol 46:148–156. https://doi.org/10.1016/j.cirpj.2023.08.006

Xavier JR (2020) Electrochemical, mechanical and adhesive properties of surface modified NiO-epoxy nanocomposite coatings on mild steel. Mater Sci Eng B 260:114639. https://doi.org/10.1016/j.mseb.2020.114639

Acknowledgements

The authors acknowledge the financial support through Researchers Supporting Project number (RSPD2023R768), King Saud University, Riyadh, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

All contributed 100% to the study’s development, from experimentation to analysis.

Corresponding author

Ethics declarations

Ethics approval

Because this experiment does not involve people or animals, no ethics committee approval is required.

Consent to participate

Because this study does not include people or animals, no permission is required to participate.

Consent for publication

The authors give the publisher the consent to publish the work.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ezzat, A.O., Aigbodion, V.S. & Ohiemi, I.E. Multifaceted incorporation of epoxy/functionalized maize cob nanoparticle with biosynthesis silver nanoparticles for composite coating of mild steel. Int J Adv Manuf Technol 130, 1465–1476 (2024). https://doi.org/10.1007/s00170-023-12793-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12793-0