Abstract

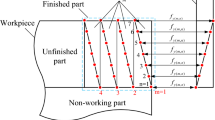

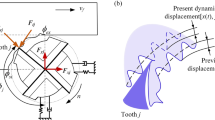

Regenerative chatter is a common challenge in milling large and difficult-to-cut complex curved parts, which seriously affects the machining efficiency and quality. Variable pitch cutters (VPCs) and process damping are known to be effective in suppressing chatter. However, the complex multiple interactions between process damping and variable pitch bull-nose cutters (VPBNCs) have been rarely investigated due to unavoidable runout and multiple modes of the milling system. In addition, the simultaneous identification of shearing force coefficients and ploughing force coefficients presents a challenge when the dynamic characteristics of VPCs are considered. To this end, this paper first establishes the geometric parametric modeling of VPBNCs, and a mechanical model is proposed to uniformly handle shearing force and process damping force, which accounts for cutter runout. Secondly, the multiple interactions comprehensive dynamics model of VPBNCs milling system is developed. The milling system involves multiple regeneration delays, multiple modes and process damping effects. A modified hybrid multi-step method (MHMSM) is employed to analyze milling stability. Then, combined with the mechanical model considering cutter vibration, a multi-parameter synchronous calibration method (MPSCM) is proposed to identify ploughing force coefficients and runout parameters. Finally, experimental validation is performed to verify the proposed model and calibration method. The results show good agreement between simulation and experimental results. Furthermore, the joint influences of process damping and pitch angle variation on stability in different speed ranges are explored in detail.

Similar content being viewed by others

Data availability

Data and materials used in this research are available.

References

Altintas Y, Weck M (2004) Chatter stability of metal cutting and grinding. CIRP Ann 53(2):619–642. https://doi.org/10.1016/S0007-8506(07)60032-8

Sun Y, Zheng M, Jiang SL, Zhan DN, Wang RQ (2023) A state-of-the-art review on chatter stability in machining thin-walled parts. Machines 11(3):359. https://doi.org/10.3390/machines11030359

Yan SC, Sui L, Wang SQ, Sun YW (2023) On-line tool wear monitoring under variable milling conditions based on a condition-adaptive hidden semi-markov model (CAHSMM). Mech Syst Signal Process 200:110644. https://doi.org/10.1016/j.ymssp.2023.110644

Altintas Y, Stepan G, Budak E, Schmitz T, Kilic ZM (2020) Chatter stability of machining operations. J Manuf Sci Eng 142(11):110801. https://doi.org/10.1115/1.4047391

Sun YW, Jiang SL (2018) Predictive modeling of chatter stability considering force-induced deformation effect in milling thin-walled parts. Int J Mach Tools Manuf 135:38–52. https://doi.org/10.1016/j.ijmachtools.2018.08.003

Eksioglu C, Kilic ZM, Altintas Y (2012) Discrete-time prediction of chatter stability, cutting forces, and surface location errors in flexible milling systems. J Manuf Sci Eng 134(6):061006. https://doi.org/10.1115/1.4007622

Munoa J, Beudaert X, Dombovari Z, Altintas Y, Budak E, Brecher C, Stepan G (2016) Chatter suppression techniques in metal cutting. CIRP Ann 65(2):785–808. https://doi.org/10.1016/j.cirp.2016.06.004

Quintana G, Ciurana J (2011) Chatter in machining processes: a review. Int J Mach Tools Manuf 51(5):363–376. https://doi.org/10.1016/j.ijmachtools.2011.01.001

Defant F, Ghezzi D, Albertelli P (2023) Development of a generalized extended harmonic solution for analyzing the combination of chatter suppression techniques in milling. J Sound Vib 543:117368. https://doi.org/10.1016/j.jsv.2022.117368

Altintaş Y, Budak E (1995) Analytical prediction of stability lobes in milling. CIRP Ann 44(1):357–362. https://doi.org/10.1016/S0007-8506(07)62342-7

Insperger T, Muñoa J, Zatarain M, Peigné G (2006) Unstable islands in the stability chart of milling processes due to the helix angle. In: CIRP 2nd international conference on high performance cutting. Vancouver, Canada, pp 12–13

Park SS, Qin YM (2007) Robust regenerative chatter stability in machine tools. Int J Adv Manuf Technol 33:389–402. https://doi.org/10.1007/s00170-006-0778-x

Graham E, Mehrpouya M, Park SS (2013) Robust prediction of chatter stability in milling based on the analytical chatter stability. J Manuf Process 15(4):508–517. https://doi.org/10.1016/j.jmapro.2013.08.005

Hahn RS (2022) Metal-cutting chatter and its elimination. Trans Am Soc Mech Eng 75(6):1073–1078. https://doi.org/10.1115/1.4015526

SLAVic-EK J (1965) The effect of irregular tooth pitch on stability of milling. Proc 6th MTDR Conf. Praguc, Czcchoslovakia, pp 19–22

Altintas Y, Engin S, Budak E (1999) Analytical stability prediction and design of variable pitch cutters. Int J Mech Sci 121:173–178. https://doi.org/10.1115/1.2831201

Budak E, Altintas Y (1998) Analytical prediction of chatter stability in milling—part I: general formulation. J Dyn Syst Meas Control 120(1):22–30. https://doi.org/10.1115/1.2801317

Turner S, Merdol D, Altintas Y, Ridgway K (2007) Modelling of the stability of variable helix end mills. Int J Mach Tools Manuf 47(9):1410–1416. https://doi.org/10.1016/j.ijmachtools.2006.08.028

Comak A, Budak E (2017) Modeling dynamics and stability of variable pitch and helix milling tools for development of a design method to maximize chatter stability. Precis Eng 47:459–468. https://doi.org/10.1016/j.precisioneng.2016.09.021

Stepan G, Hajdu D, Iglesias A, Takacs D (2018) Ultimate capability of variable pitch milling cutters. CIRP Ann 67(1):373–376. https://doi.org/10.1016/j.cirp.2018.03.005

Zhan DN, Jiang SL, Niu JB, Sun YW (2020) Dynamics modeling and stability analysis of five-axis ball-end milling system with variable pitch tools. Int J Mech Sci 182:105774. https://doi.org/10.1016/j.ijmecsci.2020.105774

Zhan DN, Li SK, Jiang SL, Sun YW (2022) Optimal pitch angles determination of ball-end cutter for improving five-axis milling stability. J Manuf Process 84:832–846. https://doi.org/10.1016/j.jmapro.2022.10.024

Tunç LT, Budak E (2012) Effect of cutting conditions and tool geometry on process damping in machining. Int J Mach Tools Manuf 57:10–19. https://doi.org/10.1016/j.ijmachtools.2012.01.009

Feng J, Wan M, Dong ZY, Zhang WH (2019) A unified process damping model considering the varying stiffness of the milling system. Int J Mach Tools Manuf 147:103470. https://doi.org/10.1016/j.ijmachtools.2019.103470

Wu DW (1988) Application of a comprehensive dynamic cutting force model to orthogonal wave-generating processes. Int J Mech Sci 30(8):581–600. https://doi.org/10.1016/0020-7403(88)90101-4

Ahmadi K, Ismail F (2010) Experimental investigation of process damping nonlinearity in machining chatter. Int J Mach Tools Manuf 50(11):1006–1014. https://doi.org/10.1016/j.ijmachtools.2010.07.002

Li ZY, Sun YW, Guo DM (2017) Chatter prediction utilizing stability lobes with process damping in finish milling of titanium alloy thin-walled workpiece. Int J Adv Manuf Technol 89:2663–2674. https://doi.org/10.1007/s00170-016-9834-3

Wang DQ, Löser M, Ihlenfeldt S, Wang XB, Liu ZB (2019) Milling stability analysis with considering process damping and mode shapes of in-process thin-walled workpiece. Int J Mech Sci 159:382–397. https://doi.org/10.1016/j.ijmecsci.2019.06.005

Tuysuz O, Altintas Y (2019) Analytical modeling of process damping in machining. J Manuf Sci Eng 141(6):061006. https://doi.org/10.1115/1.4043310

Ji YJ, Wang XB, Liu ZB, Wang HJ, Wang KJ, Wang DQ (2019) Stability prediction of five-axis ball-end finishing milling by considering multiple interaction effects between the tool and workpiece. Mech Syst Signal Process 131:261–287. https://doi.org/10.1016/j.ymssp.2019.05.058

Xin SH, Peng FY, Tang XW, Yan R, Li ZP, Wu JW (2022) Research on the influence of robot structural mode on regenerative chatter in milling and analysis of stability boundary improvement domain. Int J Mach Tools Manuf 179:103918. https://doi.org/10.1016/j.ijmachtools.2022.103918

Ozkirimli O, Tunc LT, Budak E (2016) Generalized model for dynamics and stability of multi-axis milling with complex tool geometries. J Mater Process Technol 238:446–458. https://doi.org/10.1016/j.jmatprotec.2016.07.020

Li MY, Zhao W, Li L, He N, Jamil M (2022) Chatter suppression during milling of ti-6Al-4V based on variable pitch tool and process damping effect. Machines 10(4):222. https://doi.org/10.3390/machines10040222

Otto A, Rauh S, Ihlenfeldt S, Radons G (2017) Stability of milling with non-uniform pitch and variable helix tools. Int J Adv Manuf Technol 89:2613–2625. https://doi.org/10.1007/s00170-016-9762-2

Niu JB, Ding Y, Zhu LM, Ding H (2017) Mechanics and multi-regenerative stability of variable pitch and variable helix milling tools considering runout. Int J Mach Tools Manuf 123:129–145. https://doi.org/10.1016/j.ijmachtools.2017.08.006

Jiang SL, Zhan DN, Liu Y, Sun YW, Xu JT (2022) Modeling of variable-pitch/helix milling system considering axially varying dynamics with cutter runout offset and tilt effects. Mech Syst Signal Process 168:108674. https://doi.org/10.1016/j.ymssp.2021.108674

Tunc LT, Mohammadi Y, Budak E (2018) Destabilizing effect of low frequency modes on process damped stability of multi-mode milling systems. Mech Syst Signal Process 111:423–441. https://doi.org/10.1016/j.ymssp.2018.03.051

Tyler CT, Troutman JR, Schmitz TL (2016) A coupled dynamics, multiple degree of freedom process damping model, part 2: milling. Precis Eng 46:73–80. https://doi.org/10.1016/j.precisioneng.2016.03.018

Pawade RS, Sonawane HA, Joshi SS (2009) An analytical model to predict specific shear energy in high-speed turning of inconel 718. Int J Mach Tools Manuf 49(12–13):979–990. https://doi.org/10.1016/j.ijmachtools.2009.06.007

Ducobu F, Rivière-Lorphèvre E, Filippi E (2014) Numerical contribution to the comprehension of saw-toothed Ti6Al4V chip formation in orthogonal cutting. Int J Mech Sci 81:77–87. https://doi.org/10.1016/j.ijmecsci.2014.02.017

Jomaa W, Mechri O, Lévesque J, Songmene V, Bocher P, Gakwaya A (2017) Finite element simulation and analysis of serrated chip formation during high–speed machining of AA7075–t651 alloy. J Manuf Process 26:446–458. https://doi.org/10.1016/j.jmapro.2017.02.015

Altintas Y (2012) Manufacturing automation: metal cutting mechanics, machine tool vibrations, and CNC design, 2nd edn. Cambridge, New York

Wan M, Zhang WH, Dang JW, Yang Y (2009) New procedures for calibration of instantaneous cutting force coefficients and cutter runout parameters in peripheral milling. Int J Mach Tools Manuf 49(14):1144–1151. https://doi.org/10.1016/j.ijmachtools.2009.08.005

Budak E, Tunc LT (2009) A new method for identification and modeling of process damping in machining. J Manuf Sci Eng 131(5):051019. https://doi.org/10.1115/1.4000170

Jin XL, Altintas Y (2013) Chatter stability model of micro-milling with process damping. J Manuf Sci Eng 135(3):031011. https://doi.org/10.1115/1.4024038

Ahmadi K, Altintas Y (2014) Identification of machining process damping using output-only modal analysis. J Manuf Sci Eng 136(5):051017. https://doi.org/10.1115/1.4027676

Tang XW, Peng F, Yan R, Zhu ZR, Li ZP, Xin SH (2021) Nonlinear process damping identification using finite amplitude stability and the influence analysis on five-axis milling stability. Int J Mech Sci 190:106008. https://doi.org/10.1016/j.ijmecsci.2020.106008

Wan M, Ma YC, Feng J, Zhang WH (2016) Study of static and dynamic ploughing mechanisms by establishing generalized model with static milling forces. Int J Mech Sci 114:120–131. https://doi.org/10.1016/j.ijmecsci.2016.05.010

Ahmadi K, Ismail F (2012) Stability lobes in milling including process damping and utilizing multi-frequency and semi-discretization methods. Int J Mach Tools Manuf 54–55:46–54. https://doi.org/10.1016/j.ijmachtools.2011.11.007

Huang CY, Wang JJJ (2006) Mechanistic modeling of process damping in peripheral milling. J Manuf Sci Eng 129(1):12–20. https://doi.org/10.1115/1.2335857

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. U22A20202 and No.52205516) and the China Postdoctoral Science Foundation(Grant No. 2022M720641).

Author information

Authors and Affiliations

Contributions

Methodology, investigation, software, writing—original draft: SL; methodology, writing—review and editing: DZ; investigation, writing—review and editing: SS; methodology, writing—review, supervision: YS.

Corresponding author

Ethics declarations

Ethical approval

This work does not contain any studies with human participants or animals performed by any of the authors.

Consent to participate

Not applicable.

Consent for publication

All authors have read and agreed to the published version of the manuscript.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

1.1 Detailed derivations of Eq. (62)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, S., Zhan, D., Sun, S. et al. Dynamics modeling and simultaneous identification of force coefficients for variable pitch bull-nose cutter milling considering process damping and cutter runout. Int J Adv Manuf Technol 130, 2877–2898 (2024). https://doi.org/10.1007/s00170-023-12777-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12777-0