Abstract

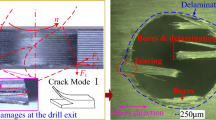

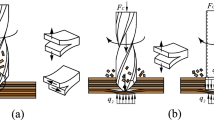

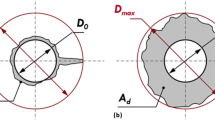

Although carbon fiber reinforced polymer (CFRP) has been widely used in various applications, it is still regarded as a kind of difficult-to-cut material due to its vulnerability to machining damages. In the current research, CFRP drilling experiments were conducted, and the matrix cracks and delamination were observed not only at the entrance and exit of holes, but also in the middle area of the holes. Therefore, it is necessary to study the distribution of these damages due to the severe effect on the mechanical properties of CFRP. In this paper, the distribution of these damages as well as their monitoring methods were investigated. First, four factors were introduced to locate the distribution of these damages that were observed by X-ray CT scanner. Then, statistical process control (SPC) was applied for damage detection with features optimized sensitivity analysis. Finally, the performance of SPC was validated, which has a high damage identifying accuracy of 86.78% and recommended for the on-line application.

Similar content being viewed by others

References

Geier N, Davim JP, Szalay T (2019) Advanced cutting tools and technologies for drilling carbon fibre reinforced polymer (CFRP) composites: a review. Compos Part A Appl Sci Manuf 125:105552. https://doi.org/10.1016/j.compositesa.2019.105552

Vigneshwaran S, Uthayakumar M, Arumugaprabu V (2018) Review on machinability of fiber reinforced polymers: a drilling approach. Silicon 10:2295–2305. https://doi.org/10.1007/s12633-018-9764-9

Wang F, Zhao M, Fu R, Liu X, Qiu S, Yan J, Zhang B (2022) Replaceable drill bit with compound step and sawtooth structures for damages and drilling-cost reduction of CFRP composite. J Manuf Process 81:1018–1027. https://doi.org/10.1016/j.jmapro.2022.07.001

Hocheng Hong (2011) Machining technology for composite materials[M]. Elsevier

Sheikh-Ahmad JY (2009) Machining of polymer composites[M]. Springer, New York

Qiu X, Li P, Tang LY, Li C, Niu Q, Li S, Tang S, Tae JK (2022) Determination of the optimal feed rate for step drill bit drilling CFRP pipe based on exit damage analysis. J Manuf Process 83:246–256. https://doi.org/10.1016/j.jmapro.2022.09.002

Yan C, Qian N, Chen Y, Wang Y, Guo N, Lin H (2022) Theoretical and experimental analyses of dynamic deformation in low-frequency vibration-assisted drilling of CFRP/Ti stacks. J Manuf Process 82:818–828. https://doi.org/10.1016/j.jmapro.2022.08.038

Liu H, Cherif M, Calamaz M, Birembaux H, Rossi F, Poulachon G, Ayed Y (2023) Progressive damage induced degradation of mechanical properties in the hole surfaces during drilling processes of CFRP. CIRP Ann 00:4–7. https://doi.org/10.1016/j.cirp.2023.04.044

Li S, Teng H, Dai L, Zhou YC, Li CP, Li PN (2023) Comprehensive prediction model of drilling temperature of UD-CFRP laminates considering the combined action of main cutting edge and chisel edge. Compos Struct 313:116899. https://doi.org/10.1016/j.compstruct.2023.116899

Ahn JH, Kim G, Min BK (2023) Exit delamination at the material interface in drilling of CFRP/metal stack. J Manuf Process 85:227–235. https://doi.org/10.1016/j.jmapro.2022.11.058

Sardiñas RQ, Reis P, Davim JP (2006) Multi-objective optimization of cutting parameters for drilling laminate composite materials by using genetic algorithms. Compos Sci Technol 66:3083–3088. https://doi.org/10.1016/j.compscitech.2006.05.003

Melentiev R, Priarone PC, Robiglio M, Settineri L (2016) Effects of tool geometry and process parameters on delamination in CFRP drilling: an overview. Procedia CIRP 45:31–34. https://doi.org/10.1016/j.procir.2016.02.255

Tsao CC, Hocheng H (2007) Effect of tool wear on delamination in drilling composite materials. Int J Mech Sci 49:983–988. https://doi.org/10.1016/j.ijmecsci.2007.01.001

Park KH, Beal A, Kim DDW, Kwon P, Lantrip J (2011) Tool wear in drilling of composite/titanium stacks using carbide and polycrystalline diamond tools. Wear 271:2826–2835. https://doi.org/10.1016/j.wear.2011.05.038

Jia Z, Fu R, Niu B, Qian B, Bai Y, Wang F (2016) Novel drill structure for damage reduction in drilling CFRP composites. Int J Mach Tools Manuf 110:55–65. https://doi.org/10.1016/j.ijmachtools.2016.08.006

Abrão AM, Rubio JCC, Faria PE, Davim JP (2008) The effect of cutting tool geometry on thrust force and delamination when drilling glass fibre reinforced plastic composite. Mater Des 29:508–513. https://doi.org/10.1016/j.matdes.2007.01.016

Gemi L, Morkavuk S, Köklü U, Gemi DS (2019) An experimental study on the effects of various drill types on drilling performance of GFRP composite pipes and damage formation. Compos Part B Eng 172:186–194. https://doi.org/10.1016/j.compositesb.2019.05.023

Tsao CC, Hocheng H (2005) Effects of exit back-up on delamination in drilling composite materials using a saw drill and a core drill. Int J Mach Tools Manuf 45:1261–1270. https://doi.org/10.1016/j.ijmachtools.2005.01.015

Dogrusadik A, Kentli A (2017) Comparative assessment of support plates’ influences on delamination damage in micro-drilling of CFRP laminates. Compos Struct 173:156–167. https://doi.org/10.1016/j.compstruct.2017.04.031

Dogrusadik A, Kentli A (2019) Experimental investigation of support plates’ influences on tool wear in micro-drilling of CFRP laminates. J Manuf Process 38:214–222. https://doi.org/10.1016/j.jmapro.2019.01.018

Srinivasan T, Palanikumar K, Rajagopal K, Latha B (2017) Optimization of delamination factor in drilling GFR–polypropylene composites. Mater Manuf Process 32:226–233. https://doi.org/10.1080/10426914.2016.1151038

Merino-Pérez JL, Royer R, Merson E, Lockwood A, Ayvar-Soveranis S, Marshall MB (2016) Influence of workpiece constituents and cutting speed on the cutting forces developed in the conventional drilling of CFRP composites. Compos Struct 140:621–629. https://doi.org/10.1016/j.compstruct.2016.01.008

Morkavuk S, Köklü U, Aslantaş K (2022) An experimental comprehensive analysis of drilling carbon fiber reinforced plastic tubes and comparison with carbon fiber reinforced plastic plate. J Reinf Plast Compos. https://doi.org/10.1177/07316844221122041

Morkavuk S, Köklü U, Aslantaş K (2022) An experimental investigation on the influence of different surface curvatures in drilling machinability of carbon fiber reinforced plastic. Proc Inst Mech Eng Part C J Mech Eng Sci 236:10953–10968. https://doi.org/10.1177/09544062221110466

Raj DS, Karunamoorthy L (2018) A new and comprehensive characterisation of tool wear in CFRP drilling using micro-geometry and topography studies on the cutting edge. J Manuf Process 32:839–856. https://doi.org/10.1016/j.jmapro.2018.04.014

Abrão AM, Faria PE, Rubio JCC, Reis P, Davim P (2007) Drilling of fiber reinforced plastics: a review. J Mater Process Technol 186:1–7. https://doi.org/10.1016/j.jmatprotec.2006.11.146

Xu J, Li C, Mi S, An Q, Chen M (2018) Study of drilling-induced defects for CFRP composites using new criteria. Compos Struct 201:1076–1087. https://doi.org/10.1016/j.compstruct.2018.06.051

Tsao CC, Hocheng H (2005) Computerized tomography and C-Scan for measuring delamination in the drilling of composite materials using various drills. Int J Mach Tools Manuf 45:1282–1287. https://doi.org/10.1016/j.ijmachtools.2005.01.009

Obdržálek V, Vrbka J (2011) On the applicability of simple shapes of delaminations in buckling analyses. Compos Part B Eng 42:538–545. https://doi.org/10.1016/j.compositesb.2010.11.006

Persson E, Eriksson I, Zackrisson L (1997) Effects of hole machining defects on strength and fatigue life of composite laminates. Compos Part A Appl Sci Manuf 28:141–151. https://doi.org/10.1016/S1359-835X(96)00106-6

Henerichs M, Voß R, Kuster F, Wegener K (2015) Machining of carbon fiber reinforced plastics: Influence of tool geometry and fiber orientation on the machining forces. CIRP J Manuf Sci Technol 9:136–145. https://doi.org/10.1016/j.cirpj.2014.11.002

Cococcetta NM, Pearl D, Jahan MP, Ma J (2020) Investigating surface finish, burr formation, and tool wear during machining of 3D printed carbon fiber reinforced polymer composite. J Manuf Process 56:1304–1316. https://doi.org/10.1016/j.jmapro.2020.04.025

Tsao CC, Hocheng H (2004) Taguchi analysis of delamination associated with various drill bits in drilling of composite material. Int J Mach Tools Manuf 44:1085–1090. https://doi.org/10.1016/j.ijmachtools.2004.02.019

Haeger A, Schoen G, Lissek F, Meinhard D, Kaufeld M, Schneider G, Schuhmacher S, Knoblauch V (2016) Non-destructive detection of drilling-induced delamination in CFRP and its effect on mechanical properties. Procedia Eng 149:130–142. https://doi.org/10.1016/j.proeng.2016.06.647

Hocheng H, Tsao CC (2007) Computerized tomography and C-scan for measuring drilling-induced delamination in composite material using twist drill and core drill. Key Eng Mater 339:16–20. https://doi.org/10.4028/0-87849-430-8.16

Durão LMP, Tavares JMRS, de Albuquerque VHC, Gonçalves DJS (2013) Damage evaluation of drilled carbon/epoxy laminates based on area assessment methods. Compos Struct 96:576–583. https://doi.org/10.1016/j.compstruct.2012.08.003

Saoudi J, Zitoune R, Mezlini S, Gururaja S, Seitier P (2016) Critical thrust force predictions during drilling: analytical modeling and X-ray tomography quantification. Compos Struct 153:886–894. https://doi.org/10.1016/j.compstruct.2016.07.015

Loja MAR, Alves MSF, Bragança IMF, Rosa RSB, Barbosa ICJ, Barbosa JI (2018) An assessment of thermally influenced and delamination-induced regions by composites drilling. Compos Struct 202:413–423. https://doi.org/10.1016/j.compstruct.2018.02.046

Seif MA, Khashaba UA, Rojas-Oviedo R (2007) Measuring delamination in carbon/epoxy composites using a shadow moiré laser based imaging technique. Compos Struct 79:113–118. https://doi.org/10.1016/j.compstruct.2005.11.039

García-Ordás MT, Alegre-Gutiérrez E, Alaiz-Rodríguez R, González-Castro V (2018) Tool wear monitoring using an online, automatic and low cost system based on local texture. Mech Syst Signal Process 112:98–112. https://doi.org/10.1016/j.ymssp.2018.04.035

Caggiano A, Angelone R, Napolitano F, Nele L, Teti R (2018) Dimensionality reduction of sensorial features by principal component analysis for ANN machine learning in tool condition monitoring of CFRP drilling. Procedia CIRP 78:307–312. https://doi.org/10.1016/j.procir.2018.09.072

Soepangkat BOP, Norcahyo R, Effendi MK, Pramujati B (2020) Multi-response optimization of carbon fiber reinforced polymer (CFRP) drilling using back propagation neural network-particle swarm optimization (BPNN-PSO). Eng Sci Technol an Int J 23:700–713. https://doi.org/10.1016/j.jestch.2019.10.002

Jiao A, Zhang G, Liu B, Liu W (2020) Prediction of manufacturing quality of holes based on a bp neural network. Appl Sci 10. https://doi.org/10.3390/app10062108

Karnik SR, Gaitonde VN, Rubio JC, Correia AE, Abrao AM, Davim JP (2008) Delamination analysis in high speed drilling of carbon fiber reinforced plastics (CFRP) using artificial neural network model. Mater Des 29:1768–1776. https://doi.org/10.1016/j.matdes.2008.03.014

Krishnamoorthy A, Rajendra Boopathy S, Palanikumar K (2011) Delamination prediction in drilling of CFRP composites using artificial neural network. J Eng Sci Technol 6:191–203

Feito N, Milani AS, Muñoz-Sánchez A (2016) Drilling optimization of woven CFRP laminates under different tool wear conditions: a multi-objective design of experiments approach. Struct Multidiscip Optim 53:239–251. https://doi.org/10.1007/s00158-015-1324-y

Poulachon G, Outeiro J, Ramirez C, Andre V, Abrivard G (2016) Hole surface topography and tool wear in CFRP drilling. Procedia CIRP 45:35–38. https://doi.org/10.1016/j.procir.2016.02.348

Iliescu D, Gehin D, Gutierrez ME, Girot F (2010) Modeling and tool wear in drilling of CFRP. Int J Mach Tools Manuf 50:204–213. https://doi.org/10.1016/j.ijmachtools.2009.10.004

Ramirez C, Poulachon G, Rossi F, M’Saoubi R (2014) Tool wear monitoring and hole surface quality during CFRP drilling. Procedia CIRP 13:163–168. https://doi.org/10.1016/j.procir.2014.04.028

Gemi L, Morkavuk S, Köklü U, Yazman Ş (2020) The effects of stacking sequence on drilling machinability of filament wound hybrid composite pipes: part-2 damage analysis and surface quality. Compos Struct 235. https://doi.org/10.1016/j.compstruct.2019.111737

Gemi L, Köklü U, Yazman Ş, Morkavuk S (2020) The effects of stacking sequence on drilling machinability of filament wound hybrid composite pipes: part-1 mechanical characterization and drilling tests. Compos Part B Eng 186. https://doi.org/10.1016/j.compositesb.2020.107787

Wang C, Liu G, An Q, Chen M (2017) Occurrence and formation mechanism of surface cavity defects during orthogonal milling of CFRP laminates. Compos Part B Eng 109:10–22. https://doi.org/10.1016/j.compositesb.2016.10.015

Montoya M, Calamaz M, Gehin D, Girot F (2013) Evaluation of the performance of coated and uncoated carbide tools in drilling thick CFRP/aluminium alloy stacks. Int J Adv Manuf Technol 68:2111–2120. https://doi.org/10.1007/s00170-013-4817-0

Geier N, Szalay T (2017) Optimisation of process parameters for the orbital and conventional drilling of uni-directional carbon fibre-reinforced polymers (UD-CFRP). Meas J Int Meas Confed 110:319–334. https://doi.org/10.1016/j.measurement.2017.07.007

Eneyew ED, Ramulu M (2014) Experimental study of surface quality and damage when drilling unidirectional CFRP composites. J Mater Res Technol 3:354–362. https://doi.org/10.1016/j.jmrt.2014.10.003

Wang F, Qian B, Jia Z, Fu R, Cheng D (2017) Secondary cutting edge wear of one-shot drill bit in drilling CFRP and its impact on hole quality. Compos Struct 178:341–352. https://doi.org/10.1016/j.compstruct.2017.04.024

Girot F, Dau F, Gutiérrez-Orrantia ME (2017) New analytical model for delamination of CFRP during drilling. J Mater Process Technol 240:332–343. https://doi.org/10.1016/j.jmatprotec.2016.10.007

Erturk AT, Vatansever F, Yarar E, Karabay S (2019) Machining behavior of multiple layer polymer composite bearing with using different drill bits. Compos Part B 176:107318. https://doi.org/10.1016/j.compositesb.2019.107318

Tafazzolimoghaddam B, Zhang C (2018) Modelling fracture and delamination in composite laminates : energy release rate and interfacial stress. Compos Struct. https://doi.org/10.1016/j.compstruct.2018.02.006

Chen WC (1997) Some experimental investigations in the drilling of carbon fiber-reinforced plastic (CFRP) composite laminates. Int J Mach Tools Manuf 37:1097–1108. https://doi.org/10.1016/S0890-6955(96)00095-8

Mohan NS, Kulkarni SM, Ramachandra A (2007) Delamination analysis in drilling process of glass fiber reinforced plastic (GFRP) composite materials. J Mater Process Technol 186:265–271. https://doi.org/10.1016/j.jmatprotec.2006.12.043

Davim JP, Rubio JC, Abrao AM (2007) A novel approach based on digital image analysis to evaluate the delamination factor after drilling composite laminates. Compos Sci Technol 67:1939–1945. https://doi.org/10.1016/j.compscitech.2006.10.009

Tsao CC, Kuo KL, Hsu IC (2012) Evaluation of a novel approach to a delamination factor after drilling composite laminates using a core-saw drill. Int J Adv Manuf Technol 59:617–622. https://doi.org/10.1007/s00170-011-3532-y

Lachaud F, Piquet R, Collombet F, Surcin L (2001) Drilling of composite structures. Compos Struct 52:511–516. https://doi.org/10.1016/S0263-8223(01)00040-X

Dharan CKH (1990) Delamination during drilling in composite laminates. J Manu Sci Eng 112:236–239. https://doi.org/10.1115/1.2899580

Ho-Cheng H, Dharan CKH (1990) Delamination during drilling in composite laminates. J Manuf Sci Eng Trans ASME 112:236–239. https://doi.org/10.1115/1.2899580

Acknowledgements

The authors would like to acknowledge the financial support from “National Nature Science Foundation of China (52075380 by Shipeng Li and 5227545 by Xuda Qin)” and the “Natural Science Foundation of Tianjin (21JCYBJC00610 by Shipeng Li).”

Author information

Authors and Affiliations

Contributions

WL: investigation, experimental design, experimental data analysis, processing signals, coding, writing, and editing. XQ: experimental design, review and editing. SL: experimental design, review, and editing. XW: preparation of experimental materials, review, and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, W., Qin, X., Li, S. et al. Experimental research on the matrix cracks and delamination distribution and their monitoring methods during drilling UD-CFRP. Int J Adv Manuf Technol 130, 1595–1615 (2024). https://doi.org/10.1007/s00170-023-12733-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12733-y