Abstract

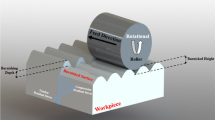

This study aims to evaluate how deep the roller burnishing (RB) operating variables (temperature, number of passes, and load applied by the bearing) affect the surface properties of an Inconel 718 part, in particular the surface roughness and nanohardness, based on nanoindentation results and image analysis techniques by confocal microscopy. It was evaluated how the intensity of these same variables of roller burnishing operations caused the phenomenon of strain-softening. Through the results obtained, it can be noted that, with up to two passes of RB, the surface roughness improves significantly. By increasing the number of RB passes, a discrete phenomenon of strain-softening deformation between the third and fourth RB passes in both operations at room temperature and at 310℃ was verified. For all RB operations (at room temperature and 310℃), the nanohardness levels (HV) were higher than those of the only turned sample, showing that, regardless of the test temperature the nanohardness of the part that underwent the RB operation increased. Metallographic analysis of the samples that underwent RB was performed and the abundant presence of the δ phase was observed. A gap was filled in research involving both the roller burnishing technique and the resulted properties of the Inconel 718.

Similar content being viewed by others

References

Mahto DG, Verma A, Roller Burnishing (2013) A literature review of developments and trends in approach to industrial application. Asian J Eng Technol 01:2321–2462. SSRN: https://ssrn.com/abstract=2774152

Okada M, Suenobu S, Watanabe K, Yamashita Y, Asakawa N (2015) Development and burnishing characteristics of roller burnishing method with rolling and sliding effects. Mechatronics 29:110–118. https://doi.org/10.1016/j.mechatronics.2014.11.002

Schulze V, Bleicher F, Groche P, Guo YB, Pyun YS (2016) Surface modification by machine hammer peening and burnishing. CIRP Ann 65:809–832. https://doi.org/10.1016/j.cirp.2016.05.005

Kurkut V, Chavan ST (2018) Modeling and optimization of surface roughness and microhardness for roller burnishing process using response surface methodology for Aluminum 63400 alloy. Procedia Manuf 20:542–547. https://doi.org/10.1016/j.promfg.2018.02.081

Boozarpoor M, Teimouri R (2021) Parametric study of multi-roller rotary burnishing process. Int J Light Mater Manuf 4:179–194. https://doi.org/10.1016/j.ijlmm.2020.10.001

El-Axir MH, Othmanb OM, Abodiena AM (2008) Improvements in out-of-roundness and microhardness of inner surfaces by internal ball burnishing process. J Mater Process Technol 196:120–128. https://doi.org/10.1016/j.jmatprotec.2007.05.028

Zhao J, Liu Z, Wang B, Cai Y, Song Q (2020) Analytical prediction and experimental investigation of burnishing force in rotary ultrasonic roller burnishing titanium alloy Ti–6Al–4V. J Manuf Sci Eng Trans ASME 142:031004–1/031004–9. https://doi.org/10.1115/1.4046027

Brezeanu LC (2015) Contact stresses between two cylindrical bodies: cylinder and cylindrical cavity with parallel axes – part I: theory and FEA 3D modeling. Procedia Technol 19:169–176. https://doi.org/10.1016/j.protcy.2015.02.025

Kułakowska A, Bohdal Ł (2020) Researches and simulation of elastic recovery phenomena during roller burnishing process of macro-asperities of surface. Materials 13(5276):19p. https://doi.org/10.3390/ma13225276

Kowalik M, Mazur T, Trzepiecinski T (2018) Assessment of the depth of the deformed layer in the roller burnishing process. Strength Mater 3:493–503. http://dspace.nbuv.gov.ua/handle/123456789/173917

Saritha PA (2014) Study on assessment of theories for contact stress distribution at roller - work piece contact in roller burnishing. International Journal of Science. Eng Technol Res (IJSETR) 01:100–106 (ISSN: 2278 – 7798)

Rotella G, Filice L, Micari F (2020) Improving surface integrity of additively manufactured GP1 stainless steel by roller burnishing. CIRP Ann 01:513–516. https://doi.org/10.1016/j.cirp.2020.04.015

Smirnov AV, Kuznetsova VA (2018) Factors affecting the surface roughness in burnishing. Russ Eng Res 10:814–817. https://doi.org/10.3103/S1068798X18100155

Capello E (2005) Residual stresses in turning. Part I: influence of process parameters. J Mater Process Technol 160:221–228. https://doi.org/10.1016/j.jmatprotec.2004.06.012

Capello E (2006) Residual stresses in turning. Part II. Influence of the machined material. J Mater Process Technol 172:319–326. https://doi.org/10.1016/j.jmatprotec.2005.10.009

Azarbarmas M, Aghaie-Khafria M, Cabrera JM, Calvo J (2016) Dynamic recrystallization mechanisms and twining evolution during hot deformation of Inconel 718. Mater Sci Eng, A 678:137–152. https://doi.org/10.1016/j.msea.2016.09.100

Bei H, Xia YZ, Barabash RI, Gao YF (2016) A tale of two mechanisms: strain-softening versus strain-hardening in single crystals under small stressed volumes. Scripta Mater 01:48–52. https://doi.org/10.1016/j.scriptamat.2015.07.043

Klotz T, Blas S, Lévesque M, Brochu M (2017) 1D cyclic yield model independent of load spectrum characteristics and its application to Inconel 718. Mech Mater 109:34–41. https://doi.org/10.1016/j.mechmat.2017.03.011

Leppert T, Peng RL (2009) Surface residual stresses in dry turning of 0.45% C steel. International Centre for Diffraction Data, 304–311. ISSN 1097–0002,

Caruso S, Umbrello D, Outeiro JC, Filice L, Micari F (2011) An experimental investigation of residual stresses in hard machining of AISI 52100 steel. Procedia Eng 19:67–72. https://doi.org/10.1016/j.proeng.2011.11.081

Chamanfar A, Sarrat L, Jahazi M, Asadi M, Weck A, Koul AK (2013) Microstructural characteristics of forged and heat treated Inconel-718 disks. Mater Des 52:791–800. https://doi.org/10.1016/j.matdes.2013.06.004

Anderson M, Thielin AL, Bridier F, Bocher P, Savoie J (2017) δ Phase precipitation in Inconel 718 and associated mechanical properties. Mater Sci Eng, A 679:48–55. https://doi.org/10.1016/j.msea.2016.09.114

Anbarasan N, Gupta BK, Prakash S, Muthukumar P, Oyyaravelu R, Kumar RJF, Jerome S (2018) Effect of heat treatment on the microstructure and mechanical properties of Inconel 718. Mater Today: Proc 5:7716–7724. https://doi.org/10.1016/j.matpr.2017.11.448

Fu T, Peng X, Chen X, Weng S, Hu N, Li Q, Wang Z (2016) Molecular dynamics simulation of nanoindentation on Cu/Ni nanotwinned multilayer films using a spherical indenter. Sci Rep 6(35665):10p. https://doi.org/10.1038/srep35665

Voyiadjis GZ, Yaghoobi M (2017) Review of nanoindentation size effect: experiments and atomistic simulation. Crystals 7(321):28p. https://doi.org/10.3390/cryst7100321

Ruestes CJ, Alhafez IA, Urbassek HM (2017) Atomistic studies of nanoindentation—a review of recent advances. Crystals 7(293):15p. https://doi.org/10.3390/cryst7100293

Merle B, Maier-Kiener V, Pharr GM (2017) Influence of modulus-to-hardness ratio and harmonic parameters on continuous stiffness measurement during nanoindentation. Acta Mater 01:167–176. https://doi.org/10.1016/j.actamat.2017.05.036

Hua Y, Liu Z, Wang B, Ho X (2019) Surface modification through combination of finish turning with low plasticity burnishing and its effect on fatigue performance for Inconel 718. Surf Coat Technol 15:508–517. https://doi.org/10.1016/j.surfcoat.2019.07.057

Yuan H, Liu WC (2005) Effect of the δ phase on the hot deformation behavior of Inconel 718. Mater Sci Eng, A 408:281–289. https://doi.org/10.1016/j.msea.2005.08.126

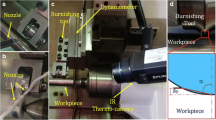

Casarin SJ, De Angelo Sanchez LE, Bianchi EC, Scalon VL, Fragelli RL, De Godoi EL, Cindra Fonseca MP (2021) Effect of burnishing on Inconel 718 workpiece surface heated by infrared radiation. Mater Manuf Processes 36:1853–1864. https://doi.org/10.1080/10426914.2021.1926494

Acknowledgements

The authors also thank Dr. Paulo Noronha Lisboa Filho (Dept. Physics Unesp Bauru) for making the confocal microscope available to this research and Dr. Paulo César Soares Júnior (Pontifical Catholic University of Paraná, Polytechnic School, Department of Mechanical Engineering, Curitiba-Brazil) for making the indentations tests to this research.

Funding

This work was supported by CAPES- Brazil. Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES) – Grant number: 88882.317754/2019–01.

Author information

Authors and Affiliations

Contributions

Eduardo Luiz de Go methodology, investigation, and formal analysis. Samuel José Casarin: conceptualization and writing—original draft and editing. Gilberto de Magalhães Bento Gonçalves: writing—reviewing and editing. Luiz Eduardo de Angelo Sanchez: project administration, resources, and validation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

de Godoi, E.L., Casarin, S.J., de Magalhães Bento Gonçalves, G. et al. Relationship of the roller burnishing process parameters with the surface and subsurface properties of Inconel 718. Int J Adv Manuf Technol 129, 5359–5370 (2023). https://doi.org/10.1007/s00170-023-12672-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12672-8