Abstract

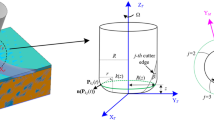

Due to the complex integral structure design of the deep cavity parts, large overhang bent-blade cutter is used to machining such parts. Thus, the tools’ complex geometry structure, large overhang, and low stiffness, resulting in lateral, axial, and torsional vibration in the machining process, making the actual machining trajectory deviate from the theoretical value, seriously affect the processing quality, producing violent vibration. Therefore, this paper established a model to predict the surface topography of bent-blade cutter considering the combined vibration effect of bending and torsion, including the complicated process geometries, varying tool profiles, and multi-direction vibrations. The influencing factors of the turning surface topography are studied. Meanwhile, based on the cutting edge trajectory, the surface topography is simulated and analyzed by considering the static offset and dynamic vibration of the tool. Besides, based on the extended Timoshenko beam model (E-TBM) theory, the control equation of bent-blade cutter considering the combined effect of bending and torsion is derived and solved by finite element method (FEM). Finally, a series of turning experiments are carried out to verify the accuracy and efficiency of the presented model. The influence rule of turning parameters on surface roughness was studied by theoretical and experimental results, and the turning parameters were optimized to improve the machining quality and accuracy of deep cavity parts.

Similar content being viewed by others

Abbreviations

- A :

-

Area of cross-section, mm2

- B 2 :

-

Width of cutter board II, mm

- C :

-

Equivalent damping

- B 3 :

-

Length of cutter board III, mm

- D :

-

Diameter of cutter board I, mm

- G :

-

S hear modulus

- H 1 :

-

Height of cutter board I and II, mm

- H 2 :

-

Height of cutter board III, mm

- I b :

-

Inertia moment of cutter bar, m4

- I p :

-

Inertia moment of cutter board, m4

- K :

-

Equivalent stiffness

- K N :

-

Element stiffness matrix

- M :

-

Equivalent mass

- M N :

-

Element mass matrix

- L 1 :

-

Total length of bent-blade cutter, mm

- L 2 :

-

Length of cutter board II, mm

- T :

-

Kinetic energy, J

- T :

-

Transformation matrix

- δ :

-

Engagement angle

- U :

-

Strain energy, J

- Ω:

-

Volume of cross-section, mm3

- W :

-

Work done by external force and torque, J

- J :

-

Polar moment of inertia, m4

- a p :

-

Depth of cut, mm

- b :

-

Width of cut, mm

- f :

-

Feed rate, mm/r

- h :

-

Thickness of cut, mm

- n :

-

Spindle speed, rmp

- r :

-

Radius of the circular insert, mm

- w :

-

Transverse displacement, m

- ϕ :

-

Twist angular displacement, rad

- θ :

-

Rotation angular displacement, rad

- M :

-

Torque, N/m

- ψ :

-

Warping displacement, rad

- n :

-

Spindle speed, rmp

- v :

-

Poisson’s ratio

- ρ :

-

Density, kg/m3

- l :

-

Sampling length, mm

- Ω:

-

Volume of cross-section, mm3

- k * :

-

Ratio of the normal cutting force to the tangential cutting force

- ε :

-

Angular location of the infinitesimal segment at the cutting edge

- E-TBM:

-

Extended Timoshenko Beam Model

- FEM:

-

Finite element method

- EBM:

-

Euler-Bernoulli beam model

- TBM:

-

Timoshenko Beam Model

- SVT:

-

Saint Venant Theory

References

Liu SM, Shao XD, Ge XB, Wang D (2017) Simulation of the deformation caused by the machining cutting force on thin-walled deep cavity parts. Int J Adv Manuf Technol 92:3503–3517

Zhang Z, Li H, Liu XB, Zhang WY, Meng G (2018) Chatter mitigation for the milling of thin-walled workpiece. Int J Mech Sci 138–139:262–271

Wang DQ, Löser M, Wang XB, Liu ZB (2019) Milling stability analysis with considering process damping and mode shapes of in-process thin-walled workpiece. Int J Mech Sci 159:382–397

Peng ZL, Zhang DY, Zhang XY (2020) Chatter stability and precision during high-speed ultrasonic vibration cutting of a thin-walled titanium cylinder. Chinese J Aeronaut 12:3535–3549

Roukema JC, Altintas Y (2007) Generalized modeling of drilling vibrations, part II: chatter stability in frequency domain. Int J Mach Tools Manuf 47:1474–1485

Ahmadi K, Altintas Y (2013) Stability of lateral, torsional and axial vibrations in drilling. Int J Mach Tools Manuf 68:63–74

Wojciechowskia S, Twardowskia P, Pelica M, Marudab RW, Barransc S, Krolczykd GM (2016) Precision surface characterization for finish cylindrical milling with dynamic tool displacements model. Precis Eng 46:158–165

Ma YC, Wan M, Yang Y, Zhang WH (2019) Dynamics of tapping process. Int J Mach Tools Manufe 140:34–47

Voronov SA, Ivanov II, Kiselev IA (2015) Investigation of the milling process based on a reduced dynamic model of cutting tool. J Mach Manuf Reliab 44(1):70–78

Ertürk A, Ozgüven HN, Budak E (2006) Analytical modeling of spindle-tool dynamics on machine tools using Timoshenko beam model and receptance coupling for the prediction of tool point FRF. Int J Mach Tools Manuf 46(15):1901–1912

Sun T, Qin LF, F YC, Hou JM, (2019) Chatter stability of orthogonal turn-milling analyzed by complete discretization method. Precis Eng 56:87–95

Monkova K, Monka P, Cizikova A (2015) Modal analysis as the base of dynamic analysis. Appl Mech Mater 798:148–152

Shi JH, Song QH, Liu ZQ, Wan Y (2017) Formulating a numerically low-cost method of a constrained layer damper for vibration suppression in thin-walled component milling and experimental validation. Int J Mech Sci 128–129:294–311

Takahashi H, Yuki T, Suzuki K (2016) Modeling of ball screw driven stage for drilling machines with lumped parameter system model and FEM model. Mech Eng J 3(4):16–00068

Slavik A (2012) Dynamic equations on time scales and generalized ordinary differential equations. J Math Anal Appl 385(1):534–550

Kotaiah KR, Srinivas J (2010) Dynamic analysis of a turning tool with a discrete model of the workpiece. Proc Inst Mech Eng Part B: J Eng Manuf 224(B2):207–217

Wu YL, Song QH, Liu ZQ, Wang B (2019) Stability of turning process with a distributed cutting force model. Int J Adv Manuf Technol 102:1215–1225

Filiz S, Ozdoganlar OB (2008) Micro end mill dynamics including the actual fluted geometry and setup errors-part I: model development and numerical solution. J Manuf Sci Eng 130(3):031119

Kim DS, Chang IC, Kim SW (2002) Microscopic topographical analysis of tool vibration effects on diamond turned optical surfaces. Precis Eng 26:168–174

Wang H, To S, Chan CY, Cheung CF, Lee WB (2010) A theoretical and experimental investigation of the tool-tip vibration and its influence upon surface generation in single-point diamond turning. Int J Mach Tools Manuf 50(3):241–252

Gao Y, Sun RL, Chen YN, Leopold J (2016) Analysis of chip morphology and surface topography in modulation assisted machining. Int J Mech Sci 111:80–100

Mann JB, Saldana CJ, Guo Y, Yeung H, Compton WD, Chandrasekar S (2013) Effects of controlled modulation on surface textures in deep-hole drilling. Int J Mater Manuf 6:24–32

Arizmendi M, Campa FJ, Fernández J, Lamikiz A (2009) Model for surface topography prediction in peripheral milling considering tool vibration. CIRP Ann Manuf Technol 58(1):93–96

Yuan YJ, Jing XB, Ehmann KF, Zhang DW (2018) Surface roughness modeling in micro end-milling. Int J Adv Manuf Technol 95:1655–1664

Santoro R (2010) The line element-less method analysis of orthotropic beam for the De Saint Venant torsion problem. Int J Mech Sci 52(1):43–55

Kahrobaiyan MH, Asghari M, Ahmadian MT (2014) A Timoshenko beam element based on the modified couple stress theory. Int J Mech Sci 79:75–83

Du Y, Song QH, Liu ZQ, Wang B, Wan Y (2019) Size-dependent responses of micro-end mill based on strain gradient elasticity theory. Int J Adv Manuf Technol 100(5–8):1839–1854

Weng J, Zhuang K, Chen D, Ding GSS (2017) An analytical force prediction model for turning operation by round insert considering edge effect. Int J Mech Sci 128:168–180

Weng J, Zhuang KJ, Zhu DH, Guo SS, Ding H (2018) An analytical model for the prediction of force distribution of round insert considering edge effect and size effect. Int J Mech Sci 138:86–98

Wang YN, Yan J (2019) A variational principle for contact Hamiltonian systems. J Differ Equations 267(7):4047–4088

Orra K, Choudhury SK (2018) Mechanistic modelling for predicting cutting forces in machining considering effect of tool nose radius on chip formation and tool wear land. Int J Mech Sci 142:255–268

Lee AC, Hoang TD (2016) Coupled lateral and torsional vibrations of the micro-drilling spindle systems. Int J Adv Manuf Technol 87(5–8):2063–2079

Funding

The study was financially supported by the National Natural Science Foundation of China (grant numbers 52275445 and 51922066) and the Key Research and Development Plan of Shandong Province (grant numbers 2021JMRH0301 and 2020CXGC010204).

Author information

Authors and Affiliations

Contributions

X.W. and Q.S. contributed the central idea, analyzed most of the data, and wrote the initial draft of the paper. X.W. contributed to refining the ideas, carrying out additional analyses, and finalizing this paper.

Corresponding author

Ethics declarations

Ethics approval and consent to participate

Not applicable.

Consent for publication

The consent to submit this paper has been received explicitly from all authors.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix 1

Appendix 2

Appendix 3

Appendix 4

Appendix 5

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, X., Song, Q. Dynamic analysis and surface morphology prediction for deep cavity turning of bent-blade cutter. Int J Adv Manuf Technol 129, 4435–4455 (2023). https://doi.org/10.1007/s00170-023-12606-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12606-4