Abstract

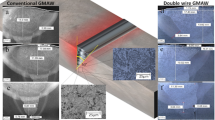

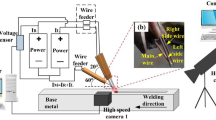

Sheet metal components are widely used in automobiles, home appliances, aerospace, and other industries. Gas–metal arc welding (GMAW) easily produces welding defects such as bending deformation and burn-through. However, variable-polarity gas–metal arc welding (VP-GMAW) features low heat input. In this paper, a VP-GMAW waveform is proposed, whose feasibility is proven by a welding process analysis. A model of short-circuit transition was established, and comparative experiments were conducted. With the adjustment of welding parameters in the short-circuit stage and arc-burning stage, the influence of each parameter on the welding process is sorted out by analyzing the weld geometries and microstructures. Furthermore, the effect of electrode negative (EN) ratio on weld microstructure, microhardness, and tensile property is emphasized. The result shows that the welding parameters in the short-circuit stage mainly affect the welding spatter, and the parameters in the arc-burning stage mainly affect the weld geometry. With the increase of the EN ratio, the microstructure grain of the weld bead is refined, and the hardness and tensile strength of the joint are improved. Compared with traditional welding methods, the current waveform proposed in VP-GMAW can obtain fewer splashes and better weld morphology.

Similar content being viewed by others

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding author on reasonable request.

References

Deng D, Zhou YJ, Bi T, Liu XZ (2013) Experimental and numerical investigations of welding distortion induced by CO2 gas arc welding in thin-plate bead-on joints. Mater Des 52:720–729. https://doi.org/10.1016/j.matdes.2013.06.013

Wang JC, Shibahara M, Zhang XD, Murakawa H (2012) Investigation on twisting distortion of thin plate stiffened structure under welding. J Mater Process Technol 212(8):1705–1715. https://doi.org/10.1016/j.jmatprotec.2012.03.015

Remes H, Fricke W (2014) Influencing factors on fatigue strength of welded thin plates based on structural stress assessment. Welding in the World 58(6):915–923. https://doi.org/10.1007/s40194-014-0170-7

Cunha TV (2013) Proposal of roadmap for determining the variables of pulsed TIG welding process applied to welding of thin plates. Soldagem Insp 18:64–71. https://doi.org/10.1590/S0104-92242013000100009

Wang LL, Wei JH, Wang ZM (2018) Numerical and experimental investigations of variable polarity gas tungsten arc welding. Int J Adv Manuf Technol 95:2421–2428. https://doi.org/10.1007/s00170-017-1387-6

Li GJ, Zhang PL, Wu X, Nie YP, Yu ZS, Yan H, Lu QH (2018) Gap bridging of 6061 aluminum alloy joints welded by variable-polarity cold metal transfer. J Mater Process Technol 255:927–935. https://doi.org/10.1016/j.jmatprotec.2018.01.004

Zhang BW, Wang C, Wang ZH, Zhang LQ, Gao Q (2019) Microstructure and properties of Al alloy ER5183 deposited by variable polarity cold metal transfer. J Mater Process Technol 267:167–176. https://doi.org/10.1016/j.jmatprotec.2018.12.011

Qiu L, Yang CL, Lin SB, Fan CL (2009) Effect of pulse current on microstructure and mechanical properties of variable polarity arc weld bead of 2219–T6 aluminium alloy. Mater Sci Technol 25:739–742. https://doi.org/10.1179/174328408X383766

Wu KY, Zhan JT, Cao XW, Zeng M, Ding N (2020) Metal transfer of aluminum alloy double-wire pulsed GMAW with a median waveform. J Mater Process Technol 286:1–16. https://doi.org/10.1016/j.jmatprotec.2020.116761

Mvola B, Kah P, Layus P (2018) Review of current waveform control effects on weld geometry in gas metal arc welding process. Int J Adv Manuf Technol 96:4243–4265. https://doi.org/10.1007/s00170-018-1879-z

Wang L, Heng G, Chen H, Xue JX, Lin F, Huang WJ (2016) Methods and results regarding sinusoid modulated pulse gas metal arc welding. Int J Adv Manuf Technol 86:1841–1851. https://doi.org/10.1007/s00170-015-8267-8

Zhu Q, Xue JX, Yao P (2015) Gaussian pulsed current waveform welding for aluminum alloys. Mater Manuf Process 30:1124–1130. https://doi.org/10.1080/10426914.2014.973603

Kohei F, Tadahisa T, Masahiro O, Takashi M, Mukai N, Yoshihide I (2021) Experiment study on the metal transfer control by using pulsed Ar addition in CO2 arc welding process: studies on pulsed gas MAG welding. Weld Int 34:7–9. https://doi.org/10.2207/qjjws.38.379

Zhao Y, Chung H (2017) Numerical simulation of droplet transfer behavior in variable polarity gas metal arc welding. Int J Heat Mass Transf 111:1129–1141. https://doi.org/10.1016/j.ijheatmasstransfer.2017.04.090

Jorge VL, Scotti FM, Reis RP, Socotti A (2021) Wire feed pulsation as a means of inducing surface tension transfer in Gas Metal Arc Welding. J Manuf Process 62:655–669. https://doi.org/10.1016/j.jmapro.2020.12.072

Song G, Wang P, Liu LM (2010) Study on ac-PMIG welding of AZ(31)B magnesium alloy. Sci Technol Weld Join 15:219–225. https://doi.org/10.1179/136217110X12665048207656

Park HJ, Kim DC, Kang MJ, Rhee S (2013) The arc phenomenon by the characteristic of EN ratio in AC pulse GMAW. Int J Adv Manuf Technol 66(5):867–875. https://doi.org/10.1007/s00170-012-4371-1

Nascimento AS, Fernandes DB, Mota CAM, Vilarinho L (2009) Methodology for determination of parameters for welding MIG with variable polarity. Weld Int 23(6):473–480. https://doi.org/10.1080/09507110802543435

Kumar R, Dilthey U, Dwivedi DK, Ghosh PK (2009) Thin sheet welding of Al 6082 alloy by AC pulse-GMA and AC wave pulse-GMA welding. Mater Des 30:306–313. https://doi.org/10.1016/j.matdes.2008.04.073

Meneses VA, Leal VS, Scotti A (2016) Influence of metal transfer stability and shielding gas composition on CO and CO2 emissions during short-circuiting MIG/MAG Welding. Soldagem Insp 21:253–268. https://doi.org/10.1590/0104-9224/SI2103.02

Huang Y, Li F, Zhang YL, Cai Y, Hua XM (2019) Spectral analysis of the dynamic behavior of a welding arc during pulsed gas metal arc welding of AA5083 aluminum alloy with ER5183 wire. IEEE Trans Plasma Sci 47:5078–5087. https://doi.org/10.1109/TPS.2019.2948205

Dhivyasri G, Rahul SG, Kavitha P, Arungalai VS, Ramesh KKA, Gao L, Garg A (2018) Dynamic control of welding current and welding time to investigate ultimate tensile strength of miab welded T11 tubes. J Manuf Process 32:564–581. https://doi.org/10.1016/j.jmapro.2018.03.031

Chang YL, Liu XL, Lu L, Babkin AS, Lee BY, Gao F (2014) Impacts of external longitudinal magnetic field on arc plasma and droplet during short-circuit GMAW. Int J Adv Manuf Technol 70(9):1543–1553. https://doi.org/10.1007/s00170-013-5403-1

Acknowledgements

The authors would like to thank the editorial department and the reviewers

Funding

This work was supported by the Natural Science Foundation of Guangdong, China (No. 2021A1515011773), the Enterprise Science and Technology Commissioner Funding Project of Guangdong, China (No. GDKTP2021024300), and the Key Research Project of Guangzhou, China (No.2023B03J1329).

Author information

Authors and Affiliations

Contributions

The conceptualization and manuscript were conducted by MZ, ZL, and ZH. The data analysis was completed by ZW. Funding acquisition and manuscript review were performed by MZ. XJ provided the experiment equipment. All the authors took part in the paper.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Written informed consent for publication was obtained from all participants.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zeng, M., Li, Z., Hu, Z. et al. The effects of welding parameters on metal transfer and bead properties in the variable-polarity GMAW of mild steel. Int J Adv Manuf Technol 129, 4165–4183 (2023). https://doi.org/10.1007/s00170-023-12579-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12579-4