Abstract

TB6 titanium alloy has the characteristics of high strength, high fatigue life, and low stiffness, making it a favored choice for critical load-bearing components in helicopters and large passenger aircraft. However, it is difficult to realize efficient and high-quality processing of TB6 by using traditional mechanical cutting technology because of its inherent characteristics. Electrochemical jet machining technology can dissolve materials through electrochemistry, which has prominent advantages such as no cutting force and high processing flexibility, making it a promising method for achieving efficient and high-quality TB6 titanium alloy processing. This paper focuses on the electrochemical dissolution behaviors of TB6 titanium alloy, as well as the electrochemical jet machining characteristics. The current efficiency and polarization curves of TB6 titanium alloy in different solutions were tested at different temperatures. The phenomenon of bubble generation and black product falling during the test was captured. The surface dissolution process of TB6 titanium alloy at different current densities was investigated through scanning electron microscope pictures. Finally, the electrochemical jet machining experiment was conducted. The surface characteristics of the micro-grooves obtained by electrochemical jet machining, including morphology, cross-sectional profile, and surface roughness, were explored. The research findings revealed that, at high current densities exceeding 200 A/cm2, electrochemical dissolution exhibited greater uniformity while stray corrosion was significantly reduced. Excellent surface quality with a minimum surface roughness of Ra 0.373 μm was achieved in electrochemical jet machining of TB6 titanium alloy with 20 wt% NaCl solution.

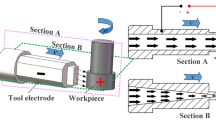

Graphical abstract

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Zhao Q, Sun Q, Xin S, Chen Y, Wu C, Wang H, Xu J, Wan M, Zeng W, Zhao Y (2022) High-strength titanium alloys for aerospace engineering applications: a review on melting-forging process. Mat Sci Eng A 845:143260

Lin Z, Song K, Yu X (2021) A review on wire and arc additive manufacturing of titanium alloy. J Manuf Process 70:24–45

Liu Z, He B, Lyu T, Zou Y (2021) A review on additive manufacturing of titanium alloys for aerospace applications: directed energy deposition and beyond Ti-6Al-4V. JOM 73:1804–1818

Enrui Z, Xia C, Cheng T, Delai O (2022) Simulation of texture evolution of TB6 titanium alloy cylindrical parts during spinning. Mater Today Commun 33:104815

Liu Y, Qu N (2020) Obtaining high surface quality in electrolyte jet machining TB6 titanium alloy via enhanced product transport. J Mater Process Tech 276:116381

Liu Y, Qu N, Qiu Z (2022) Flow field simulation and experimental investigation on macro electrolyte jet electrochemical turning of TB6 titanium alloy. Int J Adv Manuf Tech 120:2617–2632

Deng H, Jiao Z, Cheng X, Qi S, Tian X, Wang Y, Zhang S (2023) Effect of double annealing treatments on Ti-10V-2Fe-3Al alloy by directed energy deposition. Mater Sci Tech 39:1792–1801

Wei D, Li F, Li S, Wang S, Ding F, Tian T, Zhang P, Yao Z (2020) Effect of Cr ion implantation on surface morphology, lattice deformation, nanomechanical and fatigue behavior of TC18 alloy. Appl Surf Sci 506:145023

Sun J, Huang S, Wang T, Chen W (2018) Research on surface integrity of turning titanium alloy TB6. Procedia Cirp 71:484–489

Wang X, Qu N, Fang X (2019) Reducing stray corrosion in jet electrochemical milling by adjusting the jet shape. J Mater Process Tech 264:240–248

Speidel A, Bisterov I, Saxena KK, Zubayr M, Reynaerts D, Natsu W, Clare AT (2022) Electrochemical jet manufacturing technology: from fundamentals to application. Int J Mach Tool Manu 180:103931

Xue J, Dong B, Zhao Y (2022) Significance of waveform design to achieve bipolar electrochemical jet machining of passivating material via regulation of electrode reaction kinetics. Int J Mach Tool Manu 177:103886

Kunieda M, Mizugai K, Watanabe S, Shibuya N, Iwamoto N (2011) Electrochemical micromachining using flat electrolyte jet. CIRP Ann Manuf Technol 60:251–254

Kawanaka T, Kato S, Kunieda M, Murray JW, Clare AT (2014) Selective surface texturing using electrolyte jet machining. Procedia Cirp 13:345–349

Bisterov I, Abayzeed S, Speidel A, Clare AT (2022) On-machine measurement with an electrochemical jet machine tool. Int J Mach Tool Manu 174:103859

Mitchell-Smith J, Speidel A, Gaskell J, Clare AT (2017) Energy distribution modulation by mechanical design for electrochemical jet processing techniques. Int J Mach Tool Manu 122:32–46

Kunar S (2022) Micro-electrochemical jet machining of large area microtexturing with tool movement strategy. Mater Manuf Process 37:674–680

Schubert A, Hackert-Oschätzchen M, Martin A, Winkler S, Kuhn D, Meichsner G, Zeidler H, Edelmann J (2016) Generation of complex surfaces by superimposed multi-dimensional motion in electrochemical machining. Procedia Cirp 42:384–389

Zhan S, Lyu Z, Dong B, Liu W, Zhao Y (2023) Cathodic discharge plasma in electrochemical jet machining: Phenomena, mechanism and characteristics. Int J Mach Tool Manu 187:104015

Luo J, Fang X, Zhu D (2020) Jet electrochemical machining of multi-grooves by using tube electrodes in a row. J Mater Process Tech 283:116705

Mishra K, Dey D, Sarkar BR, Bhattacharyya B (2017) Experimental investigation into electrochemical milling of Ti6Al4V. J Manuf Process 29:113–123

Liu WD, Luo Z, Li Y, Liu ZM, Li KB, Xu JX, Ao SS (2019) Investigation on parametric effects on groove profile generated on Ti1023 titanium alloy by jet electrochemical machining. Int J Adv Manuf Tech 100:2357–2370

Cheng H, Cui P, Wang F, Ding LX, Wang H (2019) High efficiency electrochemical nitrogen fixation achieved with a lower pressure reaction system by changing the chemical equilibrium. Angew Chem 131:15687–15693

Angulo A, Van Der Linde P, Gardeniers H, Modestino M, Rivas DF (2020) Influence of bubbles on the energy conversion efficiency of electrochemical reactors. Joule 4:555–579

Zhang B, Wang J, Wu B, Guo XW, Wang YJ, Chen D, Zhang YC, Du K, Oguzie EE, Ma XL (2018) Unmasking chloride attack on the passive film of metals. Nat Commun 9:2559

Chen X, Xu Z, Zhu D, Fang Z, Zhu D (2015) Experimental research on electrochemical machining of titanium alloy Ti60 for a blisk. Chinese J Aeronaut 29:274–282

Speidel A, Mitchell-Smith J, Bisterov I, Clare AT (2019) Oscillatory behaviour in the electrochemical jet processing of titanium. J Mater Process Tech 273:116264

Wang D, Zhu Z, Wang N, Zhu D, Wang H (2015) Investigation of the electrochemical dissolution behavior of Inconel 718 and 304 stainless steel at low current density in NaNO3 solution. Electrochim Acta 156:301–307

Sazou D, Saltidou K, Pagitsas M (2012) Understanding the effect of bromides on the stability of titanium oxide films based on a point defect model. Electrochim Acta 76:48–61

He B, Wang D, Zhang J, Lei W (2022) Investigation of electrochemical dissolution behavior of near-α Ta15 titanium alloy in NaCl solution with low-frequency pulse current. J Electrochem Soc 169:043515

Qin T, Lin X, Yu J, Wang M, Guo P, Li J, Zhang Y, Liu J, Zhang S, Huang W (2021) Performance of different microstructure on electrochemical behaviors of laser solid formed Ti-6Al-4V alloy in NaCl solution. Corros Sci 185:109392

Li HS, Gao CP, Wang GQ, Qu NS, Zhu D (2016) A study of electrochemical machining of Ti-6Al-4V in NaNO3 solution. Sci Rep 6:35013

Guo P, Lin X, Ren Y, Xu J, Li J, Zhang Y, Chen J, Huang W (2018) Microstructure and electrochemical anodic behavior of Inconel 718 fabricated by high-power laser solid forming. Electrochim Acta 276:247–260

Li Y, You Y, Lv X (2022) Comparative study on the crack growth behaviours of E690 steel and heat-affected zone microstructures under cathodic potential in artificial seawater based on mechano-electrochemical effect at crack tip. Corros Sci 198:110103

Weinmann M, Stolpe M, Weber O, Busch R, Natter H (2015) Electrochemical dissolution behaviour of Ti90Al6V4 and Ti60Al40 used for ECM applications. J Solid State Electr 19:485–495

Chen X, Xu Z, Zhu D, Fang Z, Zhu D (2016) Experimental research on electrochemical machining of titanium alloy Ti60 for a blisk. Chinese J Aeronaut 29:274–282

Yang X, Du C, Wan H, Liu Z, Li X (2018) Influence of sulfides on the passivation behavior of titanium alloy TA2 in simulated seawater environments. Appl Surf Sci 458:198–209

Gao A, Hang R, Bai L, Tang B, Chu PK (2018) Electrochemical surface engineering of titanium-based alloys for biomedical application. Electrochim Acta 271:699–718

Liu WD, Ao SS, Li Y, Liu Z, Zhang H, Manladan SM, Luo Z, Wang Z (2017) Effect of anodic behavior on electrochemical machining of TB6 titanium alloy. Electrochim Acta 233:190–200

Hackert-Oschätzchen M, Paul R, Martin A, Meichsner G, Lehnert N, Schubert A (2015) Study on the dynamic generation of the jet shape in jet electrochemical machining. J Mater Process Tech 223:240–251

Matthias H-O, Paul R, Kowalick M, Martin A, Meichsner G, Schubert A (2015) Multiphysics simulation of the material removal in jet electrochemical machining. Procedia Cirp 31:197–202

Mitchell-Smith J, Speidel A, Clare AT (2018) Advancing electrochemical jet methods through manipulation of the angle of address. J Mater Process Tech 255:364–372

Kawanaka T, Kunieda M (2015) Mirror-like finishing by electrolyte jet machining. Cirp Ann-Manuf Techn 64:237–240

Funding

This work was supported by the National Natural Science Foundation of China (No. 52205468), China Postdoctoral Science Foundation (No. 2022M710061 and No. 2023T160277), Natural Science Foundation of Jiangsu Province (No. BK20210755), Science and Technology Innovation Major Project of Wenzhou (No. ZG2022007), and Natural Science Research of Jiangsu Higher Education Institutions of China (No. 21KJB460014).

Author information

Authors and Affiliations

Contributions

Yang Liu: methodology, conceptualization, writing—original draft, writing—review and editing, funding acquisition. Pengfei Ouyang: methodology, writing—original draft, writing—review and editing. Zhaoyang Zhang: data curation, funding acquisition, supervision. Yufeng Wang: methodology, writing—review and editing, supervision. Hao Zhu: writing—review and editing, supervision. Kun Xu: methodology, writing—review and editing.

Corresponding authors

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

The authors declare that they consent to participate this paper.

Consent for publication

The authors declare that they consent to publish this paper and agree with the publication.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Highlights

• The phenomenon of bubble generation and black product falling during the test was captured.

• Electrochemical jet machining TB6 titanium alloy with 20 wt% NaCl solution achieved excellent surface quality with a minimum surface roughness of Ra 0.373 μm.

• The electrochemical dissolution behaviors of TB6 titanium alloy, as well as the electrochemical jet machining characteristics, were analyzed.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, Y., Ouyang, P., Zhang, Z. et al. Electrochemical dissolution behavior and electrochemical jet machining characteristics of titanium alloy in high concentration salt solution. Int J Adv Manuf Technol 129, 3595–3607 (2023). https://doi.org/10.1007/s00170-023-12530-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12530-7