Abstract

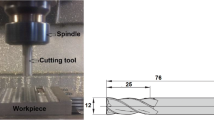

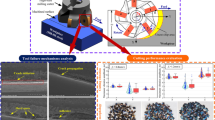

Tool steels are widely used in the plastics transformation industry, mainly as raw material to produce molds and dies. In this work, the influence of feed and rounding of the cutting tool edge in the machining of VP20TS steel will be investigated. For this, the wear of the cutting tool will be analyzed with the aid of optical microscopy, scanning electron microscopy, and energy-dispersive x-ray spectroscopy, the roughness of the machined surface will be evaluated through the parameter Ra, and the electric current required by the machine tool will be monitored by means of Hall effect sensors attached to the main power cables. The results obtained showed that the cutting tool wear was attenuated with the use of rβ = 0.03 mm, with adhesion being the predominant wear mechanism. The increase in feed influenced the decrease in wear. The machined surface roughness decreased when the tool with the highest cutting-edge radius value was used. Low-cost system used to monitor the electrical current required by the machine was sensitive to changes in feed and cutting-edge preparation. For higher values of feed and cutting-edge radius, higher values of electric current were required, indicating that edges prepared with larger values of radius generate greater cutting forces.

Similar content being viewed by others

Data availability

Not applicable.

References

Diniz AE, Marcondes FC, Coppini NL (2013) Tecnologia da Usinagem dos Materiais, 8a. Artliber, São Paulo (In portuguese)

Rodríguez CJC (2009) Cutting edge preparation of precision cutting tools by applying micro-abrasive jet machining and brushing, 1a. Kassel University Press, Kassel

Zhuang K, Fu C, Weng J, Hu C (2021) Cutting edge microgeometries in metal cutting: a review. Int J Adv Manuf Technol 116:2045–2092. https://doi.org/10.1007/s00170-021-07558-6

Agic A, Eynian M, Ståhl JE, Beno T (2019) Experimental analysis of cutting edge effects on vibrations in end milling. CIRP J Manuf Sci Technol 24:66–74. https://doi.org/10.1016/j.cirpj.2018.11.001

Kang Y, Derouach H, Berger N et al (2020) Experimental research of picosecond laser based edge preparation of cutting tools. J Laser Appl 32:022043. https://doi.org/10.2351/7.0000066

Peter P, Boris P, Tomáš V et al (2020) Cutting edge radius preparation. Mater Today Proc 22:212–218. https://doi.org/10.1016/j.matpr.2019.08.090

Zhou C, Guo K, Yang B et al (2019) Singularity analysis of cutting force and vibration for tool condition monitoring in milling. IEEE Access 7:134113–134124. https://doi.org/10.1109/ACCESS.2019.2941287

Vopát T, Kuruc M, Šimna V et al (2017) Cutting edge microgeometry and preparation methods. Proceedings of the 28th DAAAM International Symposium, B. Katalinic (Ed.), Published by DAAAM International, Vienna, Austria 384–391. https://doi.org/10.2507/28th.daaam.proceedings.054

Fulemova J, Janda Z (2014) Influence of the cutting edge radius and the cutting edge preparation on tool life and cutting forces at inserts with wiper geometry. Procedia Eng 69:565–573. https://doi.org/10.1016/j.proeng.2014.03.027

Aurich JC, Zimmermann M, Leitz L (2011) The preparation of cutting edges using a marking laser. Prod Eng Res Devel 5:17–24. https://doi.org/10.1007/s11740-010-0275-9

Li B, Zhang S, Yan Z, Zhang J (2017) Influence of edge hone radius on cutting forces, surface integrity, and surface oxidation in hard milling of AISI H13 steel. Int J Adv Manuf Technol 97:305–318. https://doi.org/10.1007/s00170-017-1292-z

Zhao T, Zhou JM, Bushlya V, Ståhl JE (2017) Effect of cutting edge radius on surface roughness and tool wear in hard turning of AISI 52100 steel. Int J Adv Manuf Technol 91:3611–3618. https://doi.org/10.1007/s00170-017-0065-z

Bakar HNA, Ghani JA, Che Haron CH (2020) Influence of rounded cutting-edge radius and machining parameters on surface roughness and tool wear in milling AISI H13 steel under dry and cryogenic machining. J Tribol 24:52–64

Feng Y, Hung TP, Lu YT et al (2019) Flank tool wear prediction of laser-assisted milling. J Manuf Process 43:292–299. https://doi.org/10.1016/j.jmapro.2019.05.008

Feng Y, Hung TP, Lu YT et al (2019) Surface roughness modeling in laser-assisted end milling of Inconel 718. Mach Sci Technol 23:650–668. https://doi.org/10.1080/10910344.2019.1575407

Villares M (2020) Technical Data - Aço VP20TS, pp 1–8. https://www.villaresmetals.com.br/pt/Produtos/Acos-Ferramenta/MoldesPlasticos/VP20TS . Accessed 13 Apr 2023

Otec (2017) The importance of cutting edge preparation edge rounding and polishing of cutting tools contents, pp 1–38. https://edeltec.com/wp-content/uploads/2017/05/EN-The-Importance-of-Cutting-Edge-Preparation_2016.pdf. Accessed 03 Mar 2023

Denkena B, Biermann D (2014) Cutting edge geometries. CIRP Ann Manuf Technol 63:631–653. https://doi.org/10.1016/j.cirp.2014.05.009

Ferraresi D (1970) Fundamentos da Usinagem dos Metais, 1a. Blucher, São Paulo (In portuguese)

Barbosa MGCB, Hassui A, de Oliveira PA (2021) Effect of cutting parameters and cutting edge preparation on milling of VP20TS steel. Int J Adv Manuf Technol 116:2929–2942. https://doi.org/10.1007/s00170-021-07654-7

Bouzakis K-D, Michailidis N, Skordaris G et al (2002) Effect of the cutting edge radius and its manufacturing procedure, on the milling performance of PVD coated cemented carbide inserts. Ann CIRP 51:6–9. https://doi.org/10.1016/S0007-8506(07)61466-8

Zahoor S, Mufti NA, Saleem MQ et al (2017) Effect of machine tool’s spindle forced vibrations on surface roughness, dimensional accuracy, and tool wear in vertical milling of AISI P20. Int J Adv Manuf Technol 89:3671–3679. https://doi.org/10.1007/s00170-016-9346-1

Agostinho OL, Rodrigues AC dos S, Lirani J (2014) Princípios de engenharia de fabricação: Tolerâncias, ajustes, desvios e análise de dimensões, 1a. Blucher, São Paulo (In portuguese)

Machado ÁR, Abrão AM, Coelho RT, Silva MB (2015) Teoria da Usinagem dos Materiais, 3a. Blucher, São Paulo (In portuguese)

Li B, Zhang S, Yan Z, Zhang J (2018) Effect of edge hone radius on chip formation and its microstructural characterization in hard milling of AISI H13 steel. Int J Adv Manuf Technol 97:305–318. https://doi.org/10.1007/s00170-018-1933-x

de Souza AJ (2004) Aplicação de Multisensores no Prognóstico da Vida da Ferramenta de Corte em Torneamento. Thesis, Federal University of Santa Catarina. http://repositorio.ufsc.br/xmlui/handle/123456789/88055. Accessed 13 Apr 2023

Stein JL, Shin K-C (1986) Current Monitoring of Field Controlled DC Spindle Drives. J Dyn Syst Meas Control 108:289–295. https://doi.org/10.1115/1.3143796

Stein JL, Wang C-H (1990) Analysis of power monitoring on AC induction drive systems. J Dyn Syst Meas Control 112:239–248. https://doi.org/10.1115/1.2896131

Braga DU (1992) Monitoramento do processo de Torneamento via Parâmetros Elétricos do Motor da Máquina. Master’s degree, University of Campinas. https://doi.org/10.47749/T/UNICAMP.1992.50773

Caldeirani Filho J (1998) Estudo e Monitoramento do Processo de Fresamento Frontal com Fresas de Insertos Intecambiáveis. Doctorate degree, University of Campinas. https://doi.org/10.47749/T/UNICAMP.1998.133526

Zhao X, Du Y, He L, Tao M (2019) Influence of edge preparation of coated carbide tool on milling aluminum alloy 211Z. J Braz Soc Mech Sci Eng 41:1–11. https://doi.org/10.1007/s40430-019-1611-4

Wyen C, Wegener K (2010) CIRP annals - manufacturing technology influence of cutting edge radius on cutting forces in machining titanium. CIRP Ann Manuf Technol 59:93–96. https://doi.org/10.1016/j.cirp.2010.03.056

Acknowledgements

The authors would like to thank Federal University of Piauí, CAPES, and Villares Metals.

Funding

This study was partly funded by the Federal University of Piauí (UFPI) and State University of Campinas (Unicamp) – grant reference 5102—FUNCAMP.

Author information

Authors and Affiliations

Contributions

M. Barbosa performed the experiments, analysis of results and manuscript writings; A. Hassui proposed the work topic and helped with results analysis; P. de Oliveira contributed to performed the experiments; W. Borges helped manuscript writings.

Corresponding author

Ethics declarations

Ethical approval

This study complied with the ethical standards set out by Springer.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Barbosa, M.G.C.B., Hassui, A., de Oliveira, P.A. et al. Influence of feed and cutting-edge radius on tool wear, surface roughness, and electric current in milling of VP20TS steel. Int J Adv Manuf Technol 129, 3609–3626 (2023). https://doi.org/10.1007/s00170-023-12526-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12526-3