Abstract

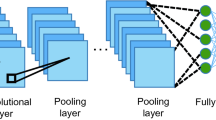

In many factories, production lines are rapidly expanding, and methods of signal acquisition are gaining more and more attention. Enterprises hope to establish control centers to monitor production information in real time. Melt viscosity is a very important key monitoring metric in plastic extrusion process. At present, the traditional extrusion industry mostly relies on the experience of thermometers, pressure gauges, and technicians to control the quality of manufacturing. This is not a good quality control scheme for scientific manufacturing. Thus, this project improves the signal acquisition structure by combining LoRa and Wi-Fi with heterogeneous IoT. Utilize soft sensing technology to provide more advanced signal measurements as the basis for intelligent manufacturing, including melt temperature and melt viscosity. According to the experimental results, the introduction of AMNT (Adaptive Model of Network Topology) algorithm, AMTP (Adaptive Model of Transmission Path) algorithm, and BNC (Butterfly Networking Coding) algorithm in heterogeneous IoT can optimize the transmission performance. Soft sensors based on random forests and convolutional neural networks can finally output melt characteristic scatter plot (viscosity, shear rate, and temperature).

Similar content being viewed by others

References

Barua A, Al Alamin MA, Hossain MS, Hossain E (2022) Security and privacy threats for bluetooth low energy in IoT and wearable devices: a comprehensive survey. IEEE Open J Commun Soc 3:251–281. https://doi.org/10.1109/OJCOMS.2022.3149732

Huang C, Liu H, Wang W, Li J (2020) A compact and cost-effective BLE beacon with multiprotocol and dynamic content advertising for IoT application. IEEE IoT J 7(3):2309–2320. https://doi.org/10.1109/JIOT.2019.2958455

Farha F, Ning H, Yang S, Xu J, Zhang W, Choo K-KR (2022) Timestamp scheme to mitigate replay attacks in secure Zigbee networks. IEEE Trans Mob Comput 21(1):342–351. https://doi.org/10.1109/TMC.2020.3006905

Pereira DS et al (2020) Zigbee protocol-based communication network for multi-unmanned aerial vehicle networks. IEEE Access 8:57762–57771. https://doi.org/10.1109/ACCESS.2020.2982402

Lee C-P, Lin P, Sung YC (2021) The module switching mechanism for power-constrained devices in LTE and NB-IoT interworking networks. IEEE Trans Veh Technol 70(2):2018–2023. https://doi.org/10.1109/TVT.2021.3050111

Leonardi L, Battaglia F, Patti G, Bello LL (2018) Industrial LoRa: a novel medium access strategy for LoRa in Industry 4.0 applications. IECON 2018 - 44th Annual Conference of the IEEE Industrial Electronics Society 4141–4146. https://doi.org/10.1109/IECON.2018.8591568

Wang Z-H, Shih S-T, Hendrick H, Pai M-Y, Horng G-J (2020) Deployment and evaluation of LoRa network configuration based on random forest. Int Comput Symp (ICS) 2020:262–265. https://doi.org/10.1109/ICS51289.2020.00059

Lombardo A, Parrino S, Peruzzi G, Pozzebon A (2022) LoRaWAN Versus NB-IoT: transmission performance analysis within critical environments. IEEE IoT Journal 9(2):1068–1081. https://doi.org/10.1109/JIOT.2021.3079567

Satam P, Hariri S (2021) WIDS: an anomaly based intrusion detection system for Wi-Fi (IEEE 802.11) protocol. IEEE Trans Netw Serv Manage 18(1):1077–1091. https://doi.org/10.1109/TNSM.2020.3036138

Willig A, Matheus K, Wolisz A (2005) Wireless technology in industrial networks. Proc IEEE 93(6):1130–1151. https://doi.org/10.1109/JPROC.2005.849717

Wan J, Yang J, Wang S, Li D, Li P, Xia M (2020) Cross-network fusion and scheduling for heterogeneous networks in smart factory. IEEE Trans Industr Inf 16(9):6059–6068. https://doi.org/10.1109/TII.2019.2952669

Xu L, Yin W, Zhang X, Yang Y (2020) Fairness-aware throughput maximization over cognitive heterogeneous NOMA networks for industrial cognitive IoT. IEEE Trans Commun 68(8):4723–4733. https://doi.org/10.1109/TCOMM.2020.2992720

Torroglosa-Garcia EM, Calero JMA, Bernabe JB, Skarmeta A (2020) Enabling roaming across heterogeneous IoT wireless networks: LoRaWAN MEETS 5G. IEEE Access 8:103164–103180. https://doi.org/10.1109/ACCESS.2020.2998416

Jiang Y, Yin S, Dong J, Kaynak O (2021) A review on soft sensors for monitoring, control, and optimization of industrial processes. IEEE Sensors J 21(11):12868–12881. https://doi.org/10.1109/JSEN.2020.3033153

Zong L, Memon FH, Li X, Wang H, Dev K (2022) End-to-end transmission control for cross-regional industrial iot in Industry 5.0. IEEE Trans Industr Inf 18(6):4215–4223. https://doi.org/10.1109/TII.2021.3133885

Hao WZ, Horng GJ, Jong GJ (2020) A new bio-inspired for cooperative data transmission of IoT. IEEE Access 8:161884–161893. https://doi.org/10.1109/ACCESS.2020.3021507

Malik S, Kim D (2020) A hybrid scheduling mechanism based on agent cooperation mechanism and fair emergency first in smart factory. IEEE Access 8:227064–227075. https://doi.org/10.1109/ACCESS.2020.3046097

Aziz B (2020) Modeling and analyzing an Industry 4.0 communication protocol. IEEE IoT Journal 7(10):10120–10127. https://doi.org/10.1109/JIOT.2020.2999325

Sinha D, Roy R (2020) Reviewing cyber-physical system as a part of smart factory in Industry 4.0. IEEE Eng Manag Rev 48(2):103–117. https://doi.org/10.1109/EMR.2020.2992606

Hsu C-W, Hsu Y-L, Wei H-Y (2020) Energy-efficient edge offloading in heterogeneous industrial IoT networks for factory of future. IEEE Access 8:183035–183050. https://doi.org/10.1109/ACCESS.2020.3029253

Mullet V, Sondi P, Ramat E (2021) A review of cybersecurity guidelines for manufacturing factories in Industry 4.0. IEEE Access 9:23235–23263. https://doi.org/10.1109/ACCESS.2021.3056650

Elijah O et al (2021) A survey on Industry 4.0 for the oil and gas industry: upstream sector. IEEE Access 9:144438–144468. https://doi.org/10.1109/ACCESS.2021.3121302

Garg S, Kaur K, Kaddoum G, Choo KR (2020) Toward secure and provable authentication for IoT: realizing Industry 4.0. IEEE IoT J 7(5):4598–4606. https://doi.org/10.1109/JIOT.2019.2942271

Zuo Y, Qi Z (2022) A blockchain-based IoT framework for oil field remote monitoring and control. IEEE Access 10:2497–2514. https://doi.org/10.1109/ACCESS.2021.3139582

Yao Y, Zhu Z, Huang S, Yue X, Pan C, Li X (2020) Energy efficiency characterization in heterogeneous IoT system with UAV swarms based on wireless power transfer. IEEE Access 8:967–979. https://doi.org/10.1109/ACCESS.2019.2961977

Wang ZH, Horng GJ, Gwo-Jia J (2021) A vehicle safety monitoring system based on the IoT and the identification of physiological characteristics. 2021 comput Electr Eng 89:106946. https://doi.org/10.1016/ISSN0045-7906

Ooi B-Y, Beh W-L, Lee W-K, Shirmohammadi S (2020) A parameter-free vibration analysis solution for legacy manufacturing machines’ operation tracking. IEEE IoT J 7(11):11092–11102. https://doi.org/10.1109/JIOT.2020.2994395

Lin HP, Jung CY, Huang TY et al (2020) NB-IoT application on decision support system of building information management. Wireless Pers Commun 114:711–729. https://doi.org/10.1007/s11277-020-07389-w

Bertoli L, Caltanissetta F, Colosimo BM (2021) In-situ quality monitoring of extrusion-based additive manufacturing via random forests and clustering. 2021 IEEE 17th International Conference on Automation Science and Engineering (CASE), 2057–2062. https://doi.org/10.1109/CASE49439.2021.9551654

Liu X, Li K, McAfee M, Deng J (2012) “Polymer extrusion process monitoring using nonlinear dynamic model-based PCA”, Proceedings of. UKACC Int Conf Control 2012:7–12. https://doi.org/10.1109/CONTROL.2012.6334593

Wang Z-H, Li Y-T, Wen F-C (2023) A novel in-line polymer melt viscosity sensing system of integrated soft sensor and machine learning. IEEE Sensors J 23(11):12181–12189. https://doi.org/10.1109/JSEN.2023.3267682

Wang Z-H (2023) A novel soft sensor approach of polymer process for resin monitoring based on melt pressure spectrum. IEEE Sensors J 23(15):17551–17558. https://doi.org/10.1109/JSEN.2023.3285106

Tsou H-H, Lee K-D, Wang Z-H, Huang C-C (2020) The feature extraction modeling of product analysis in injection molding for intelligent manufacturing. Int Comput Symp (ICS) 2020:325–329. https://doi.org/10.1109/ICS51289.2020.00071

Wang Z-H, Wen F-C, Li Y-T, Tsou H-H (2023) A novel sensing feature extraction based on mold temperature and melt pressure for plastic injection molding quality assessment. IEEE Sensors J 23(7):7451–7459. https://doi.org/10.1109/JSEN.2023.3247597

Jong GJ, Wang ZH, Hsieh KS, Horng GJ (2019) A novel adaptive optimization of intragrated network topology and transmission path for IoT system. IEEE Sensors J 19(15):6452–6459. https://doi.org/10.1109/JSEN.2019.2908702

Wang ZH, Kung YF, Cheng PJ, Wang CM, Jong GJ (2018) Enhance wireless security system using Butterfly Network Coding algorithm. 2018 International Conference on Applied Information Technology and Innovation (ICAITI), 135–138. https://doi.org/10.1109/ICAITI.2018.8686731

Funding

This work was supported by the grants from the Teaching Practice Research Program, Grant No. PSK1122933 and the Southern Taiwan University of Science and Technology (STUST) of the Higher Education Sprout Project by the Ministry of Education (MOE) in Taiwan.

Author information

Authors and Affiliations

Contributions

Z-HW: conceptualization, data curation, formal analysis, funding acquisition, investigation, methodology, project administration, resources, and writing—original draft; Y-TL: software, supervision, and validation; and Y-CW: visualization and writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, ZH., Li, YT. & Wu, YC. Design of intelligent manufacturing IoT sensing system for polymer process monitoring. Int J Adv Manuf Technol 129, 2933–2947 (2023). https://doi.org/10.1007/s00170-023-12510-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12510-x