Abstract

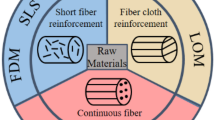

Additive manufacturing of polymers is used for rapid prototyping and in specific applications for the fabrication of final products. As the application range grows to the industrial sector, functional parts require better mechanical properties and tighter tolerance ranges. Short-fiber reinforced polymers can handle higher stresses and significantly less deformation than raw AM polymers, but their surface roughness and viscoelastic behavior are poorly understood. The authors perform the dynamical mechanical analysis, line, and surface roughness characterization of fused filament fabricated composites in this work. Mainly, Onyx, a short carbon-filled fiber nylon thermoplastic composite, was used in three different build orientations: flat, on-edge, and upright. Then, the effect of build orientation on the viscoelastic and roughness properties is discussed. Results showed that despite using the same raw material, printing direction has a moderate impact on the viscoelastic behavior and a significant effect on the surface roughness of the part. For instance, a difference of 25 °C in the Tg was observed between the on-edge and upright build orientation, with the latter the highest. Also, the flat print orientation presented the lowest values in the z-roughness of all the three build orientations analyzed.

Similar content being viewed by others

References

Palić N, Slavković V, Jovanović Ž, Živić F, Grujović N (2019) Mechanical behaviour of small load bearing structures fabricated by 3d printing,. Appl Eng Lett 4(3):88–92. https://doi.org/10.18485/aeletters.2019.4.3.2

Mercado Rivera FJ, Rojas Arciniegas AJ (2020) Additive manufacturing methods: techniques, materials, and closed-loop control applications,. Int J Adv Manuf Technol 109(1–2):17–31. https://doi.org/10.1007/s00170-020-05663-6

Hoa S, Reddy B (2021) Rosca D (2021) “Development of omega stiffeners using 4D printing of composites,.” Compos Struct 272:114264. https://doi.org/10.1016/j.compstruct.2021.114264.

Yu Y et al (2020) Material characterization and precise finite element analysis of fiber reinforced thermoplastic composites for 4D printing,. CAD Comput Aided Des 122:102817. https://doi.org/10.1016/j.cad.2020.102817

Juan León B, Díaz-Rodríguez JG, González-Estrada OA (2020) Daño en partes de manufactura aditiva reforzadas por fibras continuas,. Revista UIS Ingenierías 19(2):161–175. https://doi.org/10.18273/revuin.v19n2-2020018

Heidari-Rarani M, Rafiee-Afarani M, Zahedi AM (2019) Mechanical characterization of FDM 3D printing of continuous carbon fiber reinforced PLA composites Compos B Eng 175 https://doi.org/10.1016/j.compositesb.2019.107147

León-Becerra JS, González-Estrada OA (2020) W Pinto-Hernández, “Mechanical characterization of additive manufacturing composite parts,.” Respuestas 25:2. https://doi.org/10.22463/0122820x.2189

Leon-Becerra J, González-Estrada OA, Sánchez-Acevedo H (2022) Comparison of models to predict mechanical properties of FR-AM composites and a fractographical study,. Polymers (Basel) 14(17):3546. https://doi.org/10.3390/polym14173546

Mohammadizadeh M, Fidan I (2020) “Experimental evaluation of additively manufactured continuous fiber reinforced nylon composites,” Minerals Metals and Materials Series 321–328 https://doi.org/10.1007/978-3-030-36296-6_30

Chacón JM, Caminero MA, Núñez PJ, García-Plaza E, García-Moreno I, Reverte JM (2019) Additive manufacturing of continuous fibre reinforced thermoplastic composites using fused deposition modelling: effect of process parameters on mechanical properties. Compos Sci Technol 181 https://doi.org/10.1016/j.compscitech.2019.107688

Nugroho A, Ardiansyah R, Rusita L, Larasati IL (2018) Effect of layer thickness on flexural properties of PLA (PolyLactid Acid) by 3D printing,. J Phys Conf Ser 1130:1. https://doi.org/10.1088/1742-6596/1130/1/012017

Anoop MS, Senthil P, Sooraj VS (2021) An investigation on viscoelastic characteristics of 3D-printed FDM components using RVE numerical analysis,. J Braz Soc Mech Sci Eng 43:1. https://doi.org/10.1007/s40430-020-02724-5

Edelen DL, Bruck HA (2022) Predicting failure modes of 3D-printed multi-material polymer sandwich structures from process parameters,. J Sandwich Struct Mater 24(2):1049–1075. https://doi.org/10.1177/10996362211020445

Jin Y et al (2020) Novel 2D dynamic elasticity maps for inspection of anisotropic properties in fused deposition modeling objects,. Polym (Basel) 12:9. https://doi.org/10.3390/polym12091966

Díaz JG, León-Becerra J, Pertuz AD, González-Estrada OA, Jaramillo-Gutiérrez MI (2021) Evaluation through SEM image processing of the volumetric fiber content in continuos fiber-reinforced additive manufacturing composites,. Mater Res 24:2. https://doi.org/10.1590/1980-5373-mr-2022-0049

Mohammadizadeh M, Fidan I, Allen M, Imeri A (2018) Creep behavior analysis of additively manufactured fiber-reinforced components,. Int J Adv Manuf Technol 99(5–8):1225–1234. https://doi.org/10.1007/s00170-018-2539-z

Mohammadizadeh M, Gupta A, Fidan I (2021) Mechanical benchmarking of additively manufactured continuous and short carbon fiber reinforced nylon,. J Compos Mater 55(25):3629–3638. https://doi.org/10.1177/00219983211020070

Calignano F, Lorusso M, Roppolo I, Minetola P (2020) Investigation of the mechanical properties of a carbon fibre-reinforced nylon filament for 3d printing,. Machines 8(3):1–13. https://doi.org/10.3390/machines8030052

León-Becerra J, González-Estrada OA, Quiroga J (2021) Effect of relative density in in-plane mechanical properties of common 3D-printed polylactic acid lattice structures,. ACS Omega 6(44):29830–29838. https://doi.org/10.1021/acsomega.1c04295

Reverte JM, Ángel Caminero M, Chacón JM, García-Plaza E, Núñez PJ, Becar JP (2020) Mechanical and geometric performance of PLA-based polymer composites processed by the fused filament fabrication additive manufacturing technique,. Materials 13:8. https://doi.org/10.3390/MA13081924

Türk DA, Brenni F, Zogg M, Meboldt M (2017) Mechanical characterization of 3D printed polymers for fiber reinforced polymers processing,. Mater Des 118:256–265. https://doi.org/10.1016/j.matdes.2017.01.050

Mohamed OA, Masood SH, Bhowmik JL (2016) “Analytical modelling and optimization of the temperature-dependent dynamic mechanical properties of fused deposition fabricated parts made of PC-ABS,” Materials 9 11https://doi.org/10.3390/ma9110895

Blanco I, Siracusa V (2021) The use of thermal techniques in the characterization of bio-sourced polymers,. Materials 14:7. https://doi.org/10.3390/ma14071686

Zander NE, Park JH, Boelter ZR, Gillan MA (2019) Recycled cellulose polypropylene composite feedstocks for material extrusion additive manufacturing,. ACS Omega 4(9):13879–13888. https://doi.org/10.1021/acsomega.9b01564

Coppola B, Cappetti N, di Maio L, Scarfato P, Incarnato L (2018) 3D printing of PLA/clay nanocomposites: influence of printing temperature on printed samples properties,. Materials 11:10. https://doi.org/10.3390/ma11101947

Mazurchevici SN, Mazurchevici AD, Nedelcu D (2020) Dynamical mechanical and thermal analyses of biodegradable raw materials for additive manufacturing,. Materials 13:8. https://doi.org/10.3390/MA13081819

Galeja M, Hejna A, Kosmela P, Kulawik A (2020) Static and dynamic mechanical properties of 3D printed ABS as a function of raster angle,. Materials 13:2. https://doi.org/10.3390/ma13020297

Billah KMM, Lorenzana FAR, Martinez NL, Wicker RB, Espalin D (2020) “Thermomechanical characterization of short carbon fiber and short glass fiber-reinforced ABS used in large format additive manufacturing,” Addit Manuf 35 https://doi.org/10.1016/j.addma.2020.101299

Cannella F, Garinei A, Marsili R, Speranzini E (2018) Dynamic mechanical analysis and thermoelasticity for investigating composite structural elements made with additive manufacturing,. Compos Struct 185:466–473. https://doi.org/10.1016/j.compstruct.2017.11.029

Abayazid FF, Ghajari M (2020) “Material characterisation of additively manufactured elastomers at different strain rates and build orientations,” Addit Manuf 33 https://doi.org/10.1016/j.addma.2020.101160

Robinson M et al (2018) Mechanical characterisation of additively manufactured elastomeric structures for variable strain rate applications,. Addit Manuf 27:398–407. https://doi.org/10.1016/j.addma.2019.03.022

Webster S, Lin H, Carter FM III, Ehmann K, Cao J (2021) Physical mechanisms in hybrid additive manufacturing: a process design framework,. J Mater Process Technol 291:117048. https://doi.org/10.1016/j.jmatprotec.2021.117048

Iragi M, Pascual-González C, Esnaola A, Lopes CS, Aretxabaleta L (2019) “Ply and interlaminar behaviours of 3D printed continuous carbon fibre-reinforced thermoplastic laminates; effects of processing conditions and microstructure,” Addit Manuf 30 https://doi.org/10.1016/j.addma.2019.100884

YeJ Yao T, Deng Z, Zhang K, Dai S, Liu X (2021) A modified creep model of polylactic acid (PLA-max) materials with different printing angles processed by fused filament fabrication,. J Appl Polym Sci 138:17. https://doi.org/10.1002/app.50270

Fernandes RR, Tamijani AY, Al-Haik M (2021) “Mechanical characterization of additively manufactured fiber-reinforced composites,” Aerosp Sci Technol 113 https://doi.org/10.1016/j.ast.2021.106653

Zhao J, Perkins E, Li XF, Bond A, Marghitu D (2021) Nonlinear vibratory properties of additive manufactured continuous carbon fiber reinforced polymer composites,. Int J Adv Manuf Technol 117(3–4):1077–1089. https://doi.org/10.1007/s00170-021-07456-x

Pascual-González C, Iragi M, Fernández A, Fernández-Blázquez JP, Aretxabaleta L, Lopes CS (2020) “An approach to analyse the factors behind the micromechanical response of 3D-printed composites,” Compos B Eng 186 https://doi.org/10.1016/j.compositesb.2020.107820

García E, Núñez PJ, Chacón JM, Caminero MA, Kamarthi S (2020) Comparative study of geometric properties of unreinforced PLA and PLA-Graphene composite materials applied to additive manufacturing using FFF technology. Polym Test 91 https://doi.org/10.1016/j.polymertesting.2020.106860

Caminero MÁ, Chacón JM, García-Plaza E, Núñez PJ, Reverte JM, Becar JP (2019) Additive manufacturing of PLA-based composites using fused filament fabrication: effect of graphene nanoplatelet reinforcement on mechanical properties, dimensional accuracy and texture,. Polymers (Basel) 11:5. https://doi.org/10.3390/polym11050799

UNE-EN ISO 4287 (1999) “Especificación geométrica de productos. Calidad superficial: Método del perfil. Términos, definiciones y parámetros del estado superficial

Klata E, van de Velde K, Krucińska I (2003) DSC investigations of polyamide 6 in hybrid GF/PA 6 yarns and composites,. Polym Test 22(8):929–937. https://doi.org/10.1016/S0142-9418(03)00043-6

Díaz-Rodríguez JG, Pertúz-Comas AD, González-Estrada OA (2021) Mechanical properties for long fibre reinforced fused deposition manufactured composites,. Compos B Eng 211:108657. https://doi.org/10.1016/j.compositesb.2021.108657

Menard KP, Menard NR (2020) Dynamic Mechanical Analysis, 3rd edn. CRC Press, Boca Raton, FL

al Rashid A, Koҫ M, (2021) Creep and recovery behavior of continuous fiber-reinforced 3DP composites,. Polymers (Basel) 13(10):1644. https://doi.org/10.3390/polym13101644

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

León-Becerra, J., Hidalgo-Salazar, M.Á., Correa-Aguirre, J.P. et al. Additive manufacturing of short carbon filled fiber nylon: effect of build orientation on surface roughness and viscoelastic behavior. Int J Adv Manuf Technol 130, 425–435 (2024). https://doi.org/10.1007/s00170-023-12503-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12503-w