Abstract

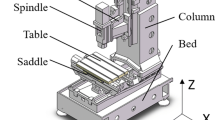

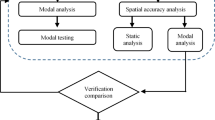

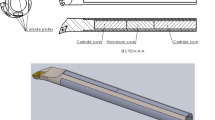

In order to enhance the accuracy and productivity of CNC machine tools, the finite element method (FEM) is utilized for analyzing machining operations and machine tool structures. Through this approach, it becomes possible to assess and reduce machining errors, thereby improving the precision of machined parts. Additionally, by subjecting machine tool components to the analysis of stress and deformations under real operating conditions, the overall performance and lifespan of the machine tool structures can be augmented. This study focuses on the implementation of finite element methods for the analysis and optimization of CNC machine tool operations and structure. In this study, a virtual model of the Good Way CNC turning machine was used to study the machine’s behavior. The first three vibrational modes analyzed through a modal analysis were 108.2 Hz, 133.4 Hz, and 191.7 Hz, which were experimentally validated using modal tests. The design precision was supported by the harmonic response. For an applied external load of 500 N on the head chuck, the tool turret's transient response was established through transient analysis at 0.4 s. However, after the static analysis, the maximum deformation of the machine at the same external applied load on the tool turret was upheld at 7.6 μm. The spatial position analysis rectified the modal performance of the machine at a variety of set working positions. As the principal cause of rigidity originates from the base of the machine, three sets of ground support combinations were claimed to test the machine's rigidity. After the topology optimization analysis was achieved, a better-optimized version of the design was suggested. The old and new models were compared, and an increase of 1.5% in the first three modal frequencies was observed.

Similar content being viewed by others

Abbreviations

- m :

-

mass of the system (kg)

- k :

-

stiffness coefficient (N/m)

- c :

-

damping coefficient (Ns/m)

- ω :

-

angular frequency (rad/s)

- f(t):

-

applied force as a function of time (N)

- u(t):

-

displacement as a function of time (m)

- x(f):

-

frequency domain representation of displacement (m/Hz)

- Φ:

-

mode shape vector

References

Kurowski PM (2022) Finite element analysis for design engineers. SAE International. https://doi.org/10.4271/R-449

Doyle R, Case K (1990) CAE software in manufacturing engineering education. Computer Assisted Learning. Pergamon, pp 277-288. https://doi.org/10.1016/B978-0-08-040249-9.50043-X

Zaeh M, Siedl D (2007) A new method for simulation of machining performance by integrating finite element and multi-body simulation for machine tools. CIRP Ann 56(1):383–386. https://doi.org/10.1016/j.cirp.2007.05.089

Mackerle J (1999) Finite-element analysis and simulation of machining: a bibliography (1976–1996). J Mater Process Technol 86(1-3):17–44. https://doi.org/10.1016/S0924-0136(98)00227-1

Zaghbani I, Songmene V (2009) Estimation of machine-tool dynamic parameters during machining operation through operational modal analysis. Int J Mach Tool Manuf 49(12-13):947–957. https://doi.org/10.1016/j.ijmachtools.2009.06.010

Besharati SR et al (2016) Multi-objective selection and structural optimization of the gantry in a gantry machine tool for improving static, dynamic, and weight and cost performance. Concurr Eng 24(1):83–93. https://doi.org/10.1177/1063293X15597047

Tunc LT, Mohammadi Y, Budak E (2018) Destabilizing effect of low frequency modes on process damped stability of multi-mode milling systems. Mech Syst Signal Process 111:423–441. https://doi.org/10.1016/j.ymssp.2018.03.051

Chan TC, Lin HH, Reddy SV (2022) Prediction model of machining surface roughness for five-axis machine tool based on machine-tool structure performance. Int J Adv Manuf Technol 120(1-2):237–249. https://doi.org/10.1007/s00170-021-08634-7

Chan TC et al (2022) Simulation, modeling, and experimental verification of moving column precision grinding machine. J Chin Inst Eng 45(1):54–64. https://doi.org/10.1080/02533839.2021.1983464

Mbarek A et al (2018) Comparison of experimental and operational modal analysis on a back to back planetary gear. Mech Mach Theory 124:226–247. https://doi.org/10.1016/j.mechmachtheory.2018.03.005

Yang B et al (2019) Kinematic modeling and machining precision analysis of multi-axis CNC machine tools based on screw theory. Mech Mach Theory 140:538–552. https://doi.org/10.1016/j.mechmachtheory.2019.06.021

Wang M et al (2022) Dimensional parameters and structural topology integrated design method of a planar 5R parallel machining robot. Mech Mach Theory 175:104964. https://doi.org/10.1016/j.mechmachtheory.2022.104964

Chauhan S et al (2011) Operational modal analysis of operating wind turbines: application to measured data. Rotating Machinery, Structural Health Monitoring, Shock and Vibration, Volume 5: Proceedings of the 29th IMAC, A Conference on Structural Dynamics, 2011 pp (65-81). New York, NY: Springer New York. https://doi.org/10.1007/978-1-4419-9428-8_6

Chen D, Fan J, Zhang F (2012) Dynamic and static characteristics of a hydrostatic spindle for machine tools. J Manuf Syst 31(1):26–33. https://doi.org/10.1016/j.jmsy.2010.11.006

Wu Z et al (2010) Modal and harmonic response analysis and evaluation of machine tools. 2010 International Conference on Digital Manufacturing & Automation. Vol. 1, pp 929-933 IEEE. https://doi.org/10.1109/ICDMA.2010.155

Lu X, Chen Y, Sheng X (2022) Analysis of the influence of structural parameters on the modes of a gantry machine tool crossbeam based on analytical method. Appl Sci 12(21):11083. https://doi.org/10.3390/app122111083

Chan TC, Yang JS (2020) Optimized design and performance study of high speed five-axis machine tools. In: International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, vol 83952. American Society of Mechanical Engineers. https://doi.org/10.1115/DETC2020-22253

Hong CC, Chang CL, Lin CY (2016) Static structural analysis of great five-axis turning–milling complex CNC machine. Eng Sci Technol 19(4):1971–1984. https://doi.org/10.1016/j.jestch.2016.07.013

Chan TC et al (2023) Study on kinematic structure performance and machining characteristics of 3-axis machining center. Appl Sci 13(8):4742. https://doi.org/10.3390/app13084742

Huo D, Cheng J, Wardle F (2010) Design of a five-axis ultra-precision micro-milling machine—UltraMill. Part 1: holistic design approach, design considerations and specifications. Int J Adv Manuf Technol 47:867–877. https://doi.org/10.1007/s00170-009-2129-1

Li X et al (2021) Structural design and optimization of the crossbeam of a computer numerical controlled milling-machine tool using sensitivity theory and NSGA-II algorithm. Int J Precis Eng Manuf 22:287–300. https://doi.org/10.1007/s12541-020-00435-4

Deng C et al (2015) Dynamic characteristics optimization for a whole vertical machining center based on the configuration of joint stiffness. Int J Adv Manuf Technol 76:1225–1242. https://doi.org/10.1007/s00170-014-6355-9

Qiu L et al (2022) Research on the line-arc-line constant-torque flexure hinge (LAL-CTFH) based on improved pseudo-rigid-body model (PRBM). Mech Mach Theory 174:104878. https://doi.org/10.1016/j.mechmachtheory.2022.104878

Ji Q et al (2020) Structural design optimization of moving component in CNC machine tool for energy saving. J Clean Prod 246:118976. https://doi.org/10.1016/j.jclepro.2019.118976

Zhong G et al (2018) Design optimization approach of a large-scale moving framework for a large 5-axis machining center. Appl Sci 8(9):1598. https://doi.org/10.3390/app8091598

Park HW, Park YB, Steven Y. Liang (2011) Multi-procedure design optimization and analysis of mesoscale machine tools. Int J Adv Manuf Technol 56: 1-12. https://doi.org/10.1007/s00170-011-3160-6

Wang KC, Yang CH (2023) Structural design optimization of movable-column horizontal machining center based on integral stiffness analysis and sensor measurement. Sens Mater 35:10.18494/SAM4117

Ibrahim AM, Ali AM, Kamel H (2023) Design optimization and production of a small-scale semi-trailer chassis for testing. J Eng Appl Sci 70(1):35. https://doi.org/10.1186/s44147-023-00201-z

Zienkiewicz OC, Morice PBFF (1971) The finite element method in engineering science, vol 1977. McGraw-hill, London https://lccn.loc.gov/76028984

Bathe KJ, Wilson EL (1976) Numerical methods in finite element analysis. (No Title). https://lccn.loc.gov/75046522

White DA et al (2023) A reduced order model approach for finite element analysis of cellular structures. Finite Elem Anal Des 214:103855. https://doi.org/10.1016/j.finel.2022.103855

Gil J et al (2022) Finite element periodic catenary model to perform HIL pantograph tests considering non-linear dropper behaviour. Finite Elem Anal Des 210:103816. https://doi.org/10.1016/j.finel.2022.103816

Tlusty J, Ismail F (1983) Special aspects of chatter in milling:24–32. https://doi.org/10.1115/1.3269061

Bais RS et al (2004) Studies in dynamic design of drilling machine using updated finite element models. Mech Mach Theory 39(12):1307–1320. https://doi.org/10.1016/j.mechmachtheory.2004.05.022

Schwarz BJ, Richardson MH (1999) Experimental modal analysis. CSI Reliability Week 35(1):1–12

Gao DQ et al (2011) Finite element analysis and structure optimization of machine tool worktable. Appl Mech Mater 80:985–989. https://doi.org/10.4028/www.scientific.net/AMM.80-81.985

Woytowitz PJ, Hight TK (1994) Optimization of controlled flexible mechanisms using dynamic nonlinear finite element analysis. Mech Mach Theory 29(7):941–958. https://doi.org/10.1016/0094-114X(94)90063-9

Cheng YH, Chen YC (2022) Design, analysis, and optimization of a strain wave gear with a novel tooth profile. Mech Mach Theory 175:104953. https://doi.org/10.1016/j.mechmachtheory.2022.104953

Yakoub RY, Shabana AA (2001) Three dimensional absolute nodal coordinate formulation for beam elements: implementation and applications. J Mech Des 123(4):614–621. https://doi.org/10.1115/1.1410099

Shabana A, Yakoub RY (2001) Three dimensional absolute nodal coordinate formulation for beam elements: theory. J Mech Des 123(4):606–613. https://doi.org/10.1115/1.1410100

Tian Q et al (2009) An efficient hybrid method for multibody dynamics simulation based on absolute nodal coordinate formulation:021009. https://doi.org/10.1115/1.3079783

Gerstmayr J, Irschik H (2008) On the correct representation of bending and axial deformation in the absolute nodal coordinate formulation with an elastic line approach. J Sound Vib 318(3):461–487. https://doi.org/10.1016/j.jsv.2008.04.019

García-Vallejo D et al (2004) Efficient evaluation of the elastic forces and the Jacobian in the absolute nodal coordinate formulation. Nonlinear Dyn 35:313–329. https://doi.org/10.1023/B:NODY.0000027747.41604.20

Torstenfelt B, Klarbring A (2007) Conceptual optimal design of modular car product families using simultaneous size, shape, and topology optimization. Finite Elem Anal Des 43(14):1050–1061. https://doi.org/10.1016/j.finel.2007.06.005

Acknowledgements

The authors are indebted to the National Science and Technology Council (Grant numbers: 111-2221-E-150-024-MY2 and 111-2622-E-150-009).

Author information

Authors and Affiliations

Contributions

Experiment: S. Reddy. Analysis: Aman U and S. Reddy. Methodology: T.-C. Chan and S. Reddy. Validation: S. Reddy. Original draft preparation: Aman U, S. Reddy, and B. Roy. Supervision: T.-C. Chan.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chan, TC., Reddy, S.V.V.S., Ullah, A. et al. Effect of spatial moving structure and topology optimization of the CNC turning machine tools. Int J Adv Manuf Technol 129, 2969–2987 (2023). https://doi.org/10.1007/s00170-023-12500-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12500-z