Abstract

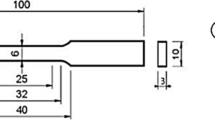

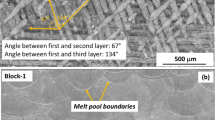

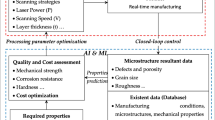

Metal additive manufacturing (AM) has become a widely adopted technique in various industries, owing to its flexible free-form manufacturing capabilities. M300 steel is widely applicable in industrial applications due to its exceptional mechanical properties, including superior strength and toughness. This study explores the effects of three selective laser melting (SLM) parameters—laser power, laser speed, and hatching distance—on M300 steel’s hardness, surface roughness, elongation, and ultimate tensile strength (UTS). Microhardness findings reveal higher values at the sample edges compared to the center. Surface roughness analysis shows irregular patterns of roughness at different direction with the minimum roughness along the building direction. The combination of maximum UTS of 1078 MPa and elongation of 0.12% is obtained in this study. Statistical analysis identified laser power the most significant parameter on the roughness value with 52.2% contribution. In contrast, laser power minimally affects UTS (0.69%), while hatch distance dominates with a 59.10% contribution. Response surface methodology (RSM) highlights that reducing hatch distance and laser power increases UTS and decreases roughness. However, decreasing laser speed raises UTS but significantly increases surface roughness. Finally, a regression model enables UTS prediction for samples. This study enhanced the understanding of how SLM parameters affects M300 steel mechanical characteristics, facilitating decisions in SLM processes.

Similar content being viewed by others

References

Galantucci LM, Guerra MG, Dassisti M, Lavecchia F (2019) Additive manufacturing: new trends in the 4th Industrial Revolution. In: International Conference on the Industry 4.0 model for Advanced Manufacturing. Springer, pp 153–169

Zadi-Maad A, Rohib R, Irawan A (2018) Additive manufacturing for steels: a review. In: IOP Conference Series: Materials Science and Engineering, vol 285. IOP Publishing, p 012028

Lee J-Y et al (2016) The potential to enhance membrane module design with 3D printing technology. J Membr Sci 499:480–490

Xu X, Ganguly S, Ding J, Guo S, Williams S, Martina F (2018) Microstructural evolution and mechanical properties of maraging steel produced by wire + arc additive manufacture process. Mater Charact 143:152–162

Mutua J, Nakata S, Onda T, Chen Z-C (2018) Optimization of selective laser melting parameters and influence of post heat treatment on microstructure and mechanical properties of maraging steel. Mater Des 139:486–497

Mugwagwa L, Yadroitsev I, Matope S (2019) Effect of process parameters on residual stresses, distortions, and porosity in selective laser melting of maraging steel 300. Metals 9(10):1042

Becker TH, Dimitrov D (2016) The achievable mechanical properties of SLM produced Maraging Steel 300 components. Rapid Prototyp J 22(3):487–494

de Souza AF, Al-Rubaie KS, Marques S, Zluhan B, Santos EC (2019) Effect of laser speed, layer thickness, and part position on the mechanical properties of maraging 300 parts manufactured by selective laser melting. Mater Sci Eng A 767:138425

Vishwakarma J, Chattopadhyay K, Srinivas NS (2020) Effect of build orientation on microstructure and tensile behaviour of selectively laser melted M300 maraging steel. Mater Sci Eng A 798:140130

Mooney B, Kourousis KI, Raghavendra R (2019) Plastic anisotropy of additively manufactured maraging steel: influence of the build orientation and heat treatments. Addit Manuf 25:19–31

Kempen K, Yasa E, Thijs L, Kruth J-P, Van Humbeeck J (2011) Microstructure and mechanical properties of Selective Laser Melted 18Ni-300 steel. Phys Procedia 12:255–263

Bhardwaj T, Shukla M (2018) Effect of laser scanning strategies on texture, physical and mechanical properties of laser sintered maraging steel. Mater Sci Eng A 734:102–109

Casalino G, Campanelli S, Contuzzi N, Ludovico A (2015) Experimental investigation and statistical optimisation of the selective laser melting process of a maraging steel. Opt Laser Technol 65:151–158

Suryawanshi J, Prashanth K, Ramamurty U (2017) Tensile, fracture, and fatigue crack growth properties of a 3D printed maraging steel through selective laser melting. J Alloys Compd 725:355–364

Ahmadkhaniha D, Möller H, Zanella C (2021) Studying the microstructural effect of selective laser melting and electropolishing on the performance of maraging steel. J Mater Eng Perform 30(9):6588–6605

Apparao D, Jagannadha Raju M (2018) Experimental investigation on hardness, microstructure and surface roughness of maraging steel parts produced by direct metal laser sintering technique. Int J Mech Prod Eng Res Dev (IJMPERD) 8(2):629–636

Duval-Chaneac M, Han S, Claudin C, Salvatore F, Bajolet J, Rech J (2018) Experimental study on finishing of internal laser melting (SLM) surface with abrasive flow machining (AFM). Precis Eng 54:1–6

Bhardwaj T, Shukla M (2018) Direct metal laser sintering of maraging steel: effect of building orientation on surface roughness and microhardness. Materials Today: Proceedings 5(9):20485–20491

Parvinzadeh M, Sattarpanah Karganroudi S, Omidi N, Barka N, Khalifa M (2021) A novel investigation into the edge effect reduction of 4340 steel disc through induction hardening process using magnetic flux concentrators. Int J Adv Manuf Technol 115(9):2959–2971

Parvinzadeh M, Sattarpanah Karganroudi S, Omidi N, Barka N, Khalifa M (2021) A novel investigation into edge effect reduction of 4340 steel spur gear during induction hardening process. Int J Adv Manuf Technol 113(1):605–619

Delgado J, Ciurana J, Rodríguez CA (2012) Influence of process parameters on part quality and mechanical properties for DMLS and SLM with iron-based materials. Int J Adv Manuf Technol 60(5):601–610

Zhang S, Rauniyar S, Shrestha S, Ward A, Chou K (2019) An experimental study of tensile property variability in selective laser melting. J Manuf Process 43:26–35

Mao Z, Lu X, Yang H, Niu X, Zhang L, Xie X (2022) Processing optimization, microstructure, mechanical properties and nanoprecipitation behavior of 18Ni300 maraging steel in selective laser melting. Mater Sci Eng A 830:142334

Kardak A, Bilich L, Sinclair G (2017) Stress concentration factors for ASTM E8/E8M-15a plate-type specimens for tension testing. J Test Eval 45(6):2294–2298

Scheiner SM, Gurevitch J (2001) Design and analysis of ecological experiments. Oxford University Press

Miller RG Jr (1997) Beyond ANOVA: basics of applied statistics. CRC press

“<Masterthesiswork-PariaKN-2016-06-13.pdf>”. https://doi.org/10.13140/RG.2.2.25434.64963.

Yasa E, Kempen K, Kruth J-P (2010) Microstructure and mechanical properties of maraging steel 300 after selective laser melting. In: 2010 International Solid Freeform Fabrication Symposium. University of Texas at Austin

Lei F , Wen T, Yang H, Fu J, Wang J (n.d.) Microstructures and mechanical properties of H13 tool steel processed by selective laser melting,” Hailin and Fu, Junwei and Wang, Jiong and ji, shouxun, Microstructures and mechanical properties of H13 tool steel processed by selective laser melting

Conde F, Avila J, Oliveira J, Schell N, Oliveira M, Escobar J (2021) Effect of the as-built microstructure on the martensite to austenite transformation in a 18Ni maraging steel after laser-based powder bed fusion. Addit Manuf 46:102122

Chakravarthi K, Koundinya N, Murty SN, Rao BN (2018) Microstructure, properties and hot workability of M300 grade maraging steel. Defence technology 14(1):51–58

Rońda N, Grzelak K, Polański M, Dworecka-Wójcik J (2022) The influence of layer thickness on the microstructure and mechanical properties of M300 maraging steel additively manufactured by LENS® Technology. Materials 15(2):603

Król M, Snopiński P, Hajnyš J, Pagáč M, Łukowiec D (2020) Selective laser melting of 18NI-300 maraging steel. Materials 13(19):4268

Bai Y, Yang Y, Wang D, Zhang M (2017) Influence mechanism of parameters process and mechanical properties evolution mechanism of maraging steel 300 by selective laser melting. Mater Sci Eng A 703:116–123

Funding

The authors declare that the research presented in this paper did not receive any external funding or financial support. This research was conducted independently without any financial contributions from grants, institutions, or organizations.

Author information

Authors and Affiliations

Contributions

Narges Omidi: data curation, writing—original draft preparation, conceptualization, methodology; Pedram Farhadipour: software, validation and editing, experiments; Noureddine Barka: editing, supervision

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Omidi, N., Farhadipour, P. & Barka, N. Investigation into the effect of the SLM processing parameters on the microstructure and mechanical behavior of M300; experimental and statistical analysis. Int J Adv Manuf Technol 129, 4419–4434 (2023). https://doi.org/10.1007/s00170-023-12495-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12495-7