Abstract

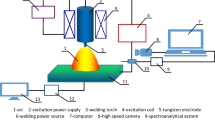

In order to realize the heat input regulation in the gas tungsten arc welding (GTAW) process, a novel compound excitation device consisting of a longitudinal magnetic field and a cusp magnetic field was developed in this paper. The magnetic field distribution law in the arc zone was analyzed under various excitation parameters of the device. Using 316L austenitic stainless steel as the base metal, the variation law of arc and weld penetration under different coupling excitation parameters was studied. The research reveals that the magnetic induction intensity in arc zone approximately conforms to the linear superposition law of two single magnetic fields. Under the compound excitation device, the welding arc is compressed while maintaining its deflection, causing its cross-section to change from circular to elliptical. Under the premise that the longitudinal excitation current maintains the arc deflection angle, an increase in cusp excitation current results in a decrease in weld width and arc bottom area, while increasing weld penetration, metal melting area, and arc voltage. These results indicate that the compound excitation device can effectively regulate the heat input distribution and arc heat flux density.

Similar content being viewed by others

Data availability

Not applicable.

Code availability

Not applicable.

References

Kalyankar V, Bhoskar A, Deshmukh D, Patil S (2022) On the performance of metallurgical behaviour of Stellite 6 cladding deposited on SS316L substrate with PTAW process. Can Metall Quart 61(2):130–144. https://doi.org/10.1080/00084433.2022.2031681

Bhoskar A, Kalyankar V, Deshmukh D (2022) Metallurgical characterisation of multi-track Stellite 6 coating on SS316L substrate. Can Metall Quart 62(4):665–677. https://doi.org/10.1080/00084433.2022.2149009

Kalyankar V, Bhoskar A (2021) Influence of torch oscillation on the microstructure of Colmonoy 6 overlay deposition on SS304 substrate with PTA welding process. Metall Res Technol 118(4):406. https://doi.org/10.1051/metal/2021045

Dak G, Pandey C (2020) A critical review on dissimilar welds joint between martensitic and austenitic steel for power plant application. J Manuf Process 58:377–406. https://doi.org/10.1016/j.jmapro.2020.08.019

Mittal R, Sidhu BS (2015) Microstructures and mechanical properties of dissimilar T91/347H steel weldments. J Mater Process Technol 220:76–86. https://doi.org/10.1016/j.jmatprotec.2015.01.008

Echezona N, Akinlabi S, Jen T, Fatoba O, Hassan S, Akinlabi E (2021) Tig welding of dissimilar steel: a review. Adv Mater Sci Eng 1–9. https://doi.org/10.1007/978-981-16-3641-7_1

Li H, Liu D, Ma Q, Guo N, Song X, Feng J (2019) Microstructure and mechanical properties of dissimilar welds between 16Mn and 304L in underwater wet welding. Sci Technol Weld Join 24(1):1–7. https://doi.org/10.1080/13621718.2018.1467847

Song Y, Chen G, Wang J, Liu J, Yu X, Hua J, Bai X, Zhang T, Zhang J, Tang W (2014) Short-term high-temperature tensile tests and prediction of long-term strength of welded joints of dissimilar steels T92/HR3C. Met Sci Heat Treat 55:614–621. https://doi.org/10.1007/s11041-014-9678-0

Vora JJ, Badheka VJ (2015) Experimental investigation on mechanism and weld morphology of activated TIG welded bead-on-plate weldments of reduced activation ferritic/martensitic steel using oxide fluxes. J Manuf Process 20:224–233. https://doi.org/10.1016/j.jmapro.2015.07.006

Vidyarthy RS, Dwivedi DK (2018) Microstructural and mechanical properties assessment of the P91 A-TIG weld joints. J Manuf Process 31:523–535. https://doi.org/10.1016/j.jmapro.2017.12.012

Reis RP, Souza D, Scotti A (2011) Models to describe plasma jet, arc trajectory and arc blow formation in arc welding. Weld World 55:24–32. https://doi.org/10.1007/BF03321283

Okano S, Kotani Y, Tsuyama T, Mochizuki M (2017) Distortion control by welding with trailing reverse side flame heating. Weld J 96(1):31s–38s

Hwang I, Kim DY, Jeong G, Kang M, Kim D, Kim YM (2017) Effect of weld bead shape on the fatigue behavior of GMAW lap fillet joint in GA 590 MPa steel sheets. Metals 7(10):399. https://doi.org/10.3390/met7100399

Chen HC, Ng FL, Du ZL (2019) Hybrid laser-TIG welding of dissimilar ferrous steels: 10 mm thick low carbon steel to 304 austenitic stainless steel. J Manuf Process 47:324–336. https://doi.org/10.1016/j.jmapro.2019.10.013

Fei Z, Pan Z, Cuiuri D, Li H, Van Duin S, Yu Z (2019) Microstructural characterization and mechanical properties of K-TIG welded SAF2205/AISI316L dissimilar joint. J Manuf Process 45:340–355. https://doi.org/10.1016/j.jmapro.2019.07.017

Yue J, Chang Y, Guo R, Liu W, Li L (2019) Coupling relationship between torch migration relative to surface weld pool and penetration morphology in asymmetrical fillet welding. Measurement 135:163–169. https://doi.org/10.1016/j.measurement.2018.11.057

Ogundimu EO, Akinlabi ET, Erinosho MF (2019) Comparative study between TIG and MIG welding processes. J Phys Conf Ser 1378(2):022074. https://doi.org/10.1088/1742-6596/1378/2/022074

Wu H, Chang Y, Lu L, Bai J (2017) Review on magnetically controlled arc welding process. Int J Adv Manuf Technol 91:4263–4273. https://doi.org/10.1007/s00170-017-0068-9

Wang L, Chen J, Wu C (2021) Auxiliary energy-assisted arc welding processes and their modelling, sensing and control. Sci Technol Weld Join 26(5):389–411. https://doi.org/10.1080/13621718.2021.1926659

Xiao L, Fan D, Huang J, Tashiro S, Tanaka M (2020) Numerical study on arc-droplet coupled behavior in magnetic field controlled GMAW process. J Phys D Appl Phys 53(11):115202. https://doi.org/10.1088/1361-6463/ab6020

Da Cunha TV, Silva KB, Voigt AL (2022) Experimental investigations on the arc’s physical aspects and their implications on weld bead morphology and microstructure in TIG welding with an external longitudinal magnetic field. Weld World 66(8):1675–1689. https://doi.org/10.1007/s40194-022-01317-1

Zhao M, Chen J, Yu M, Li B, Feng X (2020) Effect of transverse magnetic field on weld formation and microstructure & properties of high-speed hot-wire tungsten inert gas welding joints. Sci Technol Weld Join 25(5):407–414. https://doi.org/10.1080/13621718.2020.1730546

Wang L, Wu C, Chen J, Gao J (2020) Experimental measurement of fluid flow in high-speed GMAW assisted by transverse magnetic field. J Manuf Process 56:1193–1200. https://doi.org/10.1016/j.jmapro.2020.06.006

Espina-Hernandez JH, Caleyo F, Hallen JM, Rueda-Morales GL, Perez-Baruch E, Lopez-Montenegro A (2010) Method to reduce arc blow during DC arc welding of pipelines. 8th International Pipeline Conference-Proceedings of the ASME International Pipeline Conference. Calgary, Alberta, Canada 3:387–392. https://doi.org/10.1115/IPC2010-31393

Jian X, Wu H (2020) Influence of the longitudinal magnetic field on the formation of the bead in narrow gap gas tungsten arc welding. Metals 10(10):1351. https://doi.org/10.3390/met10101351

Li F, Liu Y, Jin P, Chen M, Ke W, Du Y, Liu J, Sun Q (2021) Appreciable-tuned ferrite/austenite phase balance in the fusion zone of GTAW welds via an assisted magnetic field. J Alloy Compd 885:160851. https://doi.org/10.1016/j.jallcom.2021.160851

Nomura K, Ogino Y, Hirata Y (2012) Shape control of TIG arc plasma by cusp-type magnetic field with permanent magnet. Weld Int 26(10):759–764. https://doi.org/10.1080/09507116.2011.592691

Wu H, Chang Y, Guan Z, Babkin A, Lee B (2021) Arc shape and microstructural analysis of TIG welding with an alternating cusp-shaped magnetic field. J Mater Process Technol 289:116912. https://doi.org/10.1016/j.jmatprotec.2020.116912

Antonello MG, Bracarense AQ, Scheuer CJ, Daudr ND (2021) Effect of electromagnetic arc constriction applied in GTAW-based wire arc additive manufacturing on walls’ geometry and microstructure. J Manuf Process 71:156–167. https://doi.org/10.1016/j.jmapro.2021.09.015

Liu S, Liu ZM, Zhao XC, Fan XG (2020) Influence of cusp magnetic field configuration on K-TIG welding arc penetration behavior. J Manuf Process 53:229–237. https://doi.org/10.1016/j.jmapro.2020.02.027

Baskoro AS, Fauzian A, Basalamah H, Kiswanto G, Winarto W (2018) Improving weld penetration by employing of magnetic poles’ configurations to an autogenous tungsten inert gas (TIG) welding. Int J Adv Manuf Technol 99:1603–1613. https://doi.org/10.1007/s00170-018-2552-2

Antonello MG, Bracarense AQ, Silva RHGe, Pigozzo IO, Okuyama MP, (2022) Electric arc shape and weld bead geometry analysis under the electromagnetic constriction and expansion effect. Int J Adv Manuf Technol 118(5–6):1689–1701. https://doi.org/10.1007/s00170-021-08064-5

Antonello MG, Bracarense AQ (2020) Device design for electric arc electromagnetic constriction. Soldagem Insp 25:e2539. https://doi.org/10.1590/0104-9224/si25.39

Luo J, Jia CS, Wang YS, Xue J, Wu YX (2001) Mechanism of the gas tungsten-arc welding in longitudinal magnetic field controlling—I. Property of the arc. Acta Metall Sin 37(2):212–216

Zhao PS, Zhu SY, Zhao GH (1986) Physical features and welding characteristics of a plasma arc re-constricted by a dual-cusp magnetic field. Trans China Weld Inst 7(1):7–14

Funding

This work was supported by the Open Project Program of Opto-Mechatronic Equipment Technology Beijing Area Major Laboratory (Grant No. BIPT-OMET-2022–01) and the Research Project of Tianjin Education Commission(2019KJ011&2019ZD07).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. The first draft of the manuscript was written by Wei Zhou. Wei Zhou: experiment, methodology, writing — original draft preparation. Jianfeng Yue: supervision, validation. Pu Zhong: writing — reviewing, investigation, data curation. Haojie Chen: writing — reviewing, validation. Hao Zhou: writing — reviewing, validation.

All authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhou, W., Yue, J., Zhong, P. et al. Study on the heat input regulation mechanism of compound excitation device and its influence on arc shape and penetration behavior in GTAW. Int J Adv Manuf Technol 129, 3269–3282 (2023). https://doi.org/10.1007/s00170-023-12479-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12479-7