Abstract

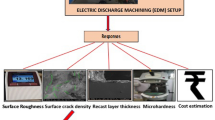

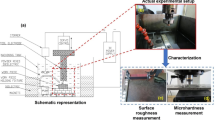

Geometrical inaccuracy is one of the electric discharge machining (EDM) errors and is mainly influenced by the dielectric being used during the operation. The non-conventional machining processes are opted over traditional machining operations due to the greater strength of Ni-based superalloy, specially, Inconel 617 (IN617). But still, there is a need to upgrade the dielectric fluid to minimize the overcut. Therefore, this study uses a combination of surfactant-added dielectrics of transformer oil and cryogenically treated (CT) electrodes (copper and brass). One of the exceptional benefits of applying the cryogenic treatment on the electrodes is that it refines the grain size of the electrode which helped in the regular sparking and reduced the dimensional inaccuracy throughout the EDM operation. A set of 20 experiments under the full factorial design technique was implemented. The experimental results have been explained with process physics, and along with simulation to explore the mechanism of machining with mathematical expressions. The machining capabilities of CT electrodes provided greater dimensional accuracy by an average of 17.1% compared to non-CT electrodes. CT brass provided the minimum dimensional inaccuracy (0.023 mm) in T-20. However, the non-CT copper electrode showed the lowest overcut (0.134 mm) obtained transformer oil without the addition of surfactant. The modeling was also performed to measure the crater sizes produced during the machining of Ni-based superalloy. The simulation results revealed that the mean absolute divergence between the current simulation findings and the ones provided in the literature was approximately equal to 5–7%.

Similar content being viewed by others

Data availability

Not applicable.

References

Dhakar K, Dvivedi A, Dhiman A (2016) Experimental investigation on effects of dielectric mediums in near-dry electric discharge machining. J Mech Sci Technol 305(30):2179–2185. https://doi.org/10.1007/S12206-016-0425-X

Tariq U, Joy R, Wu S-H et al (2023) A state-of-the-art digital factory integrating digital twin for laser additive and subtractive manufacturing processes. Rapid Prototyp J. https://doi.org/10.1108/RPJ-03-2023-0113

Singh AK, Mahajan R, Tiwari A et al (2018) Effect of dielectric on electrical discharge machining: a review. IOP Conf Ser Mater Sci Eng 377:012184. https://doi.org/10.1088/1757-899X/377/1/012184

Razak MRA, Liew PJ, Hussein NIS, Ahsan Q (2016) Effect of surfactant on EDM of low conductivity reaction-bonded silicon carbide. Key Eng Mater 701:107–111. https://doi.org/10.4028/WWW.SCIENTIFIC.NET/KEM.701.107

Ishfaq K, Ahmad N, Maqsood MA et al (2023) A systematic study to achieve cleaner and sustainable manufacturing process by using bio-degradable dielectrics. Sustain Mater Technol 37:e00685. https://doi.org/10.1016/J.SUSMAT.2023.E00685

Ishfaq K, Waseem MU, Sana M (2022) Investigating cryogenically treated electrodes’ performance under modified dielectric(s) for EDM of Inconel(617). Mater Manuf Process 37:1902–1911. https://doi.org/10.1080/10426914.2022.2065016

Li W, Guo YB (2013) A two-parameter method to monitor and characterize tool wear in end milling Inconel 718. ASME 2012 Int Manuf Sci Eng Conf Collocated with 40th North Am Manuf Res Conf Particip with Int Conf, MSEC 2012 799–804https://doi.org/10.1115/MSEC2012-7362

Guo YB, Li W, Jawahir IS (2009) Surface integrity characterization and prediction in machining of hardened and difficult-to-machine alloys: a state-of-art research review and analysis. Mach Sci Technol 13:437–470. https://doi.org/10.1080/10910340903454922

Qudeiri JEA, Zaiout A, Mourad AHI et al (2020) Principles and characteristics of different EDM processes in machining tool and die steels. Appl Sci 10:1–46. https://doi.org/10.3390/app10062082

Shastri RK, Mohanty CP, Dash S et al (2022) Reviewing performance measures of the die-sinking electrical discharge machining process: challenges and future scopes. Nanomaterials 12:384. https://doi.org/10.3390/nano12030384

Masuzawa T (2000) State of the art of micromachining. CIRP Ann 49:473–488. https://doi.org/10.1016/S0007-8506(07)63451-9

Wu Z, Lin B, Fan J et al (2022) Effect of dielectric relaxation of epoxy resin on dielectric loss of medium-frequency transformer. IEEE Trans Dielectr Electr Insul 29:1651–1658. https://doi.org/10.1109/TDEI.2022.3193652

Jiang W, Wang H, Xie W, Qu Z (2023) Lithography alignment techniques based on Moiré Fringe. Photonics 10:351. https://doi.org/10.3390/PHOTONICS10040351

Liao Q, Li S, Xi F et al (2023) High-performance silicon carbon anodes based on value-added recycling strategy of end-of-life photovoltaic modules. Energy 281:128345. https://doi.org/10.1016/J.ENERGY.2023.128345

Kolli M, Kumar A (2015) Effect of dielectric fluid with surfactant and graphite powder on Electrical Discharge Machining of titanium alloy using Taguchi method. Eng Sci Technol an Int J 18:524–535. https://doi.org/10.1016/J.JESTCH.2015.03.009

Tsai YY, Lu CT (2007) Influence of current impulse on machining characteristics in EDM. J Mech Sci Technol 21:1617–1621. https://doi.org/10.1007/BF03177384/METRICS

Zhu X, Liu M, Qi X et al (2021) Templateless, plating-free fabrication of flexible transparent electrodes with embedded silver mesh by electric-field-driven microscale 3D printing and hybrid hot embossing. Adv Mater 33:2007772. https://doi.org/10.1002/ADMA.202007772

Zhang H, Zhu X, Tai Y et al (2023) Recent advances in nanofiber-based. Int J Extrem Manuf 5:032005. https://doi.org/10.1088/2631-7990/acdc66

Zhang Z, Chen J, Wang J et al (2022) Effects of solder thickness on interface behavior and nanoindentation characteristics in Cu/Sn/Cu microbumps. Weld World 66:973–983. https://doi.org/10.1007/S40194-022-01261-0/METRICS

Razak MA, Abdul-Rani AM, Nanimina AM (2015) Improving EDM Efficiency with silicon carbide powder-mixed dielectric fluid. Int J Mater Mech Manuf 3:40–43. https://doi.org/10.7763/ijmmm.2015.v3.163

Jafarian F (2020) Electro discharge machining of Inconel 718 alloy and process optimization. Mater Manuf Process 35:95–103. https://doi.org/10.1080/10426914.2020.1711919

Singh K, Kumar Agarwal A, Yadav R (2017) Effect of dielectric fluids used on EDM performance: a review Gianender Kajal Manav Rachna Educational Institutions Ajit Katiyar Manav Rachna Educational Institutions Effect of Dielectric fluids used on EDM Performance: a review. Int J Emerg Technol Eng Res 5:9–16

Liu Y, Fan B, Xu B, Yang B (2023) Ambient-stable polyethyleneimine functionalized Ti3C2Tx nanohybrid corrosion inhibitor for copper in alkaline electrolyte. Mater Lett 337:133979. https://doi.org/10.1016/J.MATLET.2023.133979

Liu Z, Fan B, Zhao J et al (2023) Benzothiazole derivatives-based supramolecular assemblies as efficient corrosion inhibitors for copper in artificial seawater: formation, interfacial release and protective mechanisms. Corros Sci 212:110957. https://doi.org/10.1016/J.CORSCI.2022.110957

Fang JX, Wang JX, Wang YJ et al (2022) Microstructure evolution and deformation behavior during stretching of a compositionally inhomogeneous TWIP-TRIP cantor-like alloy by laser powder deposition. Mater Sci Eng A 847:143319. https://doi.org/10.1016/J.MSEA.2022.143319

Zhao P, Zhu J, Yang K et al (2023) Outstanding wear resistance of plasma sprayed high-entropy monoboride composite coating by inducing phase structural cooperative mechanism. Appl Surf Sci 616:156516. https://doi.org/10.1016/J.APSUSC.2023.156516

Zhao P, Zhu J, Li M et al (2023) Theoretical and experimental investigations on the phase stability and fabrication of high-entropy monoborides. J Eur Ceram Soc 43:2320–2330. https://doi.org/10.1016/J.JEURCERAMSOC.2023.01.026

Kuang W, Wang H, Li X et al (2018) Application of the thermodynamic extremal principle to diffusion-controlled phase transformations in Fe-C-X alloys: Modeling and applications. Acta Mater 159:16–30. https://doi.org/10.1016/J.ACTAMAT.2018.08.008

Joshi AY, Joshi AY (2019) A systematic review on powder mixed electrical discharge machining. Heliyon 5:e02963. https://doi.org/10.1016/j.heliyon.2019.e02963

Zuo L, Yu S, Zhang R et al (2023) Tunning Pd–Cu-based catalytic oxygen carrier for intensifying low-temperature methanol reforming. J Clean Prod 410:137212. https://doi.org/10.1016/J.JCLEPRO.2023.137212

Xu X, Hao Y, Dong R et al (2023) Effect of undercooling on microstructure evolution of Cu based alloys. J Alloys Compd 935:167998. https://doi.org/10.1016/J.JALLCOM.2022.167998

Zhao Y, Zhang B, Hou H et al (2019) Phase-field simulation for the evolution of solid/liquid interface front in directional solidification process. J Mater Sci Technol 35:1044–1052. https://doi.org/10.1016/J.JMST.2018.12.009

Zhao Y (2023) Understanding and design of metallic alloys guided by phase-field simulations. npj Comput Mater 91(9):1–25. https://doi.org/10.1038/s41524-023-01038-z

Tian X, Zhao Y, Gu T et al (2022) Cooperative effect of strength and ductility processed by thermomechanical treatment for Cu–Al–Ni alloy. Mater Sci Eng A 849:143485. https://doi.org/10.1016/J.MSEA.2022.143485

Xie B, Li H, Ning Y, Fu M (2023) Discontinuous dynamic recrystallization and nucleation mechanisms associated with 2-, 3- and 4-grain junctions of polycrystalline nickel-based superalloys. Mater Des 231:112041. https://doi.org/10.1016/J.MATDES.2023.112041

Ishfaq K, Sana M, Ashraf WM, Dua V (2023) Sustainable EDM of Inconel 600 in Cu-mixed biodegradable dielectrics: modelling and optimizing the process by artificial neural network for supporting net-zero from industry. J Clean Prod 421:138388. https://doi.org/10.1016/J.JCLEPRO.2023.138388

Al-Amin M, Abdul-Rani AM, Rana M et al (2022) Evaluation of modified 316L surface properties through HAp suspended EDM process for biomedical application. Surf Interfaces 28:101600. https://doi.org/10.1016/J.SURFIN.2021.101600

Qazi MJ, Schlegel SJ, Backus EHG et al (2020) Dynamic surface tension of surfactants in the presence of high salt concentrations. Langmuir 36:7956–7964. https://doi.org/10.1021/ACS.LANGMUIR.0C01211/ASSET/IMAGES/LARGE/LA0C01211_0004.JPEG

Zhou S, Zhou G, Liu X, Zhao H (2023) Dynamic freewheeling control for SIDO buck converter with fast transient performance, minimized cross-regulation, and high efficiency. IEEE Trans Ind Electron 70:1467–1477. https://doi.org/10.1109/TIE.2022.3156169

Chen Y, Sun S, Zhang T et al (2020) Effects of post-weld heat treatment on the microstructure and mechanical properties of laser-welded NiTi/304SS joint with Ni filler. Mater Sci Eng A 771:138545. https://doi.org/10.1016/J.MSEA.2019.138545

Lu C, Xu C, Sun W et al (2023) Enhancing catalytic activity of CO2 electrolysis by building efficient and durable heterostructure for solid oxide electrolysis cell cathode. J Power Source 574:233134. https://doi.org/10.1016/J.JPOWSOUR.2023.233134

Zhu ZY, Liu YL, Gou GQ et al (2021) Effect of heat input on interfacial characterization of the butter joint of hot-rolling CP-Ti/Q235 bimetallic sheets by Laser + CMT. Sci Reports 111(11):1–11. https://doi.org/10.1038/s41598-021-89343-9

Fu ZH, Yang BJ, Shan ML et al (2020) Hydrogen embrittlement behavior of SUS301L-MT stainless steel laser-arc hybrid welded joint localized zones. Corros Sci 164:108337. https://doi.org/10.1016/J.CORSCI.2019.108337

Zhu Q, Chen J, Gou G et al (2017) Ameliorated longitudinal critically refracted—attenuation velocity method for welding residual stress measurement. J Mater Process Technol 246:267–275. https://doi.org/10.1016/J.JMATPROTEC.2017.03.022

Ilani MA, Khoshnevisan M (2021) Study of surfactant effects on intermolecular forces (IMF) in powder-mixed electrical discharge machining (EDM) of Ti-6Al-4V. Int J Adv Manuf Technol 116:1763–1782. https://doi.org/10.1007/S00170-021-07569-3/FIGURES/30

Bart JCJ, Gucciardi E, Cavallaro S (2013) Formulating lubricating oils. In: Biolubricants: science and technology. Woodhead Publishing Ltd, Cambridge, pp 351–395

Kumar S, Khedkar NK, Jagtap B, Singh TP (2017) The effects of cryogenic treatment on cutting tools. IOP Conf Ser Mater Sci Eng 225:012104. https://doi.org/10.1088/1757-899x/225/1/012104

Özdemir Z (2021) Shallow Cryogenic Treatment (SCT) Effects on the mechanical properties of high Cr cast iron: low-carbon cast steel bimetallic casting. Int J Met 15:952–961. https://doi.org/10.1007/S40962-020-00532-0/METRICS

Senthilkumar D, Rajendran I (2011) Influence of shallow and deep cryogenic treatment on tribological behavior of En 19 steel. J Iron Steel Res Int 18:53–59. https://doi.org/10.1016/S1006-706X(12)60034-X

Tiwary AP, Pradhan BB, Bhattacharyya B (2018) Investigation on the effect of dielectrics during micro-electro-discharge machining of Ti-6Al-4V. Int J Adv Manuf Technol 95:861–874. https://doi.org/10.1007/S00170-017-1231-Z/METRICS

Ahmed N, Ishfaq K, Rafaqat M et al (2019) EDM of Ti-6Al-4V: electrode and polarity selection for minimum tool wear rate and overcut. Mater Manuf Process 34:769–778. https://doi.org/10.1080/10426914.2019.1594278

Singh S, Maheshwari S, Pandey PC (2004) Some investigations into the electric discharge machining of hardened tool steel using different electrode materials. J Mater Process Technol 149:272–277. https://doi.org/10.1016/J.JMATPROTEC.2003.11.046

Sivakumar KM, Gandhinathan R (2013) Establishing optimum process parameters for machining titanium alloys ( Ti6Al4V ) in spark electric discharge machining. Int J Eng Adv Technol 2:201–204

Singh B, Kumar P, Goutam A, Anand K (2014) Analysis of machining parameters for dimensional accuracy in EDM using Taguchi’s Doe. Int J Eng Res Technol 3:113–117

Kumar P, Dewangan S, Pandey C (2020) Analysis of surface integrity and dimensional accuracy in EDM of P91 steels. Mater Today Proc 33:5378–5383. https://doi.org/10.1016/J.MATPR.2020.03.119

Singh Grewal G, Parkash Dhiman D (2019) Effect of deep cryogenic treatment on copper electrode for non-traditional electric discharge machining (EDM). Mech Sci 10:413–427. https://doi.org/10.5194/MS-10-413-2019

Khan MAR, Rahman MM, Kadirgama K (2014) An experimental investigation on surface finish in die-sinking EDM of Ti-5Al-2.5Sn. Int J Adv Manuf Technol 77:1727–1740. https://doi.org/10.1007/S00170-014-6507-Y

Khan AA (2007) Electrode wear and material removal rate during EDM of aluminum and mild steel using copper and brass electrodes. Int J Adv Manuf Technol 395(39):482–487. https://doi.org/10.1007/S00170-007-1241-3

Hosni NAJ, Lajis MA (2020) Experimental investigation and economic analysis of surfactant (Span-20) in powder mixed electrical discharge machining (PMEDM) of AISI D2 hardened steel. Mach Sci Technol 24:398–424. https://doi.org/10.1080/10910344.2019.1698609

Kassem MGA, Ahmed AMM, Abdel-Rahman HH, Moustafa AHE (2019) Use of Span 80 and Tween 80 for blending gasoline and alcohol in spark ignition engines. Energy Rep 5:221–230. https://doi.org/10.1016/J.EGYR.2019.01.009

Reddy VV, Kumar A, Valli PM, Reddy CS (2014) Influence of surfactant and graphite powder concentration on electrical discharge machining of PH17-4 stainless steel. J Braz Soc Mech Sci Eng 372(37):641–655. https://doi.org/10.1007/S40430-014-0193-4

Shankar P, Jain VK, Sundararajan T (2007) Analysis of spark profiles during EDM process. Mach Sci Technol 1:195–217. https://doi.org/10.1080/10940349708945647

Shao B, Rajurkar KP (2015) Modelling of the crater formation in micro-EDM. Procedia CIRP 33:376–381. https://doi.org/10.1016/J.PROCIR.2015.06.085

Feng X, Wong YS, Hong GS (2016) Characterization and geometric modeling of single and overlapping craters in micro-EDM. Mach Sci Technol 20:79–98. https://doi.org/10.1080/10910344.2015.1085317

Ishfaq K, Mahmood MA, Khan AR, Rehman M (2022) Mathematical modelling with experimental correlation for multiple craters dimension, material removal rate and surface roughness in electrical discharge machining. Int J Adv Manuf Technol 120:227–236. https://doi.org/10.1007/S00170-021-08582-2/FIGURES/10

Mahmood MA, Popescu AC, Hapenciuc CL et al (2020) Estimation of clad geometry and corresponding residual stress distribution in laser melting deposition: analytical modeling and experimental correlations. Int J Adv Manuf Technol 111:77–91. https://doi.org/10.1007/S00170-020-06047-6/FIGURES/9

Ikai T, Hashigushi K (1995) Heat input for crater formation in EDM. In: Proceedings of the International Symposium for Electro-Machining-ISEM XI, EPFL, pp 163–170

Mirkoohi E, Ning J, Bocchini P et al (2018) Thermal modeling of temperature distribution in metal additive manufacturing considering effects of build layers, latent heat, and temperature-sensitivity of material properties. J Manuf Mater Process 2:63. https://doi.org/10.3390/jmmp2030063

Ning J, Sievers DE, Garmestani H, Liang SY (2020) Analytical modeling of part porosity in metal additive manufacturing. Int J Mech Sci 172:105428. https://doi.org/10.1016/J.IJMECSCI.2020.105428

Mohanty CP, Mahapatra SS, Singh MR (2017) An intelligent approach to optimize the EDM process parameters using utility concept and QPSO algorithm. Eng Sci Technol Int J 20:552–562. https://doi.org/10.1016/J.JESTCH.2016.07.003

Ishfaq K, Zahoor S, Khan SA et al (2021) Minimizing the corner errors (top and bottom) at optimized cutting rate and surface finish during WEDM of Al6061. Eng Sci Technol Int J 24:1027–1041. https://doi.org/10.1016/J.JESTCH.2021.01.008

Ishfaq K, Sana M, Waseem MU et al (2023) Enhancing EDM machining precision through deep cryogenically treated electrodes and ANN modelling approach. Micromachines 14:1536. https://doi.org/10.3390/MI14081536

Acknowledgements

The authors appreciate the support from Researchers Supporting Project (RSPD2023R702), King Saud University, Riyadh, Saudi Arabia.

Author information

Authors and Affiliations

Contributions

K.I.: conceptualization, data analysis, resources, methodology, writing and reviewing; M.S.: conceptualization, data analysis, investigation, writing and reviewing; M.A.M.: modeling and validation, software writing, visualization, writing and reviewing; S.A.: visualization, validation, writing and reviewing; M.U.W.: conceptualization, data analysis, investigation, writing and reviewing. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ishfaq, K., Sana, M., Waseem, M. et al. Mathematical modeling and experimental evaluation of superalloy EDM using cryogenically treated electrodes and transformer oil-based dielectrics: a correlation study. Int J Adv Manuf Technol 129, 1649–1663 (2023). https://doi.org/10.1007/s00170-023-12398-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12398-7