Abstract

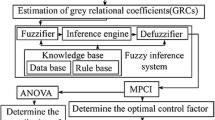

In this research, a double fuzzy system is presented. This system is defined to approximate the geometry of the weld bead in a 5052-H32 aluminum alloy together with its quality regarding the parameters of voltage, current, and advance speed of a semiautomated GMAW (gas metal arc welding) process. These three welding process parameters affect crown concavity, root concavity, and penetration. That is, the welding parameters affect the weld bead geometries. This is relevant since the quality of the beads will be affected by the inappropriate selection of the welding parameter values. The main problem in any welding generated by the semi-automated GMAW process is the uncertainty in the quality of the weld beads; this occurs because the parameters have an inherent variation that affects the generation of the weld beads. Several researchers agree that welding processes have non-linear behavior, inherent variability, and non-normal conditions to satisfy the use of statistical techniques. In addition, these processes are complex due to thermal, electrical, and mechanical phenomena during welding. For this reason, this research proposes to use soft computing techniques, specifically fuzzy logic. This technique is defined for the analysis and inference of the geometry of the weld bead in the 5052-H32 aluminum alloy semi-automated GMAW process.

Similar content being viewed by others

References

Society, AW (1996) Manual de Soldadura. O’Brien, R.L

Mathers, G (2002) The welding of aluminum and its alloys. Woodhead Publishing Limited

Guliáev AP (1978) Metalografía Tomo I. Mir

Committee on structural welding, A (2003) AWS D1.2/D1.2M Código de Soldadura Estructural Para Aluminio. American welding society

Rampos D, López I, Perez P (2013) Effect of process parameters on robotic GMAW bead area estimation. Procedia Technology 17:398–405. https://doi.org/10.1016/j.protcy.2013.04.050

Kolahan, F, Heidari, M (2010) A new approach for predicting and optimizing weld bead geometry in GMAW. International Journal of Mechanical Systems Science and Engineering, pp 138–142

Dorta M, Vidal J, Mateo A, Fargas G, Camejo F (2011) Empirical expression for the prediction of penetration in butt joints for duplex stainless steel saf 2205. DYNA 78(169):206–215

Miguel V, Martínez E, Segura F, Manjabacas M, Abellán E (2012) Optimización del proceso de soldadura GMAW de uniones a topede la aleación aa 6063–t5 basada en la metodología de superficiede respuesta y en la geometría del cordón de soldadura. Rev Metal 48:333–350. https://doi.org/10.3989/revmetalm.1169

Terner M, Bayarsaikhan T, Hong H, Lee J (2017) Influence of gas metal arc welding parameters on the bead properties in automatic cladding. Journal of Welding and Joining 35:16–25. https://doi.org/10.5781/JWJ.2017.35.1.16

Sikora R, Chady T, Baniukiewicz P, Piekarczyk B (2009) Automatic classification of welding FLAWS using artificial intelligence algorithms. AIP Conference Proceedings 1096:1182–1189. https://doi.org/10.1063/1.3114089

Dey V, Kumar D, Datta G, Jha M, Saha T, Bapat A (2010) Optimization and prediction of weldment profile in bead-on-plate welding of Al-1100 plates using electron beam. The International Journal of Advanced Manufacturing Technology 48:513–528. https://doi.org/10.1007/s00170-009-2307-1

Rajkumar B, Murugan N (2012) Prediction of weld bead geometry using artificial neural networks on 2205 duplex stainless steel. Eur J Sci Res 78:85–92

Aghakhani M, Mahdipour M, Karami A (2011) Prediction of weld bead dilution in GMAW process using fuzzy logic. Applied Mechanics and Materials 48:3171–3175. https://doi.org/10.4028/www.scientific.net/AMM.110-116.3171

Pedapati S, Shasidaran Kamal, S, Rani, A, (2017) Optimum welding parameter for GMA welding using soft computing techniques. AIP Conference Proceedings 1901. https://doi.org/10.1063/1.5010509

Singh V, Chandrasekaran M, Samanta S, Thirugnanasambandam M (2019) Artificial neural network modelling of weld bead characteristics during GMAW of nitrogen strengthened austenitic stainless steel. AIP Conference Proceedings 2128. https://doi.org/10.1063/1.5117936

Choudhury B, Chandrasekaran M (2020) Electron beam welding of aerospace alloy (inconel 825): a comparative study of RSM and ANN modeling to predict weld bead area. Optik 219. https://doi.org/10.1016/j.ijleo.2020.165206

Vijila S, Ananthalakshmi S, Kalaiselvi M, Vijayan P, Esther V (2021) Development of fuzzy rule based system for prediction of weld bead geometry. AIP Conference Proceedings 2336. https://doi.org/10.1063/5.0046018

Chiñas P, Lopez I, Vazquez J, Navarro J, Hernandez A (2021) Out-of-control multivariate patterns recognition using \({D}^2\) and SVM: a study case for GMAW. Mathematics 9. https://doi.org/10.3390/math9050467

Montgomery, D (2004) Diseño Y Análisis de Experimentos. Limusa Wiley

Walpole, R, Myers, R, Myers, S, Ye, K (2012) Probabilidad Y Estadística Para Ingeniería Y Ciencias. PEARSON

Wackerly, D, Mendenhall, W, Scheaffer, R (2010) Estadística Matemática Con Aplicaciones. CENGAGE Learning

Montgomery, D (2017) Design and analysis of experiments. Wiley, Inc

Ghetiya N, Patel K (2014) Prediction of tensile strength in friction stir welded aluminium alloy using artificial neural network. Procedia Technology 14:274–281. https://doi.org/10.1016/j.protcy.2014.08.036

Penttila S, Kah P, Ratava J, Eskelinen H (2019) Artificial neural network controlled GMAW system: penetration and quality assurance in a multi-pass butt weld application. The International Journal of Advanced Manufacturing Technology 105:3369–3385. https://doi.org/10.1007/s00170-019-04424-4

Leyva J, Chiñas P, Hernandez A, Hernandez G (2020) Electrochemical discharge machining modeling through different soft computing approaches. The International Journal of Advanced Manufacturing Technology 106:3587–3596. https://doi.org/10.1007/s00170-019-04766-z

Manikya K, Srinivasa R (2008) Prediction of bead geometry in pulsed GMA welding using back propagation neural network. J Mater Process Technol 200:300–305. https://doi.org/10.1016/j.jmatprotec.2007.09.034

Ponce, P (2010) Inteligencia artificial con aplicaciones a la ingeniería. Alfaomega

Zilouchian A, Jamshidi M (2001) Intelligent control systems using soft computing methodologies. CRC Press

Shaw I (1998) Fuzzy control of industrial systems theory and applications. Springer

Pascoal, A, Izeda, A, Cecilio, V, Mineiro, N (2018) Robotic welding tests MIG standard and cmt+p in aluminum alloy 6082-t6 for optimization of penetration, cord width and reinforcement. Proceedings 2. https://doi.org/10.3390/ICEM18-05295

Martínez O, López M, Martín F (2006) Redes neuronales artificiales para la predicción de la calidad en soldadura por resistencia por puntos. Rev Metal 42:345–353

Kumar P, Kamboj A (2017) SMAW process parameters optimization using taguchi & fuzzy logic. International Research Journal of Engineering and Technology (IRJET) 04:411–413

Sreeharan B, Kannan T (2017) Process optimization of GMAW over AA6351 aluminium alloy using ANN. International Journal of Civil Engineering and Technology 08:208–218

Funding

This research was partially funded through CONAHCyT research grant CVU 717799 and Tecnológico Nacional de México, Instituto Tecnológico de Saltillo.

Author information

Authors and Affiliations

Contributions

Enrique Alejandro Cavazos Hernández and Pamela Chiñas Sánchez contributed to the conceptualization, design, implementation and matlab programming as well as the design of the double fuzzy system. José Luis Navarro González and Ismael López Juárez conceptualized the use of the normality test and regression analysis as a valid measure to distinguish normality. The first draft of the manuscript was written by Enrique Alejandro Cavazos Hernández and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Ethics approval

The manuscript should not be submitted to more than one journal for simultaneous consideration.

Consent to participate

The authors consent to participate.

Consent for publication

The authors consent for publication.

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Pamela Chiñas Sánchez, José Luis Navarro González, and Ismael López Juárez contributed equally to this work.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Cavazos Hernández, E.A., Chiñas Sánchez, P., Navarro González, J.L. et al. Geometries and quality assesment of weld beads in 5052-H32 aluminum alloys joined by semiautomated GMAW through a double fuzzy system. Int J Adv Manuf Technol 129, 2011–2030 (2023). https://doi.org/10.1007/s00170-023-12337-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12337-6