Abstract

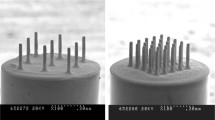

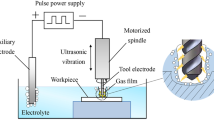

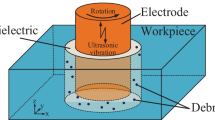

Electrochemical discharge machining (ECDM), as a new type of non-traditional machining method, is widely used in the machining of insulating hard and brittle materials such as glass and ceramics. However, there are some problems such as difficulty in circulating electrolyte, resulting in poor quality machining of deep and small holes. In this paper, electrochemical discharge machining with ultrasonic vibration and tube electrode is used to improve the flow field in the machining gap and enhance the machining quality by using the injected electrolyte inside the tube electrode and ultrasonic vibration. First, the temperature distribution state of electrochemical discharge is simulated, and the influence of the coupling effect of the electrolyte injection and ultrasonic vibration on the machining gap is analyzed. And then, the influence weights of each factor were analyzed by orthogonal experiments and further analyzed to obtain the optimized combination of machining parameters, which reduced the entrance size of small holes by 19.3%, increased the machining depth by 18.5% and increased the depth-to-diameter ratio by 46.2% compared with the traditional ECDM. The effect of ultrasonic vibration was studied on the basis of the optimized machining parameters. The results show that the optimized effect of ultrasonic vibration with an amplitude of 7μm is most obvious under the conditions of low pressure and low injection rate. Finally, with the optimized machining parameters, a 5×5 array of small holes and three deep and small holes were machined, demonstrating that electrochemical discharge machining with ultrasonic vibrating tube electrode can be an efficient and high-quality method for machining small holes.

Similar content being viewed by others

Data Availability

All data generated or analyzed during this study are included within the article.

References

Wang XL, Gao XD, Zhang ZH, Cheng LS, Ma HP, Yang WM (2021) Advances in modifications and high-temperature applications of silicon carbide ceramic matrix composites in aerospace: a focused review. J Eur Ceram Soc 41(9):4671–4688

Kang XM, Tang WD, Zhao WS, Qian J, Lauwers B (2021) Experimental and numerical investigations of material removal process in electrochemical discharge machining of glass in discharge regime. Precis Eng 72:706–716

Sharma P, Mishra DK, Dixit P (2020) Experimental investigations into alumina ceramic micromachining by electrochemical discharge machining process. Procedia Manuf 48:244–250

Singh M, Singh S, Kumar S (2020) Experimental investigation for generation of micro-holes on silicon wafer using electrochemical discharge machining process. Silicon 12(7):1683–1689

Kolhekar KR, Sundaram M (2018) Study of gas film characterization and its effect in electrochemical discharge machining. Precis Eng 53:203–211

Sabahi N, Razfar MR (2018) Investigating the effect of mixed alkaline electrolyte (NaOH + KOH) on the improvement of machining efficiency in 2D electrochemical discharge machining (ECDM). Int J Adv Manuf Technol 95(1-4):643–657

Elhami S, Razfar MR (2020) Application of nano electrolyte in the electrochemical discharge machining process. Precis Eng 64:34–44

Bian JX, Ma BJ, Liu XF, Qi LJ (2020) Experimental study of tool wear in electrochemical discharge machining. Appl Sci 10(15):5039

Sharma P, Dixit P (2022) Investigation of tool wear in alumina micromachining by multi-tip ECDM. Mater Manuf Process 37(3):342–348

Mehrabi F, Farahnakian M, Elhami S, Razfar MR (2018) Application of electrolyte injection to the electro-chemical discharge machining (ECDM) on the optical glass. J Mater Process Technol 255:665–672

Arya RK, Dvivedi A (2019) Investigations on quantification and replenishment of vaporized electrolyte during deep micro-holes drilling using pressurized flow-ECDM process. J Mater Process Technol 266:217–229

Arya RK, Dvivedi A (2019) Enhancement in machining efficiency and accuracy of ECDM process using hollow tool electrode. Springer Singapore, Singapore, pp 313–323

Elhami S, Razfar MR (2018) Effect of ultrasonic vibration on the single discharge of electrochemical discharge machining. Mater Manuf Process 33(4):444–451

Elhami S, Razfar MR (2017) Study of the current signal and material removal during ultrasonic-assisted electrochemical discharge machining. Int J Adv Manuf Technol 92(5-8):1591–1599

Elhami S, Razfar MR (2017) Analytical and experimental study on the integration of ultrasonically vibrated tool into the micro electro-chemical discharge drilling. Precis Eng 47:424–433

Singh T, Dvivedi A, Shanu A, Dixit P (2021) Experimental investigations of energy channelization behavior in ultrasonic assisted electrochemical discharge machining. J Mater Process Technol 293:117084

Rathore RS, Dvivedi A (2020) Sonication of tool electrode for utilizing high discharge energy during ECDM. Mater Manuf Process 35(4):415–429

Rathore RS, Dvivedi A (2020) Experimental investigations and its dimensional analysis–based modeling of the UAECDM process. Int J Adv Manuf Technol 111(11-12):3241–3257

Code availability

Not applicable.

Funding

The authors acknowledge financial support from the National Key R&D Program of China (No. 2018YFB2001400), the National Natural Science Foundation of China (No. 52005298), and the Natural Science Foundation of Shandong Province (No. ZR2021ME048). This work is supported by Physical-Chemical Materials Analytical & Testing Center of Shandong University at Weihai.

Author information

Authors and Affiliations

Contributions

Chenghu Jia performed the experiment, the data analyses, and wrote the manuscript; Yong Liu contributed to the conception of the study and edited the manuscript; others helped perform the analysis with constructive discussions.

Corresponding author

Ethics declarations

Ethics approval

This paper is in compliance with ethical standards.

Consent to participate

All authors agreed with the consent to participate.

Consent for publication

All authors have read and agreed to the publication of the paper.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jia, C., Liu, Y., Wang, T. et al. Study on electrochemical discharge machining of small holes array on glass with ultrasonic vibrating tube electrode. Int J Adv Manuf Technol 129, 547–562 (2023). https://doi.org/10.1007/s00170-023-12304-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12304-1