Abstract

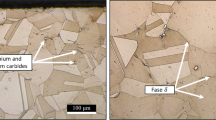

Out of all the mechanical energy generated during material cutting, the majority is converted into heat, raising the temperature at the chip-tool interface, particularly in difficult-to-machine materials like Inconel 718, thereby diminishing tool lifespan. Consequently, various lubri-cooling methods mitigate issues related to high temperatures, such as reduced tool life and geometric distortions. The most employed method is cutting fluids application (CFA), but this approach poses several problems, including high cost and environmental and operator hazards. As a result, several techniques have been developed to lower machining temperatures, such as minimum quantity lubrication (MQL), cryogenics, and indirect tool cooling. In this study, an innovative method of tool cooling via internally cooled tool (ICT) was devised and tested. In this approach, the cooling fluid circulates in a closed loop without direct contact with the workpiece or even any fluid dispersion to the atmosphere, increasing environmental appeal and reducing manufacturing coasts. The developed method was compared with temperature measurements taken through thermography and a tool-workpiece thermocouple during the turning of Inconel 718. Two factorial designs studied temperature in Inconel 718 turning via thermocamera and tool-workpiece thermocouple. Additionally, the tool coating (TiNAl or AlCrN + TiNAl), cutting speed, feed, and depth of cut were varied. Using the tool-workpiece thermocouple method, ICT and CFA did not observe any statistically significant temperature difference. However, between ICT and DM, ICT exhibited a lower temperature at the tool-workpiece interface. With thermal imaging, ICT displayed a lower chip temperature than DM. In sum, internally cooled tools emerge as an innovative and environmentally sustainable solution for machining Inconel 718. They offer outstanding heat removal capabilities and substantial advantages over cutting fluids while significantly surpassing the performance of dry machining, thereby addressing crucial concerns in sustainable machining practices.

Similar content being viewed by others

Data availability

The datasets obtained during the current work are available from the corresponding author upon request.

Code availability

Not applicable.

References

Mahesh K, Philip JT, Joshi SN, Kuriachen B (2021) Machinability of Inconel 718: A critical review on the impact of cutting temperatures. Mater Manuf Process 36:753–791. https://doi.org/10.1080/10426914.2020.1843671

Schmidt AO, Roubik JR (1949) Distribution of heat generated in drilling. Trans Am Soc Mech Eng 71:245–248

Shaw MC (1984) Metal cutting principles. Clarendon

Kronenberg M (1966) Theory and practice for operation and development of machining processes. Machining Science and Application

Klocke F, Kuchle A (2009) Manufacturing processes. Springer, Berlin. https://link.springer.com/content/pdf/10.1007/978-3-642-36772-4.pdf

Grzesik W (2008) Advanced machining processes of metallic materials: theory, modelling and applications. Elsevier

Jamil M, Zhao W, He N et al (2021) Sustainable milling of Ti–6Al–4V: A trade-off between energy efficiency, carbon emissions and machining characteristics under MQL and cryogenic environment. J Clean Prod 281:125374. https://doi.org/10.1016/j.jclepro.2020.125374

da Veiga FL, Faria MIST, Coelho GC (2017) Superliga Inconel-718: Caracterização microestrutural e validação da base de dados termodinâmicos. Cad UniFOA 7:77–85. https://doi.org/10.47385/cadunifoa.v7.n1%20Esp.2185

Marques A (2015) Torneamento de inconel 718 com aplicação de lubrificantes sólidos. Universidade Federal de Uberlândia. https://doi.org/10.14393/ufu.te.2015.151

Roy S, Kumar R, Panda A, Das RK (2018) A brief review on machining of Inconel 718. Mater Today Proc 5:18664–18673. https://doi.org/10.1016/j.matpr.2018.06.212

Yin Q, Liu Z, Wang B et al (2020) Recent progress of machinability and surface integrity for mechanical machining Inconel 718: a review. Int J Adv Manuf Technol 109:215–245. https://doi.org/10.1007/s00170-020-05665-4

Mustafa G, Anwar MT, Ahmed A, et al (2022) Influence of machining parameters on machinability of Inconel 718—a review. Adv Eng Mater 24:. https://doi.org/10.1002/adem.202200202

Rubaiee S, Danish M, Gupta MK et al (2022) Key initiatives to improve the machining characteristics of Inconel-718 alloy: experimental analysis and optimization. J Mater Res Technol 21:2704–2720. https://doi.org/10.1016/j.jmrt.2022.10.060

Byers JP (ed) (2006) Metalworking fluids, 2nd edn. CRC Press. https://doi.org/10.1201/9781420017731

Almeida Carvalho DO, da Silva LRR, de Souza FCR, França PHP, Machado AD, Costa ES, Fernandes GHN, da Silva RB (2022) Flooding application of vegetable-and mineral-based cutting fluids in turning of AISI 1050 steel. Lubricants 10:309. https://doi.org/10.3390/lubricants10110309

Fernandes GHN, Barbosa LMQ (2022) Machining cooling techniques. Recife: Even3 Publicações. https://doi.org/10.29327/559427. https://publicacoes.even3.com.br/book/machining-cooling-techniques-594275

Iturbe A, Hormaetxe E, Garay A, Arrazola PJ (2016) Surface integrity analysis when machining inconel 718 with conventional and cryogenic cooling. Procedia Cirp 45:67–70. https://doi.org/10.1016/j.procir.2016.02.095

Salem A, Hopkins C, Imad M et al (2020) Environmental analysis of sustainable and traditional cooling and lubrication strategies during machining processes. Sustainability 12:8462. https://doi.org/10.3390/su12208462

Ozcelik B, Kuram E, Cetin MH, Demirbas E (2011) Experimental investigations of vegetable based cutting fluids with extreme pressure during turning of AISI 304L. Tribol Int 44:1864–1871. https://doi.org/10.1016/j.triboint.2011.07.012

Ishfaq K, Anjum I, Pruncu CI et al (2021) Progressing towards sustainable machining of steels: a detailed review. Mater. 14:18–5162. https://doi.org/10.3390/ma14185162

Wu X, Li C, Zhou Z et al (2021) Circulating purification of cutting fluid: an overview. Int J Adv Manuf Technol 117:2565–2600. https://doi.org/10.1007/s00170-021-07854-1

Benedicto E, Carou D, Rubio EM (2017) Technical, economic and environmental review of the lubrication/cooling systems used in machining processes. Procedia Eng 184:99–116. https://doi.org/10.1016/j.proeng.2017.04.075

Sankaranarayanan R, Krolczyk GM (2021) A comprehensive review on research developments of vegetable-oil based cutting fluids for sustainable machining challenges. J Manuf Process 67:286–313. https://doi.org/10.1016/j.jmapro.2021.05.002

Demirbas E, Kobya M (2017) Operating cost and treatment of metalworking fluid wastewater by chemical coagulation and electrocoagulation processes. Process Saf Environ Prot 105:79–90. https://doi.org/10.1016/j.psep.2016.10.013

Wang X, Li C, Zhang Y et al (2022) Tribology of enhanced turning using biolubricants: A comparative assessment. Tribol Int 174:107766. https://doi.org/10.1016/j.triboint.2022.107766

Wang X, Li C, Zhang Y et al (2020) Vegetable oil-based nanofluid minimum quantity lubrication turning: Academic review and perspectives. J Manuf Process 59:76–97. https://doi.org/10.1016/j.jmapro.2020.09.044

Şirin E (2023) Evaluation of tribological performance of MQL technique combined with LN2, CO2, N2 ecological cooling/lubrication techniques when turning of Hastelloy C22 superalloy. Tribol Int 188:108786. https://doi.org/10.1016/j.triboint.2023.108786

de Carvalho PP, Fernandes GHN, Barbosa LMQ et al (2023) Different cooling strategies applied during the process of aluminum alloy boring. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-023-11840-0

Guo S, Li C, Zhang Y et al (2017) Experimental evaluation of the lubrication performance of mixtures of castor oil with other vegetable oils in MQL grinding of nickel-based alloy. J Clean Prod 140:1060–1076. https://doi.org/10.1016/j.jclepro.2016.10.073

Fernandes Gustavo et al (2021) Wear mechanisms of diamond-like carbon coated tools in tapping of AA6351 T6 aluminium alloy. Procedia Manufacturing 53:293–298

Zhang J, Li C, Zhang Y et al (2018) Experimental assessment of an environmentally friendly grinding process using nanofluid minimum quantity lubrication with cryogenic air. J Clean Prod 193:236–248. https://doi.org/10.1016/j.jclepro.2018.05.009

Swain S, Patra SK, Roul MK, Sahoo LK (2022) A short review on cooling process using compressed cold air by vortex tube in machining. Mater Today Proc 64:382–389. https://doi.org/10.1016/j.matpr.2022.04.722

Chiou RY, Lu L, Chen JSJ, North MT (2007) Investigation of dry machining with embedded heat pipe cooling by finite element analysis and experiments. Int J Adv Manuf Technol 31:905–914. https://doi.org/10.1007/s00170-005-0266-8

Kantharaj I, Hiran Gabriel DJ, Prakash JB, Mohanasundaram S (2021) Experimental investigation on heat pipe-assisted cooling during milling process of AISI 1040. Lect Notes Mech Eng 601–609. https://doi.org/10.1007/978-981-15-4745-4_53

Meyers PG (1961) Tool cooling apparatus. Attorney: Vernon F. Hauschill. USA n. US3137184. Deposit: 05 Jul 1961, Concession: 16 June 1964, United States Patent Office, 1964. https://patents.google.com/patent/US3137184A/en

Jeffries NP, Zerkle RD (1970) Thermal analysis of an internally-cooled metal-cutting tool. Int J Mach Tool Des Res 10:381–399. https://doi.org/10.1016/0020-7357(70)90019-3

Zerkle RD (1971) Cooling system for cutting tools and the like. US3571877A. https://patents.google.com/patent/US3571877

Barbosa LMQ, França PHP, Fernandes GHN et al (2023) Comparison of the performance of the internally cooled tool in closed circuit against standard PCBN tools in turning AISI D6 hardened. Journal of Manufacturing Process

Nazareno Fernandes GH, Bazon VT, Queiroz Barbosa LM et al (2023) Performance comparison between internally cooled tools and flood cooling during grey cast iron turning. J Manuf Process 85:817–831. https://doi.org/10.1016/j.jmapro.2022.11.040

Wei X (2019) Novel turning tool with an internal cooling system. The University of Manchester, United Kingdom. https://www.proquest.com/openview/da3066549b8283bc5e064eff2df6e564/1?pq-origsite=gscholar&cbl=2026366&diss=y

Rozzi JC, Chen W, Chen EE (2011) U.S. Patent No. 8,061,241. U.S. Patent and Trademark Office, Washington, DC

França PHP, Barbosa LMQ, Fernandes GHN et al (2022) Thermal analysis of a proposed internally cooled machining tool system. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-022-10602-8

Peixoto A (2021) Análise da força de corte e rugosidade no torneamento de ferro fundido cinzento utilizando sistema de resfriamento interno da ferramenta (Analysis of cutting force and roughness in gray cast iron turning using internal tool cooling system). Universidade Federal de Uberlândia. https://doi.org/10.14393/ufu.di.2021.5592

ASM International (1990) ASM Handbook, vol 2. Nonferrous Alloys and Special-Purpose Materials, Properties and Selection

Ceratizit (2022) CNMG. In: webpage. https://cuttingtools.ceratizit.com/ie/en/products/7500363000.html?referrer=https%3A%2F%2Fwww.google.com%2F. Accessed 11 Apr 2022

Meola, C., & Carlomagno, G. M. (2004). Recent advances in the use of infrared thermography. Measurement science and technology, 15(9), R27. https://doi.org/10.1088/0957-0233/15/9/R01

Da Silva LRR, Filho AF, Costa ES et al (2018) Cutting temperatures in end milling of compacted graphite irons. Procedia Manufacturing. Elsevier B.V., pp 474–484. https://doi.org/10.1016/j.promfg.2018.07.056

da Silva MB, Wallbank J (1999) Cutting temperature: prediction and measurement methods—a review. J Mater Process Technol 88:195–202. https://doi.org/10.1016/S0924-0136(98)00395-1

Davoodi B, Hosseinzadeh H (2012) A new method for heat measurement during high speed machining. Measurement 45:2135–2140. https://doi.org/10.1016/j.measurement.2012.05.020

Dubey V, Sharma AK, Singh RK (2021) A technological review on temperature measurement techniques in various machining processes. Advances in Metrology and Measurement of Engineering Surfaces: Select Proceedings of ICFMMP 2019. pp 55–67. https://doi.org/10.1007/978-981-15-5151-2_6

Zhao J, Liu Z, Wang B et al (2018) Cutting temperature measurement using an improved two-color infrared thermometer in turning Inconel 718 with whisker-reinforced ceramic tools. Ceram Int 44:19002–19007. https://doi.org/10.1016/j.ceramint.2018.07.142

Kaminise AK, Guimarães G, da Silva MB (2014) Development of a tool–work thermocouple calibration system with physical compensation to study the influence of tool-holder material on cutting temperature in machining. Int J Adv Manuf Technol 73:735–747. https://doi.org/10.1007/s00170-014-5898-0

Agapiou JS, Stephenson DA (1994) Analytical and experimental studies of drill temperatures. Anal Eng Indust 116(1):54–60. https://doi.org/10.1115/1.2901809

Astakhov VP, Outeiro J (2019) Importance of temperature in metal cutting and its proper measurement/modelin. Measurement in Machining and Tribology 1–47. https://doi.org/10.1007/978-3-030-03822-9_1

França PHP (2021) Estudo da temperatura em ferramentas de usinagem com canais de refrigeração internos no torneamento do ferro fundido cinzento. Dissertação (Mestrado em Engenharia Mecânica). Universidade Federal de Uberlândia, Uberlândia. https://doi.org/10.14393/ufu.di.2021.283

Lima Júnior EDE (2020) Medição da temperatura de corte no torneamento do aço-ferramenta AISI D6 temperado e revenido auxiliado por LN2. 2020. 135f. Dissertação (Mestrado em Engenharia Mecânica. Centro de Tecnologia, Universidade Federal do Rio Grande do Norte, Natal. https://repositorio.ufrn.br/handle/123456789/28897

Korkut I, Boy M, Karacan I, Seker U (2007) Investigation of chip-back temperature during machining depending on cutting parameters. Mater Des 28:2329–2335. https://doi.org/10.1016/j.matdes.2006.07.009

O’Sullivan D, Cotterell M (2002) Workpiece temperature measurement in machining. Proc Inst Mech Eng Part B J Eng Manuf 216:135–139. https://doi.org/10.1243/0954405021519645

Trent EM, Wright PK (2000) Metal cutting, 4th edn. Butterworth-Heinemann

Kus A, Isik Y, Cakir MC et al (2015) Thermocouple and infrared sensor-based measurement of temperature distribution in metal cutting. Sensors 15:1274–1291. https://doi.org/10.3390/s150101274

Kusiak A, Battaglia J-L, Rech J (2005) Tool coatings influence on the heat transfer in the tool during machining. Surf Coatings Technol 195:29–40. https://doi.org/10.1016/j.surfcoat.2005.01.007

Zhao J, Liu Z, Wang B et al (2021) Tool coating effects on cutting temperature during metal cutting processes: comprehensive review and future research directions. Mech Syst Signal Process 150:107302. https://doi.org/10.1016/j.ymssp.2020.107302

Machado ÁR, Coelho RT, Abrão AM, da Silva MB (2015) Teoria da usinagem dos materiais. Editora Blucher

Itakura, K., Kuroda, M., Omokawa, H., Itani, H., Yamamoto, K., & Ariura, Y. (1999). Wear mechanism of coated cemented carbide tool in cutting of Inconel 718 super-heat-resisting alloy. International Journal of the Japan Society for Precision Engineering, 33(4), 326-332.

Klocke E (1997) Dry cutting. Cirp Ann 46:519–526. https://doi.org/10.1016/S0007-8506(07)60877-4

Fernandes GHN, Barbosa LMQ (2022) Heat in machining. In: Fernandes GHN, Barbosa LMQ (eds) Machining cooling techniques an introduction, 1st edn. Even3, Recife, pp 10–24. https://doi.org/10.29327/559427.1-1

Kelly JF, Cotterell MG (2002) Minimal lubrication machining of aluminium alloys. J Mater Process Technol 120:327–334. https://doi.org/10.1016/S0924-0136(01)01126-8

Amigo FJ, Urbikain G, Pereira O et al (2020) Combination of high feed turning with cryogenic cooling on Haynes 263 and Inconel 718 superalloys. J Manuf Process 58:208–222. https://doi.org/10.1016/j.jmapro.2020.08.029

Neto, R. R. I., Fragelli, R. L., Fiocchi, A. A., Scalon, V. L., & de Angelo Sanchez, L. E. (2015). Toolholder Internally Cooled by a Phase Change Fluid in Turning of SAE. Applied Mechanics and Materials, 798, 486–490.

BALZERS, Oerlikon (org.) (2023) BALINIT ALNOVA: reliable milling of the most demanding materials. Reliable milling of the most demanding materials. Oerlikon Balzers. Available from: https://www.oerlikon.com/balzers/sg/en/portfolio/balzers-surfae-solutions/pvd-and-pacvd-based-coating-solutions/balinit/alcrnbased/balinit-alnova/. Accessed 30 Aug 2023

Haapala KR, Zhao F, Camelio J, Sutherland JW, Skerlos SJ, Dornfeld DA, Rickli JL (2013) A review of engineering research in sustainable manufacturing. Journal of manufacturing science and engineering 135(4):041013. https://doi.org/10.1115/1.4024040

OECD, P. B. (2009) Sustainable manufacturing and eco-innovation: towards a green economy. Policy Brief-OECD Observer

Hsien WLY (2015) Towards green lubrication in machining. Springer, Singapore, p 7

Palanikumar K, Boppana SB, Natarajan E (2023) Analysis of chip formation and temperature measurement in machining of titanium alloy (Ti-6Al-4V). Exp Tech 47:517–529. https://doi.org/10.1007/s40799-021-00537-2

Fernandes Gustavo et al (2023) Towards green machining: wear analysis of a novel eco-friendly cooling strategy for Inconel 718. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-023-12207-1

Acknowledgements

The authors would like to thank the following: The Grupo de Manufatura Sustentável (GMS) (Group of Manufacture Sustainable (GMS)) of the Laboratório de Ensino e Pesquisa em Usinagem (LEPU) at the Federal University of Uberlandia–Brazil; NipoTec–Special Tools; Walter Tools and Secco Tools; Villares Metals SA; Fiat Chrysler Automobiles (FCA). This work was supported by the Brazilian research agencies: Coordenação de Aperfeiçoamento de Pessoal de Nível Superior-Brasil (CAPES) (grant number 001, 2019), the Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) (grant number 001,2019), and Fundação de Amparo à Pesquisa do Estado de Minas Gerais (FAPEMIG) (grant number 001,2019).

Funding

This study was funded by Tupy S.A. which provided the work material, Walter Tools donated the tools, Nipo-Tec Ferramentas Industriais designed and machined the channels of the ICT inserts by REDM, and Brazilian research agencies CNPq, FAPEMIG, and Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001 financially supported.

Author information

Authors and Affiliations

Contributions

Gustavo Henrique Nazareno Fernandes: conceptualization, methodology, validation, formal analysis, investigation, writing—original draft, visualization, project administration.

Lucas Melo Queiroz Barbosa: validation, investigation, data curation, writing—review and editing.

Pedro Henrique Pires França: validation, investigation, data curation.

Eduardo Ramos Ferreira: validation, investigation, data curation.

Paulo S. Martins: funding acquisition; supervision; writing—review and editing; project administration.

Álisson R. Machado: writing—review and editing; supervision; project administration.

Notice: Some parts of this article were rewritten with the help of artificial intelligence to improve writing fluency.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics approval

This article requires informed consent of the authors; it does not have any disclosure of potential conflicts of interest and does not involve human and/or animal participants.

Consent to participate

The authors declare they consent to participate in this paper.

Consent to publish

The authors declare they consent to publish this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fernandes, G.H.N., Barbosa, L.M.Q., França, P.H.P. et al. Enhancing sustainability in Inconel 718 machining: temperature control with internally cooled tools. Int J Adv Manuf Technol 131, 2771–2789 (2024). https://doi.org/10.1007/s00170-023-12296-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12296-y