Abstract

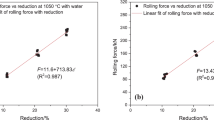

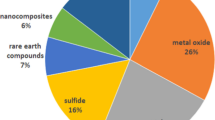

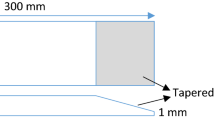

Corrugated rolling is one of the metal forming processes using corrugated rolls to machine hard-to-deform metals, which leads to problems of high friction and severe wear. Lubricants are essential to reduce rolling forces, extend the life of corrugated rolls, and improve efficiency. In this work, a comparison of the surface quality of copper plates after corrugated rolling adopting different lubrication conditions (dry condition, O/W lubricant, TiO2 water-based nanolubricants) was made to explore the tribological behavior and lubricant mechanism of water-based nanolubricant during the corrugated rolling of copper plates. The results show that the 3.0 wt.% water-based nanolubricant exhibits excellent lubrication performance, and the maximum rolling force is reduced by 21.49% compared with the dry condition. Additionally, the effect of reduction on the surface quality of corrugated rolled copper plates was explored. The surface roughness at the peak position of the copper plate increased gradually with increasing reduction, and the surface roughness at the trough position showed little change, which was mainly caused by the synergistic effect of the roughness transfer and the high-strain hardening at the trough position of the copper plate. Overall, an optimal concentration of 3.0 wt.% water-based nanolubricant exhibits the best properties in terms of reducing the rolling forces and improving the surface quality of the rolled copper plates during corrugated rolling processes.

Similar content being viewed by others

Data availability

All data gathered regarding this publication is presented.

Code availability

Not applicable.

References

Zhang SH, Che LZ, Liu XY (2021) Modelling of deformation resistance with big data and its application in the prediction of rolling force of thick plate. Math Probl Eng 2021:2500636

Zhang SH, Deng L, Zhang QY, Li QH, Hou JX (2019) Modeling of rolling force of ultra-heavy plate considering the influence of deformation penetration coefficient. Int J Mech Sci 159:373–381

Zhang SH, Deng L, Che LZ (2022) An integrated model of rolling force for extra-thick plate by combining theoretical model and neural network model. J Manuf Process 75:100–109

Wang T, Wang YL, Bian LP, Huang QX (2019) Microstructural evolution and mechanical behavior of Mg/Al laminated composite sheet by novel corrugated rolling and flat rolling. Mater Sci Eng A 765:138318

He DP, Xu HD, Wang M, Wang T, Ren CR, Wang ZH (2023) Application of dynamic vibration absorber for vertical vibration control of corrugated rolling mill. J Iron Steel Res Int 30(4):736–748

Hao L, Wu H, Wei DB, Cheng XW, Zhao JW, Luo SZ, Jiang LZ, Jiang ZY (2017) Wear and friction behaviour of high-speed steel and indefinite chill material for rolling ferritic stainless steels. Wear 376–377:1580–1585

Yan XD, Sun JL, Xiong S, Hou YQ (2017) Insights into the sliding wear behavior of a copper-steel pair with oils containing extreme-pressure additives. Wear 386–387:211–217

Chen JS, Li CS (2015) Prediction and control of thermal scratch defect on surface of strip in tandem cold rolling. J Iron Steel Res Int 22(2):106–114

Nagendramma P, Kaul S (2012) Development of ecofriendly/biodegradable lubricants: an overview. Renew Sustain Energy Rev 16(1):764–774

Azushima A, Xue WD, Yoshida Y (2009) Influence of lubricant factors on coefficient of friction and clarification of lubrication mechanism in hot rolling. ISIJ Int 49(6):868–873

Morshed A, Wu H, Jiang ZY (2021) A comprehensive review of water-based nanolubricants. Lubricants 9(9):89

Tomala A, Karpinska A, Werner WSM, Olver A, Störi H (2010) Tribological properties of additives for water-based lubricants. Wear 269(11):804–810

Da Rocha PGL, De Oliveira MGL, Lemos PVF, De Sousa CLA, Da Rocha LPG, De Almeida JAR, Da Silva JBA (2022) Tribological performances of cellulose nanocrystals in water-based lubricating fluid. J Appl Polym Sci 139(20):52167

Rahman MH, Warneke H, Webbert H, Rodriguez J, Austin E, Tokunaga K, Rajak DK, Menezes PL (2021) Water-based lubricants: development, properties, and performances. Lubricants 9(8):73

Sun JL, Zhang BT, Dong C (2017) Effects of ferrous powders on tribological performances of emulsion for cold rolling strips. Wear 376–377:869–875

Bao YY, Sun JL, Kong LH (2017) Tribological properties and lubricating mechanism of SiO2 nanoparticles in water-based fluid. IOP Conf Ser Mater Sci Eng 182(1):012025

He JQ, Sun JL, Meng YN, Pei Y (2020) Superior lubrication performance of MoS2-Al2O3 composite nanofluid in strips hot rolling. J Manuf Process 57:312–323

Mobarhan G, Zolriasatein A, Ghahari M, Jalili M, Rostami M (2022) The enhancement of wear properties of compressor oil using MoS2 nano-additives. Adv Powder Technol 33(7):103648

Guan JJ, Wu J, Gao C, Wang Y, Xu XF (2022) Tribological properties of water-based nanofluids prepared by multi-walled carbon nanotubes composites filled with sulfurised isobutylene. Lubr Sci 34(4):275–289

Chen L, Tu N, Wei QY, Liu T, Li CZ, Wang WB, Li JH, Lu HL (2022) Inhibition of cold-welding and adhesive wear occurring on surface of the 6061 aluminum alloy by graphene oxide/polyethylene glycol composite water-based lubricant. Surf Interface Anal 54(3):218–230

Zhang Z, Guo YB, Han F, Wang DG, Zhang SW (2021) Multilayer graphene for reducing friction and wear in water-based sand cleaning liquid. Wear 470–471:203619

He JQ, Sun JL, Yang FL, Meng YN, Jiang W (2022) Water-based Cu nanofluid as lubricant for steel hot rolling: experimental investigation and molecular dynamics simulation. Lubr Sci 34(1):30–41

Bao YY, Sun JL, Kong LH (2017) Effects of nano-SiO2 as water-based lubricant additive on surface qualities of strips after hot rolling. Tribol Int 114:257–263

Gara L, Zou Q (2012) Friction and wear characteristics of water-based ZnO and Al2O3 nanofluids. Tribol Trans 55(3):345–350

Zhang BM, Sun JL (2017) Tribological performances of multilayer-MoS2 nanoparticles in water-based lubricating fluid. IOP Conf Ser Mater Sci Eng 182(1):012023

Jiang GC, Guan WC, Zheng QX (2005) A study on fullerene-acrylamide copolymer nanoball-a new type of water-based lubrication additive. Wear 258(11):1625–1629

Kong LH, Sun JL, Bao YY, Meng YN (2017) Effect of TiO2 nanoparticles on wettability and tribological performance of aqueous suspension. Wear 376–377:786–791

Kao MJ, Lin CR (2009) Evaluating the role of spherical titanium oxide nanoparticles in reducing friction between two pieces of cast iron. J Alloy Compd 483(1):456–459

Ge XY, Xia YQ, Cao ZF (2015) Tribological properties and insulation effect of nanometer TiO2 and nanometer SiO2 as additives in grease. Tribol Int 92:454–461

Wu H, Jiang CY, Zhang JQ, Huang SQ, Wang LZ, Jiao SH, Huang H, Jiang ZY (2019) Oxidation behaviour of steel during hot rolling by using TiO2-containing water-based nanolubricant. Oxid Met 92(3–4):315–335

Wu H, Kamali H, Huo MS, Lin F, Huang SQ, Huang H, Jiao SH, Xing Z, Jiang ZY (2020) Eco-friendly water-based nanolubricants for industrial-scale hot steel rolling. Lubricants 8(11):1–16

Wu H, Jia FH, Li Z, Lin F, Huo M, Huang SQ, Sayyar S, Jiao SH, Huang H, Jiang ZY (2020) Novel water-based nanolubricant with superior tribological performance in hot steel rolling. Int J Extreme Manuf 2(2):025002

Huo MS, Wu H, Xie HB, Zhao JW, Su GQ, Jia FH, Li Z, Lin F, Li SL, Zhang HM, Jiang ZY (2020) Understanding the role of water-based nanolubricants in micro flexible rolling of aluminium. Tribol Int 151:106378

Wu H, Zhao JW, Xia WZ, Cheng XW, He AS, Yun JH, Wang LZ, Huang H, Jiao SH, Huang L, Zhang SQ, Jiang ZY (2017) A study of the tribological behaviour of TiO2 nano-additive water-based lubricants. Tribol Int 109:398–408

Jiao D, Zheng SH, Wang YZ, Guan RF, Cao BQ (2011) The tribology properties of alumina/silica composite nanoparticles as lubricant additives. Appl Surf Sci 257(13):5720–5725

Ma L, Zhao J, Zhang M, Jiang Z, Zhou C, Ma X (2022) Study on the tribological behaviour of nanolubricants during micro rolling of copper foils. Materials 15(7):2600

Luo JB, Wen SZ, Huang P (1996) Thin film lubrication. Part I. Study on the transition between EHL and thin film lubrication using a relative optical interference intensity technique. Wear 194(1):107–115

Plouraboué F, Boehm M (1999) Multi-scale roughness transfer in cold metal rolling. Tribol Int 32(1):45–57

Xia WZ, Zhao JW, Wu H, Jiao SH, Zhao XM, Zhang XM, Xu JZ, Jiang ZY (2018) Analysis of oil-in-water based nanolubricants with varying mass fractions of oil and TiO2 nanoparticles. Wear 396–397:162–171

Saffari HRM, Soltani R, Alaei M, Soleymani M (2018) Tribological properties of water-based drilling fluids with borate nanoparticles as lubricant additives. J Petrol Sci Eng 171:253–259

Wu H, Zhao JW, Cheng XW, Xia WZ, He AS, Yun JH, Huang SQ, Wang LZ, Huang H, Jiao SH, Jiang ZY (2018) Friction and wear characteristics of TiO2 nano-additive water-based lubricant on ferritic stainless steel. Tribol Int 117:24–38

Becker R (1998) Effects of strain localization on surface roughening during sheet forming. Acta Mater 46(4):1385–1401

Xia WZ, Zhao JW, Cheng XW, Sun JL, Wu H, Yan Y, Jiao SH, Jiang ZY (2017) Study on growth behaviour of oxide scale and its effects on tribological property of nano-TiO2 additive oil-in-water lubricant. Wear 376–377:792–802

Ma B, Tieu AK, Lu C, Jiang Z (2002) An experimental investigation of steel surface characteristic transfer by cold rolling. J Mater Process Technol 125–126:657–663

Funding

This research was supported by the National Natural Science Foundation of China (No. 51975398), the Central Government Guided Local Science and Technology Development Fund Project (Grant No. YDZJSX2021A006), and the Basic Research Program of Shanxi Province (No. 202103021223286).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethical approval

All procedures performed in studies involving human participants were in accordance with the ethical standards of the institutional and/or national research committee and with the 1964 Helsinki declaration and its later amendments or comparable ethical standards.

Consent to participate

Informed consent was obtained from all individual participants included in the study.

Consent for publication

The participant has consented to the submission of the case report to the journal.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ma, L., Lian, J., Ma, X. et al. A study on the tribological behavior of water-based nanolubricant during corrugated rolling of copper plates. Int J Adv Manuf Technol 129, 1513–1526 (2023). https://doi.org/10.1007/s00170-023-12286-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12286-0