Abstract

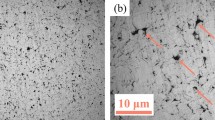

Producing bulk high-specific strength materials that replace steel airframe structures like stringers is the only optimistic alternative that can meet the future needs of the aviation sector. Stir casting, a prominent fabrication route to produce bulk materials, is employed in the current investigation to prepare aluminum composites reinforced with graphene nanoplatelets. However, the influence of dross on reinforcement infiltration into melt is unexplored by researchers and hence essential. The critical experimental insights reveal that dross hinders the nanoreinforcement incorporation into the melt; i.e., 25 to 40% of introduced GNPs are entrapped in dross. Moreover, superior mechanical behavior with an ultimate tensile strength (UTS) of 203 MPa led by a good uniform distribution of GNPs with no evidence of voids and clusters is observed for 1.5 wt.% GNP cast sample. Quantitative X-ray maps and EDS analysis reveal no iron contamination and their intermetallic compounds that degrade the strength of cast samples.

Similar content being viewed by others

Data availability

Data sharing not applicable to this article as no datasets were generated or analyzed during the current study.

References

Macke A, Schultz BF, Rohatgi P (2012) Metal matrix composites. Adv Mater Processes 170(3):19–23

Bhat A, Budholiya S, Aravind Raj S, Sultan MTH, Hui D, Md Shah AU, Safri SNA (2021) Review on nanocomposites based on aerospace applications. Nanotech Rev 10(1):237–253

Suryanarayanan K, Praveen R, Raghuraman S (2013) Silicon carbide reinforced aluminium metal matrix composites for aerospace applications: a literature review. Int J Innov Res Sci Eng Tech 2(11):6336–6344

Zhang X, Chen Y, Hu J (2018) Recent advances in the development of aerospace materials. Progress Aeros Sci 97:22–34

Liu Z, Han Q, Li J (2011) Ultrasound assisted in situ technique for the synthesis of particulate reinforced aluminum matrix composites. Comp Part B: Eng 42(7):2080–2084

Kotteda TK, Eshwar D, Balakrishna G, Kuchampudi SV, Prasad BD, Sadasivam S (2022) Experimental investigation on metal matrix nanocomposite: aluminium alloy 6061 and 7075 with SiC and fly ash. J Nanomater

Akbari MK, Baharvandi HR, Mirzaee O (2013) Fabrication of nano-sized Al2O3 reinforced casting aluminum composite focusing on preparation process of reinforcement powders and evaluation of its properties. Comp Part B: Eng 55:426–432

Akbari MK, Baharvandi HR, Mirzaee O (2013) Nano-sized aluminum oxide reinforced commercial casting A356 alloy matrix: evaluation of hardness, wear resistance and compressive strength focusing on particle distribution in aluminum matrix. Comp Part B: Eng 52:262–268

Amirkhanlou S, Niroumand B (2013) Microstructure and mechanical properties of Al356/SiCp cast composites fabricated by a novel technique. J Mater Eng Perform 22:85–93

Mazahery A, Shabani MO (2012) Characterization of cast A356 alloy reinforced with nano SiC composites. Transact Nonferrous Metals Soc China 22(2):275–280

Hanizam H, Salleh MS, Omar MZ, Sulong AB, Arif MAM (2020) Effects of hybrid processing on microstructural and mechanical properties of thixoformed aluminum matrix composite. J Alloys Compounds 836:155378

Fan Y, Wang L, Li J, Li J, Sun S, Chen F et al (2010) Preparation and electrical properties of graphene nanosheet/Al2O3 composites. Carbon 48(6):1743–1749

He T, Li J, Wang L, Zhu J, Jiang W (2009) Preparation and consolidation of alumina/graphene composite powders. Mater Transac 50(4):749–751

Lam CW, James JT, McCluskey R, Arepalli S, Hunter RL (2006) A review of carbon nanotube toxicity and assessment of potential occupational and environmental health risks. Critical Rev Toxic 36(3):189–217

Ghazanlou SI, Eghbali B (2021) Fabrication and characterization of GNPs and CNTs reinforced Al7075 matrix composites through the stir casting process. Int J Miner, Metall Mater 28:1204–1214

Zeng X, Teng J, Yu JG, Tan AS, Fu DF, Zhang H (2018) Fabrication of homogeneously dispersed graphene/Al composites by solution mixing and powder metallurgy. Int J Miner, Metall Mater 25:102–109

Yue H, Yao L, Gao X, Zhang S, Guo E, Zhang H et al (2017) Effect of ball-milling and graphene contents on the mechanical properties and fracture mechanisms of graphene nanosheets reinforced copper matrix composites. J All Compounds 691:755–762

Rashad M, Pan F, Liu Y, Chen X, Lin H, Pan R et al (2016) High temperature formability of graphene nanoplatelets-AZ31 composites fabricated by stir-casting method. J Magnes Alloys 4(4):270–277

Patil A, Nartu MSKKY, Ozdemir F, Banerjee R, Gupta RK, Borkar T (2021) Enhancement of the mechanical properties of graphene nanoplatelet (GNP) reinforced nickel matrix nanocomposites. Mater Sci Eng: A 817:141324

Srivastava AK, Sharma B, Saju BR, Shukla A, Saxena A, Maurya NK (2020) Effect of graphene nanoparticles on microstructural and mechanical properties of aluminum based nanocomposites fabricated by stir casting. World J Eng 17(6):859–866

Azizi Z, Rahmani K, Taheri-Behrooz F (2022) The influence of graphene nanoplatelets addition on the electrical and mechanical properties of pure aluminum used in high-capacity conductors. Metals 12(11):1883

Prakash PB, Raju KB, Venkatasubbaiah K, Manikandan N (2018) Microstructure analysis and evaluation of mechanical properties of Al 7075 GNP’s composites. Mater Today: Proceed 5(6):14281–14291

Sita Rama Raju K, Rama Murthy Raju P, Rajesh S, Raju VR, Ghosal P (2016) An experimental and micrographical investigation on aluminum nano metal matrix composites. J Comp Mater 50(26):3627–3641

Sajjadi SA, Ezatpour HR, Beygi H (2011) Microstructure and mechanical properties of Al–Al2O3 micro and nano composites fabricated by stir casting. Mater Sci Eng: A 528(29-30):8765–8771

Valibeygloo N, Azari Khosroshahi R, Taherzadeh Mousavian R (2013) Microstructural and mechanical properties of Al-4.5 wt% Cu reinforced with alumina nanoparticles by stir casting method. Int J Miner, Metall Mater 20:978–985

Kotteda TK, Kumar M, Kumar P, Chekuri RBR (2022) Metal matrix nanocomposites: future scope in the fabrication and machining techniques. Int J Advanc Manufact Tech:1–19

Zhang DD, He XY, Liu Y, Li Gao Y, Geng R (2022) Nanoparticles reinforced Al-matrix composites fabricated by combination of pre-distribution and deformation: a review. Mater Sci Tech 38(13):883–901

Mazahery A, Abdizadeh H, Baharvandi HR (2009) Development of high-performance A356/nano-Al2O3 composites. Mater Sci Eng: A 518(1-2):61–64

Raju KSR, Raju VR, Raju PRM, Ghosal P (2015) Launching particle to constant reinforcement ratio as a parameter for improving the nanoreinforcement distribution and tensile strength of aluminum nanometal matrix composites. Int J Mater Res 106(8):909–914

Raju KSR, Raju VR, Raju PRM, Rajesh S, Partha G (2016) Enhancement of the mechanical properties of an aluminum metal matrix nanocomposite by the hybridization technique. J Mater Res Tech 5(3):241–249

Suryanarayana C, Al-Aqeeli N (2013) Mechanically alloyed nanocomposites. Progress Mater Sci 58(4):383–502

Carpenter DT, Watanabe M, Barmak K, Williams DB (1999) Low-magnification quantitative X-ray mapping of grain-boundary segregation in aluminum–4 wt.% copper by analytical electron microscopy. Microsc Microanal 5(4):254–266

Taylor JA (2004) The effect of iron in Al-Si casting alloys. In: In 35th Australian foundry institute national conference, vol 31. Australian Foundry Institute (AFI), Adelaide, South Australia, pp 148–157

Munir K, Wen C, Li Y (2020) Graphene nanoplatelets-reinforced magnesium metal matrix nanocomposites with superior mechanical and corrosion performance for biomedical applications. J Magnes Alloys 8(1):269–290

Dzuong L, Löffler H, Thang NQ, Tri HM (1987) The effect of manganese additions on the structure changes proceeding in rapidly solidified Al-Cu alloys. Crys Res Tech 22(8):1031–1039

Tseng CJ, Lee SL, Tsai SC, Cheng CJ (2002) Effects of manganese on microstructure and mechanical properties of A206 alloys containing iron. J Mater Res 17(9):2243–2250

Shabestari SG (2004) The effect of iron and manganese on the formation of intermetallic compounds in aluminum–silicon alloys. Mater Sci Eng: A 383(2):289–298

Author information

Authors and Affiliations

Contributions

TKK wrote the original draft and worked on the software. MK worked on the software. TKK and MK defined the methodology, reviewed, and edited the manuscript. PK supervised the work. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Consent to participate

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kotteda, T.K., Kumar, M. & Kumar, P. Experimental insights and micrographical investigation on graphene nanoplatelet–reinforced aluminum cast composites. Int J Adv Manuf Technol 131, 2707–2718 (2024). https://doi.org/10.1007/s00170-023-12270-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12270-8