Abstract

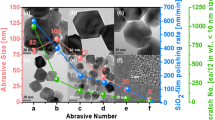

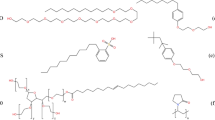

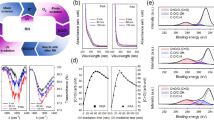

Chemical mechanical polishing (CMP) is a committed step in the manufacturing of integrated circuits, especially in the fabrication process of shallow trench isolation (STI) structures. Ceria (CeO2) slurry is widely used in the STI CMP process, while it is vulnerable to causing surface defects owing to particle agglomeration, such as scratches and abrasive residues. Furthermore, CeO2 slurry faces the challenge of low polishing removal selectivity between silicon dioxide (SiO2) and silicon nitride (Si3N4) surfaces. In this study, we investigated the effects of various non-ionic surfactants and different pH levels in CeO2-based slurries on material removal rates, removal selectivity, and surface qualities of polished wafers. Two of the studied non-ionic surfactants that make CeO2 slurries disperse better were selected through sedimentation experiments, which were polyethylpyrrolidone (PVP-K30) and polyethylene glycol, respectively. Subsequently, polishing experiments and atomic force microscopy characterization tests were conducted to illustrate the effects of the selected surfactants at different pH conditions. To further explore the underlying mechanism, the reaction of surfactants on SiO2 and Si3N4 wafers was explained using surface adsorption tests, thermogravimetry experiments, zeta potential measurements, and chemical valence bond structure analysis. As a result, it can be concluded that the performance of ceria slurries used in STI CMP process can be improved by the addition of non-ionic surfactant PVP-K30.

Similar content being viewed by others

References

Kang HG, Park HS, Paik U et al (2011) Effects of abrasive particle size and molecular weight of poly(acrylic acid) in ceria slurry on removal selectivity of SiO2/Si3N4 films in shallow trench isolation chemical mechanical planarization. J Mater Res 22(3):777–787

Kwak D, Oh S, Kim J et al (2021) Study on the effect of ceria concentration on the silicon oxide removal rate in chemical mechanical planarization. Colloids Surf, A 610:125670

Myong KK, Byun J, Choo MJ et al (2021) Direct and quantitative study of ceria-SiO2 interaction depending on Ce3+ concentration for chemical mechanical planarization (CMP) cleaning. Mater Sci Semicond Process 122:105500

Linhart AN, Wortman-Otto KM, Keleher JJ (2021) Evaluation of a photosensitizer redox couple for oxide removal rate tunability in shallow trench isolation chemical mechanical planarization. ECS J Solid State Sci Technol 10(6):063001

Janos P, Ederer J, Pilarova V et al (2016) Chemical mechanical glass polishing with cerium oxide: effect of selected physico-chemical characteristics on polishing efficiency. Wear 362(363):114–120

Prasad YN, Ramanathan S (2006) Role of amino-acid adsorption on silica and silicon nitride surfaces during STI CMP. Electrochem Solid-State Lett 9(12):G337–G339

Cho CW, Kim SK, Paik U et al (2006) Atomic force microscopy study of the role of molecular weight of poly(acrylic acid) in chemical mechanical planarization for shallow trench isolation. J Mater Res 21(2):473–479

Veera PRD, Peddeti S, Babu SV (2009) Selective chemical mechanical polishing of silicon dioxide over silicon nitride for shallow trench isolation using ceria slurries. J Electrochem Soc 156(12):H936–H943

Praveen B, Manivannan R, Umashankar TD et al (2014) Abrasive and additive interactions in high selectivity STI CMP slurries. Microelectron Eng 114(feb):98–104

Manivannan R, Victoria SN, Ramanathan S (2010) Mechanism of high selectivity in ceria based shallow trench isolation chemical mechanical polishing slurries. Thin Solid Films 518(20):5737–5740

Suphantharida P, Osseo-Asare K (2004) Cerium oxide slurries in CMP. Electrophoretic mobility and adsorption investigations of ceria/sificate interaction. J Electrochem Soc (10):151

Kim S, So JH, Lee DJ et al (2008) Adsorption behavior of anionic polyelectrolyte for chemical mechanical polishing (CMP). J Colloid Interface Sci 319(1):48–52

Yu L, Liu WL, Zhang ZF et al (2015) Synthesis of colloid silica coated with ceria nano-particles with the assistance of PVP. Chinese Chemical Letters, Chinese Chemical Society 26(6):700–704

Zhang J, Meng Y, Tian Y et al (2015) Effect of concentration and addition of ions on the adsorption of sodium dodecyl sulfate on stainless steel surface in aqueous solutions. Colloids Surf. A Physicochem Eng Asp 484:408–415

Acknowledgements

The authors are thankful to the editors and reviewers.

Funding

The research was supported by Tsinghua University Initiative Scientific Research Program.

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. The material preparation, data collection, and analysis were performed by Lile Xie, and the first draft of the manuscript was written by Lifei Zhang. All authors commented on previous versions of the manuscript, and all authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This manuscript has not been published or presented elsewhere in part or in entirety and is not under consideration by another journal. We have read and understood your journal’s policies, and we believe that neither the manuscript nor the study violates any of these.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, L., Xie, L. & Lu, X. Enhancing ceria slurry performance for shallow trench isolation chemical mechanical polishing through non-ionic surfactant addition. Int J Adv Manuf Technol 128, 4997–5010 (2023). https://doi.org/10.1007/s00170-023-12254-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12254-8