Abstract

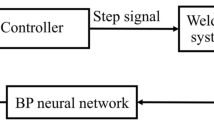

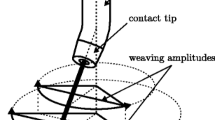

Oscillating parameters are key factors that affect sidewall penetration and restrain incomplete fusion in vertical oscillating arc all-position narrow-gap gas metal arc welding (NG-GMAW). In this regard, the back-propagation neural network (BPNN) optimized by gradient optimization algorithms is applied to describe the relationship between the oscillating parameters and the welding specifications. The welding current and speed were selected as the input parameters and the oscillating width and frequency as the output parameters. Experimental results show that the prediction accuracy reaches 86%. The performance tests show that the optimized parameters can be used to guide automatic welding in engineering applications. This article provides a foundation for the establishment of processing models for all-position NG-GMAW with a vertical oscillating arc.

Similar content being viewed by others

References

Feng JC, Rathod DW, Roy MJ, Francis JA, Guo W, Irvine NM, Vasileiou AN, Sun YL, Smith MC, Li L (2017) An evaluation of multipass narrow gap laser welding as a candidate process for the manufacture of nuclear pressure vessels. Int J Press Vessels Pip 157:43–50. https://doi.org/10.1016/j.ijpvp.2017.08.004

Moon HS, Ko SH, Kim JC (2009) Automatic seam tracking in pipeline welding with narrow groove. Int J Adv Manuf Technol 41:234–241. https://doi.org/10.1007/s00170-008-1474-9

Ding M, Tang XH, Lu FG, Shun Y (2011) Welding of quenched and tempered steels with high-spin arc narrow gap MAG system. Int J Adv Manuf Technol 55:527–533. https://doi.org/10.1007/s00170-010-3052-1

Xu WH, Lin SB, Fan CL, Yang CL (2015) Prediction and optimization of weld bead geometry in oscillating arc narrow gap all-position GMA welding. Int J Adv Manuf Technol 79:183–196. https://doi.org/10.1007/s00170-015-6818-7

Wang JY, Ren YS, Yang F, Guo HB (2007) Novel rotation arc system for narrow gap mag welding. Sci Technol Weld Join 12:505–507. https://doi.org/10.1179/174329307X213756

Ebrahimi A, Kleijn CR, Richardson IM (2021) A simulation-based approach to characterise melt-pool oscillations during gas tungsten arc welding. Int J Heat Mass Transfer 164:120535. https://doi.org/10.1016/j.ijheatmasstransfer.2020.120535

Park JH, Kim SH, Moon HS, Kim MH (2019) Influence of gravity on molten pool behavior and analysis of microstructure on various welding positions in pulsed gas metal arc welding. Appl Sci 9:4626. https://doi.org/10.3390/app9214626

Qian K, Zhang YM (2014) Bilinear model predictive control of plasma keyhole pipe welding process. J Manuf Sci Eng 136:031002. https://doi.org/10.1115/1.4025337

Ai YW, Lei C, Cheng J, Mei J (2023) Prediction of weld area based on image recognition and machine learning in laser oscillation welding of aluminum alloy. Opt Lasers Eng 160:107258. https://doi.org/10.1016/j.optlaseng.2022.107258

Chang YS, Yue JF, Guo R, Liu WJ, Li LY (2020) Penetration quality prediction of asymmetrical fillet root welding based on optimized BP neural network. J Manuf Process 50:247–254. https://doi.org/10.1016/j.jmapro.2019.12.022

Wang HY, Zhang ZX, Liu LM (2021) Prediction and fitting of weld morphology of Al alloy-CFRP welding-rivet hybrid bonding joint based on GA-BP neural network. J Manuf Process 63:109–120. https://doi.org/10.1016/j.jmapro.2020.04.010

Tian L, Luo Y, Wang Y, Wu Y (2014) Prediction of transverse and angular distortions of gas tungsten arc bead-on-plate welding using artificial neural network. Mater Des 54:458–472. https://doi.org/10.1016/j.matdes.2013.08.082

Zhang YX, Gao XD, Seiji K (2015) Weld appearance prediction with BP neural network improved by genetic algorithm during disk laser welding. J Manuf Syst 34:53–59. https://doi.org/10.1016/j.jmsy.2014.10.005

Goodfellow I, Bengio Y, Courville A (2016) Deep learning. MIT Press, Boston. https://www.deeplearningbook.org

Qian N (1999) On the momentum term in gradient descent learning algorithms. Neural Netw 12:145–151. https://doi.org/10.1016/S0893-6080(98)00116-6

Nesterov Y (1983) A method for unconstrained convex minimization problem with the rate of convergence O (1/k^2). Doklady AN SSSR 269:543–547

Duchi J, Hazan E, Singer Y (2011) Adaptive subgradient methods for online learning and stochastic optimization. J Mach Learn Res 12:257–269

Zeiler MD (2012) ADADELTA An adaptive learning rate method. arXiv.22:1–6. https://doi.org/10.48550/arXiv.1212.5701

Funding

This research was supported by the project of Robot and intelligent equipment technology innovation team (Grant number [2022D14002]), Xinjiang Society and Technology Development Project (Grant number [690005]), and Study on droplet transition and molten pool behaviours in laser arc composite welding in overhead position (Grant number [XJUBSCX-201906]).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design. Material preparation, data collection and analysis were performed by Hongsheng Liu, Ruilei Xue, Jianping Zhou, and Yang Bao. The first draft of the manuscript was written by Hongsheng Liu, and all authors commented on previous versions of the manuscript. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Liu, H., Xue, R., Zhou, J. et al. Prediction of oscillating parameters of vertical oscillating arc all-position NG-GMAW based on optimized BPNN. Int J Adv Manuf Technol 128, 5237–5247 (2023). https://doi.org/10.1007/s00170-023-12238-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12238-8