Abstract

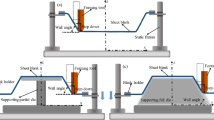

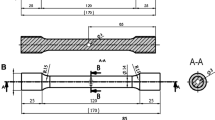

Single-point incremental forming (SPIF) is a technology that allows obtaining complex parts using a hemispherical end tool by applying a local deformation process in sheet metal. This dieless process presents the advantage of high formability limits and low cost. The increasing need for micro-components, namely, in the medical industry (implants and medical tools and accessories), has contributed to the development of the micro-single-point incremental forming (µ-SPIF) technique. However, this technique requires meeting certain challenges related to tool wear, resistance and precision of the manufactured parts, and increased formability. So, understanding the deformation and failure mechanisms in µ-SPIF is important to achieve improved formability. This paper is aimed at improving the predictions of the shear-modified GTN damage model by proposing an identification procedure for its numerous material parameters based on an inverse method coupling the numerical predictions with experimental results. The extended GTN model is first implemented into the finite element code Abaqus. The numerical approach is assessed through numerical simulations under shear and uniaxial tension loading. Then, a complete methodology is proposed to identify the set of material parameters using tensile and micro-single-point incremental forming (µ-SPIF) experimental results. The identification approach is based on the comparison of the numerical and experimental forces used to carry out the micro-incremental forming test with a pyramidal shape tool. To show the pertinence of the identification procedure, the numerical predictions of the modified GTN model with these material parameters are compared to the experimental results of µ-SPIF tests with different tool paths and geometrical forms. Finally, it is shown that the shear modification of the GTN model can predict the failure of sheets during metal forming.

Similar content being viewed by others

References

Duflou JR, Habraken A-M, Cao J, Malhotra R, Bambach M, Adams D, Jeswiet J (2018) Single point incremental forming: state-of-the-art and prospects. Int J Mater Form 11(6):743–773. https://doi.org/10.1007/s12289-017-1387-y

McClintock FA (1968) A criterion for ductile fracture by the growth of holes. J Appl Mech 35(2):363–371. https://doi.org/10.1115/1.3601204

Rice JR, Tracey DM (1969) On the ductile enlargement of voids in triaxial stress fields∗. J Mech Phys Solids 17(3):201–217. https://doi.org/10.1016/0022-5096(69)90033-7

Gurson AL (1977) Continuum theory of ductile rupture by void nucleation and growth: part I—yield criteria and flow rules for porous ductile media. J Eng Mater Technol 99(1):2–15. https://doi.org/10.1115/1.3443401

Tvergaard V (1981) Influence of voids on shear band instabilities under plane strain conditions. Int J Fract 17(4):389–407. https://doi.org/10.1007/BF00036191

Tvergaard V (1982) Influence of void nucleation on ductile shear fracture at a free surface. J Mech Phys Solids 30(6):399–425. https://doi.org/10.1016/0022-5096(82)90025-4

Tvergaard V, Needleman A (1984) Analysis of the cup-cone fracture in a round tensile bar. Acta Metall 32(1):157–169. https://doi.org/10.1016/0001-6160(84)90213-X

Besson J, Devillers-Guerville L, Pineau A (2000) Modeling of scatter and size effect in ductile fracture: application to thermal embrittlement of duplex stainless steels. Eng Fract Mech 67(2):169–190. https://doi.org/10.1016/S0013-7944(00)00056-4

Chen Z, Dong X (2009) The GTN damage model based on Hill’48 anisotropic yield criterion and its application in sheet metal forming. Comput Mater Sci 44(3):1013–1021. https://doi.org/10.1016/j.commatsci.2008.07.020

Kiran R, Khandelwal K (2014) Gurson model parameters for ductile fracture simulation in ASTM A992 steels: Gurson model parameters for ductile fracture simulation in ASTM A992 steels. Fatigue Fract Eng Mater Struct 37(2):171–183. https://doi.org/10.1111/ffe.12097

Benzerga AA, Leblond J-B, Needleman A, Tvergaard V (2016) Ductile failure modeling. Int J Fract 201(1):29–80. https://doi.org/10.1007/s10704-016-0142-6

Aldakheel F, Wriggers P, Miehe C (2018) A modified Gurson-type plasticity model at finite strains: formulation, numerical analysis and phase-field coupling. Comput Mech 62(4):815–833. https://doi.org/10.1007/s00466-017-1530-0

Ould Ouali M (2018) Relevance of incorporating cavity shape change in modelling the ductile failure of metals. Math Probl Eng 2018:1–9. https://doi.org/10.1155/2018/6454790

He Z, Zhu H, Hu Y (2021) An improved shear modified GTN model for ductile fracture of aluminium alloys under different stress states and its parameters identification. Int J Mech Sci 192:106081. https://doi.org/10.1016/j.ijmecsci.2020.106081

Bao Y, Wierzbicki T (2004) On fracture locus in the equivalent strain and stress triaxiality space. Int J Mech Sci 46(1):81–98. https://doi.org/10.1016/j.ijmecsci.2004.02.006

Lou Y, Huh H (2013) Evaluation of ductile fracture criteria in a general three-dimensional stress state considering the stress triaxiality and the lode parameter. Acta Mech Solida Sin 26(6):642–658. https://doi.org/10.1016/S0894-9166(14)60008-2

Xue L (2008) Constitutive modeling of void shearing effect in ductile fracture of porous materials. Eng Fract Mech 75(11):3343–3366. https://doi.org/10.1016/j.engfracmech.2007.07.022

Nahshon K, Hutchinson JW (2008) Modification of the Gurson model for shear failure. Eur J Mech A Solids 27(1):1–17. https://doi.org/10.1016/j.euromechsol.2007.08.002

Malcher L, Reis FJP, Andrade Pires FM, César de Sá JMA (2013) Evaluation of shear mechanisms and influence of the calibration point on the numerical results of the GTN model. Int J Mech Sci 75:407–422. https://doi.org/10.1016/j.ijmecsci.2013.08.008

Malcher L, Andrade Pires FM, César de Sá JMA (2014) An extended GTN model for ductile fracture under high and low stress triaxiality. Int J Plast 54:193–228. https://doi.org/10.1016/j.ijplas.2013.08.015

Kami A, Dariani B, Sadough VS, Comsa D-S, Banabic D (2014) Application of a GTN damage model to predict the fracture of metallic sheets subjected to deep-drawing. In: Proceedings of the Romanian Academy - Series A: mathematics, physics, technical sciences, information science 15:300–309

Kami A, Dariani BM, Sadough Vanini A, Comsa DS, Banabic D (2015) Numerical determination of the forming limit curves of anisotropic sheet metals using GTN damage model. J Mater Process Technol 216:472–483. https://doi.org/10.1016/j.jmatprotec.2014.10.017

Gatea S, Ou H, Lu B, McCartney G (2017) Modelling of ductile fracture in single point incremental forming using a modified GTN model. Eng Fract Mech 186:59–79. https://doi.org/10.1016/j.engfracmech.2017.09.021

Belouettar K, Mohand OO, Nasereddine Z, Sébastien T (2021) Investigation of the influence of incremental sheet forming process parameters using response surface methodology. Metall Res Technol 118(4):401. https://doi.org/10.1051/metal/2021039

Ying L, Wang D, Liu W, Wu Y, Hu P (2018) On the numerical implementation of a shear modified GTN damage model and its application to small punch test. IntJ Mater Form 11(4):527–539. https://doi.org/10.1007/s12289-017-1362-7

Achouri M, Germain G, Dal Santo P, Saidane D (2013) Numerical integration of an advanced Gurson model for shear loading: application to the blanking process. Comput Mater Sci 72:62–67. https://doi.org/10.1016/j.commatsci.2013.01.035

Achouri M, Germain G, Dal Santo P, Saidane D (2013) Experimental characterization and numerical modeling of micromechanical damage under different stress states. Mater Des 50:207–222. https://doi.org/10.1016/j.matdes.2013.02.075

Aguir H, Marouani H (2010) Gurson-Tvergaard-Needleman parameters identification using artificial neural networks in sheet metal blanking. IntJ Mater Form 3(S1):113–116. https://doi.org/10.1007/s12289-010-0720-5

Marouani H, Aguir H (2012) Identification of material parameters of the Gurson–Tvergaard–Needleman damage law by combined experimental, numerical sheet metal blanking techniques and artificial neural networks approach. IntJ Mater Form 5(2):147–155. https://doi.org/10.1007/s12289-011-1035-x

Abbassi F, Belhadj T, Mistou S, Zghal A (2013) Parameter identification of a mechanical ductile damage using Artificial Neural Networks in sheet metal forming. Mater Des 45:605–615. https://doi.org/10.1016/j.matdes.2012.09.032

Sun Q, Lu Y, Chen J (2020) Identification of material parameters of a shear modified GTN damage model by small punch test. Int J Fract 222(1–2):25–35. https://doi.org/10.1007/s10704-020-00428-4

Corigliano A, Mariani S, Orsatti B (2000) Identification of Gurson-Tvergaard material model parameters via Kalman filtering technique. I. Theory. Int J Fract 104(4):349–373. https://doi.org/10.1023/A:1007602106711

Springmann M, Kuna M (2005) Identification of material parameters of the Gurson–Tvergaard–Needleman model by combined experimental and numerical techniques. Comput Mater Sci 32(3–4):544–552. https://doi.org/10.1016/j.commatsci.2004.09.010

Springmann M, Kuna M (2006) Determination of ductile damage parameters by local deformation fields: measurement and simulation. Arch Appl Mech 75(10–12):775–797. https://doi.org/10.1007/s00419-006-0033-9

Muñoz-Rojas PA, Cardoso EL, Vaz M (2010) Parameter identification of damage models using genetic algorithms. Exp Mech 50(5):627–634. https://doi.org/10.1007/s11340-009-9321-y

Ghouati O, Gelin JC (1998) Identification of material parameters directly from metal forming processes. J Mater Process Technol 80–81:560–564. https://doi.org/10.1016/S0924-0136(98)00159-9

Ben Hmida R, Richard F, Thibaud S, Malécot P (2015) Elastic-plastic damage behavior identification in micro scale length from instrumented micro-single point incremental forming. 4M/ ICOMM2015 conf. Research Publishing, Milan, Italy, pp 230–233. https://doi.org/10.3850/978-981-09-4609-8_059

Hapsari G, Richard F, Ben Hmida R, Malécot P, Thibaud S (2018) Instrumented incremental sheet testing for material behavior extraction under very large strain: Information richness of continuous force measurement. Mater Des 140:317–331. https://doi.org/10.1016/j.matdes.2017.12.002

Aravas N (1987) On the numerical integration of a class of pressure-dependent plasticity models. Int J Numer Meth Eng 24(7):1395–1416. https://doi.org/10.1002/nme.1620240713

Zhang ZL (1995) Explicit consistent tangent moduli with a return mapping algorithm for pressure-dependent elastoplasticity models. Comput Methods Appl Mech Eng 121(1–4):29–44. https://doi.org/10.1016/0045-7825(94)00707-T

Ben Chabane N, Aguechari N, Ould Ouali M (2022) Study of the slant fracture in solid and hollow cylinders: experimental analysis and numerical prediction. Frattura ed Integrità Strutturale 17(63):169–189. https://doi.org/10.3221/IGF-ESIS.63.15

Nahshon K, Xue Z (2009) A modified Gurson model and its application to punch-out experiments. Eng Fract Mech 76(8):997–1009. https://doi.org/10.1016/j.engfracmech.2009.01.003

Ben Hmida R, Thibaud S, Gilbin A, Richard F (2013) Influence of the initial grain size in single point incremental forming process for thin sheets metal and microparts: experimental investigations. Mater Des 45:155–165. https://doi.org/10.1016/j.matdes.2012.08.077

Gréban F, Monteil G, Roizard X (2007) Influence of the structure of blanked materials upon the blanking quality of copper alloys. J Mater Process Technol 186(1–3):27–32. https://doi.org/10.1016/j.jmatprotec.2006.11.226

Hapsari G, Thibaud S, Richard F, Malécot P, Hmida RB, Bonnardot C (2020) Thin sheet behaviour identification by µ-InDef and identifiability analysis. Proc Manuf 47:1481–1489. https://doi.org/10.1016/j.promfg.2020.04.330

Voce E (1955) A practical strain-hardening function. Metallurgica 51:219–226

Oh C-K, Kim Y-J, Baek J-H, Kim Y-P, Kim W (2007) A phenomenological model of ductile fracture for API X65 steel. Int J Mech Sci 49(12):1399–1412. https://doi.org/10.1016/j.ijmecsci.2007.03.008

Nielsen KL, Tvergaard V (2009) Effect of a shear modified Gurson model on damage development in a FSW tensile specimen. Int J Solids Struct 46(3–4):587–601. https://doi.org/10.1016/j.ijsolstr.2008.09.011

Levenberg K (1944) A method for the solution of certain non-linear problems in least squares. Q Appl Math 2(2):164–168

Marquardt DW (1963) An algorithm for least-squares estimation of nonlinear parameters. J Soc Ind Appl Math 11(2):431–441

Richard F (1999) MIC2M: Modélisation et identification du comportement mécanique des matériaux. Université de Franche-Comté. http://mic2m.univ-fcomte.fr. Accessed 2022

Thibaud S, Ben Hmida R, Richard F, Malécot P (2012) A fully parametric toolbox for the simulation of single point incremental sheet forming process: numerical feasibility and experimental validation. Simul Model Pract Theory 29:32–43. https://doi.org/10.1016/j.simpat.2012.07.004

Brun R, Reichert P, Künsch HR (2001) Practical identifiability analysis of large environmental simulation models. Water Resour Res 37(4):1015–1030. https://doi.org/10.1029/2000WR900350

Richard F, Villars M, Thibaud S (2013) Viscoelastic modeling and quantitative experimental characterization of normal and osteoarthritic human articular cartilage using indentation. J Mech Behav Biomed Mater 24:41–52. https://doi.org/10.1016/j.jmbbm.2013.04.012

Ould Ouali M, Aberkane M (2009) Micromechanical modeling of the rolling of a A1050P aluminum sheet. IntJ Mater Form 2(1):25–36. https://doi.org/10.1007/s12289-008-0387-3

Torki ME, Tekoğlu C, Leblond J-B, Benzerga AA (2017) Theoretical and numerical analysis of void coalescence in porous ductile solids under arbitrary loadings. Int J Plast 91:160–181. https://doi.org/10.1016/j.ijplas.2017.02.011

Khan IA, Srivastava A, Needleman A, Benzerga AA (2021) An analysis of deformation and failure in rectangular tensile bars accounting for void shape changes. Int J Fract 230(1–2):133–156. https://doi.org/10.1007/s10704-021-00532-z

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Belouettar, K., Thibaud, S., Ould Ouali, M. et al. A numerical-experimental coupled method for the identification of model parameters from µ-SPIF test using a finite element updating method. Int J Adv Manuf Technol 128, 5195–5208 (2023). https://doi.org/10.1007/s00170-023-12210-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12210-6