Abstract

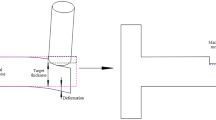

Micro-cutting processes, such as single-point diamond turning, are required for selective laser melting (SLM)–fabricated AlSi10Mg to machine optical mirrors. During the SLM process, cross contamination can often introduce the different metal particle into the AlSi10Mg workpiece, inducing various surface defects (concaves and scratches) on the micro-cutting machined surface. To find the micro-cutting mechanism of SLM AlSi10Mg containing the inside metal particle, the micro-cutting process was simulated using finite element analysis (FEA). The surface morphology formation mechanisms of the SLM AlSi10Mg containing the inside metal particle during the micro-cutting process were investigated. A scratch was created on the AlSi10Mg surface when the tool was at the upper part of the inside metal particle. A concave was formed due to the entire removal of the inside metal particle when the tool acted at the lower part of the particle. The proposed model was proven efficient and accurate by verifying the above mechanism with the machined surface morphologies. This paper provides a FEA example for the micro-cutting process of alloy matrix containing the inside metal particle.

Similar content being viewed by others

Data availability

The authors confirm that the data and material supporting the findings of this study are available within the article.

Code availability

Not applicable.

References

Amerongen AV, Rietjens J, Campo J, Dogan E, Dingjan J, Nalla R, Caron J, Hasekamp O (2018) SPEXone: a compact multi-angle polarimeter. Proc of SPIE 10(1117/12):2535940

Kim T, Yu ES, Bae YG, Lee J, Kim IS, Chung S, Lee SY, Ryu YS (2020) Asymmetric optical camouflage: tuneable reflective colour accompanied by the optical Janus effect. Light Sci Appl 9:175. https://doi.org/10.1038/s41377-020-00413-5

Li HF, Liu XQ, Lyu C, Gorbaciova J, Wen LL, Shan GG, Wyatt PB, Ye HQ, Gillin WP (2020) Enhanced 1.54-μm photo- and electroluminescence based on a perfluorinated Er(III) complex utilizing an iridium(III) complex as a sensitizer. Light Sci Appl 9:32. https://doi.org/10.1038/s41377-020-0266-3

Atkins C, Feldman C, Brooks D, Watson S, Cochrane W, Roulet M, Hugot E, Beardsley M, Harris M, Spindloe C, Alcock SG, Nistea IT, Morawe C, Perrin F (2018) Topological design of lightweight additively manufactured mirrors for space. Proc of SPIE 10(1117/12):2313353

Hilpert E, Hartung J, Risse S, Eberhardt R, Tünnermann A (2018) Precision manufacturing of a lightweight mirror body made by selective laser melting. Precis Eng 53:310–317. https://doi.org/10.1016/j.precisioneng.2018.04.013

Montazeri M, Yavari R, Rao P, Boulware P (2018) In-process monitoring of material cross-contamination in laser powder bed fusion. J Manuf Sci Eng 140(11):111001. https://doi.org/10.1115/1.4040543

Brandão AD, Gerard R, Gumpinger J, Beretta S, Makaya A, Pambaguian L, Ghidini T (2017) Challenges in additive manufacturing of space parts: powder feedstock cross-contamination and its impact on end products. Materials 10(5):522. https://doi.org/10.3390/ma10050522

Atkins C, Brzozowsk W, Dobson N, Milanova M, Todd S, Pearson D, Bourgenot C, Brooks D, Snell R, Sun W, Cooper P, Alcock SG, Nistea IT (2019) Additively manufactured mirrors for CubeSats. Proc of SPIE 10(1117/12):2528119

Zhang J, Wang C, Qu H, Guan H, Wang H, Zhang X, Xie X, Wang H, Zhang K, Li L (2022) Design and fabrication of an additively manufactured aluminum mirror with compound surfaces. Materials 15(20):7050. https://doi.org/10.3390/ma15207050

Pramanik A, Zhang LC, Arsecularatne JA (2007) An FEM investigation into the behavior of metal matrix composites: tool–particle interaction during orthogonal cutting. Int J Mach Tool Manuf 47(10):1497–1506. https://doi.org/10.1016/j.ijmachtools.2006.12.004

Chen X, Chen L, Chen H, Song B, Zhao Y, Yu T, Zhao J (2022) Meso-scale numerical simulation and experimental verification of single grain grinding Tic–Fe composites. Ceram Int 48(9):12299–12310. https://doi.org/10.1016/j.ceramint.2022.01.091

Du J, Zhang H, He W, Ma J, Ming W, Cao Y (2019) Simulation and experimental study on surface formation mechanism in machining of SiCp/Al composites. Appl Compos Mater 26(1):29–40. https://doi.org/10.1007/s10443-018-9681-5

Liu C, Ding W, Yu T, Yang C (2018) Materials removal mechanism in high-speed grinding of particulate reinforced titanium matrix composites. Precis Eng 51:68–77. https://doi.org/10.1016/j.precisioneng.2017.07.012

Fan Y, Wang T, Hao Z, Liu X, Gao S, Li R (2018) Surface residual stress in high speed cutting of superalloy Inconel718 based on multiscale simulation. J Manuf Process 31:480–493. https://doi.org/10.1016/j.jmapro.2017.12.011

Wang Y, Liao W, Yang K, Chen W, Liu T (2019) Investigation on cutting mechanism of SiCp/Al composites in precision turning. Int J Adv Manuf Technol 100(1):963–972. https://doi.org/10.1007/s00170-018-2650-1

Zhu Y, Kishawy HA (2005) Influence of alumina particles on the mechanics of machining metal matrix composites. Int J Mach Tool Manuf 45(4-5):389–398. https://doi.org/10.1016/j.ijmachtools.2004.09.013

Bai Y, Shi Z, Lee YJ, Wang H (2020) Optical surface generation on additively manufactured AlSiMg0.75 alloys with ultrasonic vibration-assisted machining. J Mater Process Technol 280:116597. https://doi.org/10.1016/j.jmatprotec.2020.116597

El-Gallab M, Sklad M (1997) Machining of Al/SiC particulate metal matrix composites part II: workpiece surface integrity. J Mater Process Technol 83:277–285. https://doi.org/10.1016/S0924-0136(98)00072-7

Ge YF, Xu JH, Yang H, Luo SB, Fu YC (2008) Workpiece surface quality when ultra-precision turning of SiCpAl composites. J Mater Process Technol 203:166–175. https://doi.org/10.1016/j.jmatprotec.2007.09.070

Kang P, Kim KH, Park HG, Nam S (2018) Mechanically reconfigurable architectured graphene for tunable plasmonic resonances. Light Sci Appl 7(1):1–9. https://doi.org/10.1038/s41377-018-0002-4

Luo J, Chu H, Peng R, Wang M, Li J, Lai Y (2021) Ultra-broadband reflectionless Brewster absorber protected by reciprocity. Light Sci Appl 10(1):1–10. https://doi.org/10.1038/s41377-021-00529-2

Subramanyam BV, Sekar KS (2018) Review of finite element analysis in machining processes. Adv Sci Eng Med 10(3-4):255–258. https://doi.org/10.1166/asem.2018.2121

Wang H, Deng W, Zhang T, Yao J, Wang S (2021) Development of elastoplastic-damage model of AlFeSi phase for aluminum alloy 6061. Metals 11(6):954. https://doi.org/10.3390/met11060954

Brandl E, Heckenberger U, Holzinger V, Buchbinder D (2012) Additive manufactured AlSi10Mg samples using Selective Laser Melting (SLM): microstructure, high cycle fatigue, and fracture behavior. Mater Design 34:159–169. https://doi.org/10.1016/j.matdes.2011.07.067

Popovich A, Sufiiarov V, Borisov E, Polozov IA (2015) Microstructure and mechanical properties of Ti-6Al-4V manufactured by SLM. Key Eng Mater 651:677–682. https://doi.org/10.4028/www.scientific.net/KEM.651-653.677

Abukhshim NA, Mativenga PT, Sheikh MA (2006) Heat generation and temperature prediction in metal cutting: a review and implications for high speed machining. Int J Mach Tool Manuf 46(7-8):782–800. https://doi.org/10.1016/j.ijmachtools.2005.07.024

Cai X, Pan C, Wang J, Zhang W, Fan Z, Gao Y, Xu P, Sun H, Li J, Yang W (2022) Mechanical behavior, damage mode and mechanism of AlSi10Mg porous structure manufactured by selective laser melting. J Alloys Compd 897:162933. https://doi.org/10.1016/j.jallcom.2021.162933

Wang Q, Liu Z, Wang B, Song Q, Wan Y (2016) Evolutions of grain size and micro-hardness during chip formation and machined surface generation for Ti-6Al-4V in high-speed machining. Int J Adv Manuf Technol 82(9):1725–1736. https://doi.org/10.1007/s00170-015-7508-1

Fathipour M, Hamedi M, Yousefi R (2013) Numerical and experimental analysis of machining of Al (20 vol% SiC) composite by the use of ABAQUS software. Materialwiss Werkst 44(1):14–20. https://doi.org/10.1002/mawe.201300959

Zhang Z, Men X, Pan Y, Wang Z, Shi Q, Fu X (2022) Research on simulation of SiCp/Al finite element cutting based on cohesive model. Mater Today Commun 32:103848. https://doi.org/10.1016/j.mtcomm.2022.103848

Chen Y, Chen S, Li L (2010) Influence of interfacial reaction layer morphologies on crack initiation and propagation in Ti/Al joint by laser welding–brazing. Mater Design 31(1):227–233. https://doi.org/10.1016/j.matdes.2009.06.029

Huang J, Liu Y, Liu S, Guan Z, Yu X, Wu H, Yu S, Fan D (2020) Process of welding-brazing and interface analysis of lap joint Ti-6Al-4v and aluminum by plasma arc welding. J Manuf Process 61(1):396–407. https://doi.org/10.1016/j.jmapro.2020.11.017

Blessto B, Nair S, Sivaprasad K, Nagarajan D (2020) Replication of the Al/Ti metal intermetallic laminates using LS Dyna for tungsten alloy penetrator application. J Inst Eng India Ser D:1–7. https://doi.org/10.1007/s40033-020-00208-3

Fan X, Yuan M, Qin Q (2018) Failure mechanisms of Ti-Al3Ti metal-intermetallic laminate composites under high-speed impact. Rare Metal Mat Eng 47(9):2615–2620

Duan YH, Sun Y, Lu L (2013) Thermodynamic properties and thermal conductivities of TiAl3-type intermetallics in Al–Pt–Ti system. Comput Mater Sci 68:229–233. https://doi.org/10.1016/j.commatsci.2012.11.012

Ogloza AA, Decker DL, Archibald PC, O'Connor DA, Bueltmann ER (1989) Optical properties and thermal stability of single-point diamond-machined aluminum alloys. Proc of SPIE 10(1117/12):948069

Chen YL, Cai Y, Xu M, Shimizu Y, Ito S, Gao W (2017) An edge reversal method for precision measurement of cutting edge radius of single point diamond tools. Precis Eng 50:380–387. https://doi.org/10.1016/j.precisioneng.2017.06.012

Mishra V, Garg H, Karar V, Khan GS (2019) Ultra-precision diamond turning process. In: Kumar K, Zindani D, Kumari N, Davim JP (eds) Micro and nano machining of engineering materials. Springer Nature, Cham, Switzerland, pp 65–97

An C, Feng K, Wang W, Xu Q, Lei X, Zhang J, Yao X, Li H (2021) Interaction mechanism of thermal and mechanical field in KDP fly-cutting process. Micromachines 12(8):855. https://doi.org/10.3390/mi12080855

Acknowledgements

The authors gratefully acknowledge the great support from the National Natural Science Foundation of China (NSFC) (No. 62105244).

Funding

This work was supported by the National Natural Science Foundation of China (NSFC) (No. 62105244).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Complied with ethical standards.

Consent to participate

All authors agree to contribute the article.

Consent for publication

All authors agree to publish the article.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, Y., Yu, J., Wang, K. et al. Micro-cutting mechanism of selective laser melting AlSi10Mg containing inside metal particles based on finite element analysis. Int J Adv Manuf Technol 128, 4123–4137 (2023). https://doi.org/10.1007/s00170-023-12154-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12154-x