Abstract

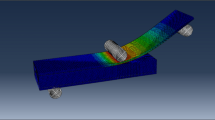

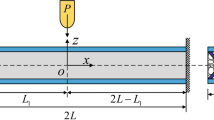

In the present work, face sheet/core debonding failure in the plastic forming of aluminum foam sandwich panel (AFSP) was numerically investigated. The mechanism of debonding failure during the forming process was analyzed first, and then, the bilinear cohesive zone model (CZM) was introduced to simulate the damage and the failure of adhesive layer, and the detailed parameters of CZM were characterized on the basis of the experiments and simulations of flatwise tensile and lap shear of AFSP. Extensive simulations on the plastic forming of spherical and saddle-shaped AFSPs were performed with a macroscopic equivalent AFSP model to gain further insight into the debonding behavior, and multi-point forming experiments were carried out and the deformed parts were scanned using X-ray to verify the face sheet/core debonding predictions using CZM. Furthermore, the effect of cohesive properties on face sheet/core debonding failure was researched, and the results reveal that debonding failure can be avoided by decreasing the initial stiffness of adhesive and increasing the maximum traction and the critical fracture energy of adhesive.

Similar content being viewed by others

Data availability

The publication-related datasets are available from the corresponding author upon reasonable request.

Code availability

Not applicable.

References

Ashby MF, Evans A, Fleck NA, Gibson LJ, Hutchinson JW, Wadley HNG (2000) Metal foams: a design guide. Butterworth Heimann, London

Banhart J, Seeliger HW (2008) Aluminium foam sandwich panels: manufacture, metallurgy and applications. Adv Eng Mater 10(9):793–802

Seeliger HW (2002) Manufacture of aluminum foam sandwich (AFS) components. Adv Eng Mater 4(10):753–758

Francisco GM (2016) Commercial applications of metal foams: their properties and production. Materials 9(2):85

Schwingel D, Seeliger HW, Vecchionacci C, Alwes D, Dittrich J (2007) Aluminium foam sandwich structures for space applications. Acta Astro 61(1-6):326–330

Liang XB, Cai ZY, Zhang X (2018) Forming characteristics analysis and springback prediction of bi-directional trapezoidal sandwich panels in the multi-point bend-forming. Int J Adv Manuf Technol 98(5-8):1709–1720

Cai ZY, Liang XB, Chen QM, Zhang X (2018) Numerical and experimental investigations on the formability of three-dimensional aluminum alloy sandwich panels with egg-box-like cores. Int J Adv Manuf Technol 99(1-4):387–397

Cai ZY, Zhang X, Liang XB (2018) Multi-point forming of sandwich panels with egg-box-like cores and failure behaviors in forming process: analytical models, numerical and experimental investigations. Mater Des 160:1029–1041

Liang XB, Cai ZY, Zhang X, Gao JX (2020) Plastic forming of the doubly curved surfaces of sandwich plates with bi-directionally trapezoidal cores of different sizes. Thin-Walled Struct 146:106188

Zhang X, Cai ZY, Liang XB, Gao JX (2020) Numerical investigation on the plastic forming of aluminum foam sandwich panel based on three-dimensional mesoscopic and macroscopic models. Int J Adv Manuf Technol 109(5-6):1431–1445

Zhang X, Chen QM, Gao JX, Wang MW, Zhang Y, Cai ZY (2021) Numerical study on the plastic forming of doubly curved surfaces of aluminum foam sandwich panel using 3d voronoi model. Metals 11(5):675

Zhang X, Chen QM, Cai ZY (2021) Prediction and prevention of fracture defect in plastic forming for aluminum foam sandwich panel. J Mater Res Technol-JMRT 15:1145–1154

Kabir K, Vodenitcharova T, Hoffman M (2014) Response of aluminium foam-cored sandwich panels to bending load. Compos Part B Eng 64:24–32

Styles M, Compston P, Kalyanasundaram S (2007) The effect of core thickness on the flexural behaviour of aluminium foam sandwich structures. Compos Struct 80(4):532–538

Sun GY, Wang ED, Zhang JT, Li SQ, Zhang Y, Li Q (2020) Experimental study on the dynamic responses of foam sandwich panels with different facesheets and core gradients subjected to blast impulse. Int J Impact Eng 135:103327

Rajhi W, Ayadi B, Khaliq A, Al-Ghamdi A, Al-shammrei S, Boulila A, Aichouni M (2021) Constitutive behavior and fracture of intermetallic compound layer in bimetallic composite materials: modeling and application to bimetal forming process. Mater Des 212:110294

Kukreja G, Narayanan RG (2019) Forming of adhesive-bonded sandwich sheets with a rubber pad. Metall Mater Trans A 50(5):2155–2168

Naik RK, Panda SK, Racherla V (2022) Failure analysis of metal-polymer-metal sandwich panels with wire mesh interlayers: finite element modeling and experimental validation. Compos Struct 280:114813

Ghiotti A, Bruschi S, Kain M, Lizzul L, Simonetto E, Tosello G (2021) Simultaneous bonding and forming of Mg fibre metal laminates at high temperature. J Manuf Process 72:105–114

Li MZ, Cai ZY, Sui Z, Yan QG (2002) Multi-point forming technology for sheet metal. J Mater Process Technol 129:333–338

De Moura MFSF, Goncalves JPM, Chousal JAG, Campilho RDSG (2008) Cohesive and continuum mixed-mode damage models applied to the simulation of the mechanical behaviour of bonded joints. Int J Adhes Adhes 28(8):419–426

Wang Z, Xian GJ (2022) Cohesive zone model prediction of debonding failure in CFRP-to-steel bonded interface with a ductile adhesive. Compos Sci Technol 230:109315

Zhang W, Huang YQ (2022) Three-dimensional numerical investigation of mixed-mode debonding of FRP-concrete interface using a cohesive zone model. Constr Build Mater 350:128818

ASTM C297/C297M-16 (2016) Standard test method for flatwise tensile strength of sandwich constructions. ASTM International, West Conshohocken, PA. https://doi.org/10.1520/C0297_C0297M-16

ASTM D1002-10 (2019) Standard test method for apparent shear strength of single-lap-joint adhesively bonded metal specimens by tension loading (metal-to-metal). ASTM International, West Conshohocken, PA. https://doi.org/10.1520/D1002-10R19

Dassault (2017) ABAQUS analysis user’s manual. Dassault Systems Simulia Corp

Liu JG, Liu W, Xue W (2013) Forming limit diagram prediction of AA5052/polyethylene/AA5052 sandwich sheets. Mater Des 46:112–120

Zhang L, Zhang J, Zhao GP (2015) Plastic Poisson’s ratio of closed-cell aluminum foams. Chin J Solid Mech 36(3):244–250

Cai ZY, Wang SH, Xu XD, Li MZ (2009) Numerical simulation for the multi-point stretch forming process of sheet metal. J Mater Process Technol 209(1):396–407

Zhang Q, Dean TA, Wang ZR (2006) Numerical simulation of deformation in multi-point sandwich forming. Int J Mach Tools Manuf 46(7-8):699–707

Funding

Financial support was provided by the National Science Foundation of China (Grant No. 51975248) and Graduate Innovation Fund of Jilin University (Grant No. 101832020CX140).

Author information

Authors and Affiliations

Contributions

Xi Zhang: conceptualization, methodology, writing-original draft preparation, experimental scheme design, validation. Zhong-yi Cai: writing-review and editing, funding acquisition. Jia-xin Gao: experiment design. Ming-wei Wang: validation.

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, X., Cai, Zy., Gao, Jx. et al. Numerical analysis of face sheet/core debonding failure in the plastic forming of aluminum foam sandwich panel. Int J Adv Manuf Technol 128, 2285–2300 (2023). https://doi.org/10.1007/s00170-023-12087-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12087-5