Abstract

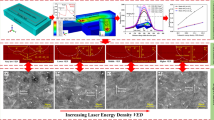

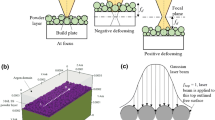

Reducing the defect density and improving the performance of selective laser melting-forming parts are significant for the development of selective laser melting (a great potential powder additive manufacturing method). Therefore, many methods like layer-by-layer laser remelting have been applied in the selective laser melting process. To investigate the influence of the layer-by-layer laser remelting process on the selective laser melting 316 L SS specimens, a three-dimension mesoscale remelting numerical simulation model in the single powder layer is established, and the microstructure and performance (surface quality, mechanical properties) are measured and analyzed with the different number of layer-by-layer laser remelting. The numerical simulation results show that the remelting process can effectively inhibit the defect. Nerversless, when the number of remelting is large, the over-melting phenomenon occurs, which is harmful to surface quality on the remelting surface. The experimental results also show that surface roughness, microhardness, ultimate strength, and strain can be effectively improved by controlling remelting times.

Similar content being viewed by others

Change history

04 October 2023

A Correction to this paper has been published: https://doi.org/10.1007/s00170-023-12387-w

References

Zhang Y, Liu F, Chen J, Yuan Y (2017) Effects of surface quality on corrosion resistance of 316L stainless steel parts manufactured via SLM. J Laser Appl 29(2):022306. https://doi.org/10.2351/1.4983263

Tabatabaeipour SM, Honarvar F (2010) A comparative evaluation of ultrasonic testing of AISI 316L welds made by shielded metal arc welding and gas tungsten arc welding processes. J Mater ProcessTech 210(8):1043–1050. https://doi.org/10.1016/j.jmatprotec.2010.02.013

Bae KC, Ha KS, Kim YH, Oak JJ, Lee W, Park YH (2020) Building direction dependence of wear resistance of selective laser melted AISI 316L stainless steel under high-speed tribological environment. Int J Adv Manuf Technol 108:2385–2396. https://doi.org/10.1007/s00170-020-05572-8

Yang X, Ma WJ, Ren YJ, Liu SF, Wang Y, Wang WL, Tang HP (2021) Subgrain microstructures and tensile properties of 316L stainless steel manufactured by selective laser melting. J Iron Steel Res Int 28:1159–1167. https://doi.org/10.1007/s42243-021-00561-x

Murr LE, Gaytan SM, Ramirez DA, Martinez E, Hernandez J, Amato KN, Shindo PW, Medina FR, Wicker RB (2012) Metal fabrication by additive manufacturing using laser and electron beam melting technologies. J Mater Sci Technol 28(1):1–14. https://doi.org/10.1016/S1005-0302(12)60016-4

Yap CY, Chua CK, Dong ZL, Liu ZH, Zhang DQ, Loh LE, Sing SL (2015) Review of selective laser melting: materials and applications. Appl Phys Rev 2(4):041101. https://doi.org/10.1063/1.4935926

Olakanmi EO, Cochrane RF, Dalgarno KW (2015) A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: processing, microstructure, and properties. Prog Mater Sci 74:401–477. https://doi.org/10.1016/j.pmatsci.2015.03.002

Zhang X, Yocom CJ, Mao B, Liao Y (2019) Microstructure evolution during selective laser melting of metallic materials: a review. J Laser Appl 31(3):031201. https://doi.org/10.2351/1.5085206

Fereiduni E, Ghasemi A, Elbestawi M (2020) Selective laser melting of aluminum and titanium matrix composites: recent progress and potential applications in the aerospace industry. Aerospace 7(6):77. https://doi.org/10.3390/aerospace7060077

Yadroitsev I, Krakhmalev P, Yadroitsava I (2014) Selective laser melting of Ti6Al4V alloy for biomedical applications: temperature monitoring and microstructural evolution. J Alloys Compd 583:404–409. https://doi.org/10.1016/j.jallcom.2013.08.183

Leal R, Barreiros FM, Alves L, Romeiro F, Vasco JC, Santos M, Marto C (2017) Additive manufacturing tooling for the automotive industry. The Int J Adv Manuf Technol 92:1671–1676. https://doi.org/10.1007/s00170-017-0239-8

Wang P, Deng L, Prashanth KG, Pauly S, Eckert J, Scudino S (2018) Microstructure and mechanical properties of Al-Cu alloys fabricated by selective laser melting of powder mixtures. J Alloys Compd 735:2263–2266. https://doi.org/10.1016/j.jallcom.2017.10.168

Song B, Dong S, Zhang B, Liao H, Coddet C (2012) Effects of processing parameters on microstructure and mechanical property of selective laser melted Ti6Al4V. Mater Des 35:120–125. https://doi.org/10.1016/j.matdes.2011.09.051

Luo H, Li XQ, Pan CL, He PJ, Zeng KL (2021) Microstructural evolution and mechanical properties of Alloy 718 fabricated by selective laser melting following different post-treatments. Rare Metals 40:3222–3234. https://doi.org/10.1007/s12598-020-01688-8

Zhou J, Han X, Li H, Liu S, Yi J (2021) Investigation of layer-by-layer laser remelting to improve surface quality, microstructure, and mechanical properties of laser powder bed fused AlSi10Mg alloy. Mater Des 210:110092. https://doi.org/10.1016/j.matdes.2021.110092

Lu P, Cheng-Lin Z, Hai-Yi L, Liang W, Tong L (2020) A new two-step selective laser remelting of 316L stainless steel: process, density, surface roughness, mechanical properties, microstructure. Mater Res Express 7(5):056503. https://doi.org/10.1088/2053-1591/ab8b86

Karimi J, Suryanarayana C, Okulov I, Prashanth KJ (2021) Selective laser melting of Ti6Al4V: effect of laser re-melting. Mater Sci Eng A 805:140558. https://doi.org/10.1016/j.msea.2020.140558

Qiu C, Wang Z, Aladawi AS, Kindi MA, Hatmi IA, Chen H, Chen L (2019) Influence of laser processing strategy and remelting on surface structure and porosity development during selective laser melting of a metallic material. Metall Mater Trans A 50:4423–4434. https://doi.org/10.1007/s11661-019-05348-0

Metelkova J, Ordnung D, Kinds Y, Van Hooreweder B (2021) Novel strategy for quality improvement of up-facing inclined surfaces of LPBF parts by combining laser-induced shock waves and in situ laser remelting. J Mater Process Technol 290:116981. https://doi.org/10.1016/j.jmatprotec.2020.116981

Lu P, Cheng-Lin Z, Liang W, Tong L, Xiao-Cheng L (2020) Research on mechanical properties and microstructure by selective laser melting of 316L stainless steel. Mater Res Express 6(12):1265h7. https://doi.org/10.1088/2053-1591/ab6b67

Pei W, Zhengying W, Zhen C, Junfeng L, Shuzhe Z, Jun D (2017) Numerical simulation and parametric analysis of selective laser melting process of AlSi10Mg powder. Appl Phys A 123:1–15. https://doi.org/10.1007/s00339-017-1143-7

Cao L (2021) Workpiece-scale numerical simulations of SLM molten pool dynamic behavior of 316L stainless steel. Comput Math Appl 96:209–228. https://doi.org/10.1016/j.camwa.2020.04.020

Acharya R, Sharon JA, Staroselsky A (2017) Prediction of microstructure in laser powder bed fusion process. Acta Mater 124:360–371. https://doi.org/10.1016/j.actamat.2016.11.018

Chen X, Mu W, Xu X, Liu W, Huang L, Li H (2021) Numerical analysis of double track formation for selective laser melting of 316L stainless steel. Appl Phys A 127:1–13. https://doi.org/10.1007/s00339-021-04728-x

Cao L (2021) Mesoscopic-scale numerical investigation including the influence of scanning strategy on selective laser melting process. Comput Mater Sci 189:110263. https://doi.org/10.1016/j.commatsci.2020.110263

Bayat M, Mohanty S, Hattel JH (2019) Multiphysics modelling of lack-of-fusion voids formation and evolution in IN718 made by multi-track/multi-layer L-PBF. Int J Heat Mass Transf 139:95–114. https://doi.org/10.1016/j.ijheatmasstransfer.2019.05.003

Sun Y, Jiang W, Xu G, Chen T, Mao L (2021) Influence of rough surface of deposited area on quality of powder spreading during selective laser melting: discrete element simulations. Chin J Theor App Mechan 53(12):3217–3227. https://doi.org/10.6052/0459-1879-21-399

Hirt CW, Nichols BD (1981) Volume of fluid (VOF) method for the dynamics of free boundaries. J Comput Phys 39(1):201–225. https://doi.org/10.1016/0021-9991(81)90145-5

Cook PS, Murphy AB (2020) Simulation of melt pool behaviour during additive manufacturing: Underlying physics and progress. Addit Manuf 31:100909. https://doi.org/10.1016/j.addma.2019.100909

Cao L (2021) Numerical investigation on molten pool dynamics during multi-laser array powder bed fusion process. Metall Mater Trans A 52:211–227. https://doi.org/10.1007/s11661-020-06076-6

Cao L (2019) Numerical simulation of the impact of laying powder on selective laser melting single-pass formation. Int J Heat Mass Transf 141:1036–1048. https://doi.org/10.1016/j.ijheatmasstransfer.2019.07.053

Tang C, Tan JL, Wong CH (2018) A numerical investigation on the physical mechanisms of single track defects in selective laser melting. Int J Heat Mass Transf 126:957–968. https://doi.org/10.1016/j.ijheatmasstransfer.2018.06.073

Li Y, Zhou K, Tor SB, Chua CK, Leong KF (2017) Heat transfer and phase transition in the selective laser melting process. Int J Heat Mass Transf 108:2408–2416. https://doi.org/10.1016/j.ijheatmasstransfer.2017.01.093

Liu B, Li BQ, Li Z (2019) Selective laser remelting of an additive layer manufacturing process on AlSi10Mg. Results in physics 12:982–988. https://doi.org/10.1016/j.rinp.2018.12.018

Li K, Zhao Z, Zhou H, Zhou H, Jin J (2020) Numerical analyses of molten pool evolution in laser polishing Ti6Al4V. J Manuf Process 58:574–584. https://doi.org/10.1016/j.jmapro.2020.08.045

Zhang M, Sun CN, Zhang X, Goh PC, Wei J, Hardacre D, Li H (2017) Fatigue and fracture behaviour of laser powder bed fusion stainless steel 316L: influence of processing parameters. Mater Sci Eng A 703:251–261. https://doi.org/10.1016/j.msea.2017.07.071

Kong D, Dong C, Wei S, Ni X, Zhang L, Li R, Wang L, Man C, Li X (2021) About metastable cellular structure in additively manufactured austenitic stainless steels. Addit Manuf 38:101804. https://doi.org/10.1016/j.addma.2020.101804

Pham MS, Dovgyy B, Hooper PA, Gourlay CM, Piglione A (2020) The role of side-branching in microstructure development in laser powder-bed fusion. Nat Commun 11(1):749. https://doi.org/10.1038/s41467-020-14453-3

Li J, Yang L, Zheng H, Jiang Z, Sui Z (2021) Influence of laser selection melting times on the surface properties of 316L stainless steel. Surf Technol 50(6):93–100

Bartolomeu F, Buciumeanu M, Pinto E, Alves N, Carvalho O, Silva FS, Miranda G (2017) 316L stainless steel mechanical and tribological behavior—a comparison between selective laser melting, hot pressing and conventional casting. Addit Manuf 16:81–89. https://doi.org/10.1016/j.addma.2017.05.007

Sadali MF, Hassan MZ, Ahmad F, Yahaya H, Rasid ZA (2020) Influence of selective laser melting scanning speed parameter on the surface morphology, surface roughness, and micropores for manufactured Ti6Al4V parts. J Mater Res 35(15):2025–2035. https://doi.org/10.1557/jmr.2020.84

Funding

This work was supported by the National Natural Science Foundation of China (Grant No. 51875152), the Anhui Province College Excellent Young Talents Fund Project (Grant No. gxyq2020034), Anhui Province Key Research and Development Program Project (202004a05020066, 202104a05020049), Anhui Province University Outstanding Youth Research Project (Project Approval Number: 2022AH020025), and Key Research Project of Natural Science of Anhui Provincial Colleges and Universities (Project Approval Number: 2022AH050257).

Author information

Authors and Affiliations

Contributions

All authors contributed to the study conception and design.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: In section 2.1 of the article, the Figure 3 image was inadvertently copied and pasted as Figure 4 image.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, X., Wen, K., Mu, W. et al. Effect of layer-by-layer laser remelting process on the microstructure and performance of selective laser melting 316L stainless steel. Int J Adv Manuf Technol 128, 2221–2236 (2023). https://doi.org/10.1007/s00170-023-12078-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12078-6