Abstract

Disassembly of e-waste has received significant attention over the past decades to extract value-added parts or components for recovery or reuse. It is imperative to develop automatic disassembly to replace human workers thus safeguarding them against the hazardous environment. Most scholars investigate the disassembly of e-waste from a technical perspective on laboratory scale. Few types of research related to its development track and scaled application are completed. This paper attempts to fill this gap by analyzing the disassembly of Waste Electrical and Electronic Equipment (WEEE) in a strategic perspective from manual operation, (semi)-automation to intelligent disassembly through a systematic literature review. The main barriers to automating the recycling industry lie in the high complexity and uncertainty of end-of-life (EOL) products that perplex the automatic handling and planning. Intelligent systems integrated in cognitive robots are helpful to handle the uncertainty through learning and revision processes. This work has three objectives: first, to map out what research has been carried out in the field of WEEE disassembly and the necessity for disassembly automation; second, to conduct a systematic literature review for the state of the art of automatic disassembly and discuss the barriers to its industrial application; third, to propose a perspective for integrating Industry 4.0 technologies with disassembly automation to promote flexibility and efficiency, providing a new scheme for future treatment of WEEE.

Similar content being viewed by others

Data availability

Data will be made available on request.

Change history

24 August 2023

A Correction to this paper has been published: https://doi.org/10.1007/s00170-023-12208-0

References

Kawai K, Tasaki T (2016) Revisiting estimates of municipal solid waste generation per capita and their reliability. J Mater Cycles Waste Manag 18(1):1–13

Fu J, Zhang H, Zhang A, Jiang G (2018) E-waste recycling in China: a challenging field. Environ Sci Technol 52(12):6727–6728

Sankhla MS, Kumari M, Nandan M, et al. (2016) Effect of electronic waste on environmental & human health-a review[J]. IOSR J. Environ. Sci. Toxicol. Food Technol 10(09):98–104.

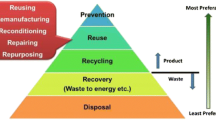

Genovese A, Acquaye AA, Figueroa A, Koh SCL (2017) Sustainable supply chain management and the transition towards a circular economy: evidence and some applications. Omega 66:344–357

Cole C, Gnanapragasam A, Cooper T, Singh J (2019) An assessment of achievements of the WEEE Directive in promoting movement up the waste hierarchy: experiences in the UK. Waste Manag 87:417–427

Schäfer J, Singer R, Hofmann J, Fleischer J (2020) Challenges and solutions of automated disassembly and condition-based remanufacturing of lithium-ion battery modules for a circular economy. Procedia Manuf 43:614–619

Zeng X, Mathews JA, Li J (2018) Urban mining of e-waste is becoming more cost-effective than virgin mining. Environ Sci Technol 52(8):4835–4841

Poschmann H, Brüggemann H, Goldmann D (2020) Disassembly 4.0: a review on using robotics in disassembly tasks as a way of automation. Chemie Ingenieur Technik 92(4):341–359

Vanegas P, Peeters JR, Cattrysse D, Tecchio P, Ardente F, Mathieux F, Dewulf W, Duflou JR (2018) Ease of disassembly of products to support circular economy strategies. Resour Conserv Recycl 135:323–334

Schoch K, Liedtke C, Bienge K (2021) Designing on the Basis of Recycling-Metallurgy Possibilities: Material-Specific Rules and Standards for “Anti-dissipative” products. Resources 10(1):5

Papaoikonomou K, Emmanouil C, Vasilato V, Diapouli E, Grigoratos T, Zafirakou A, Kungolos A (2018) PM10 and elemental concentrations in a dismantling plant for waste of electrical and electronic equipment in Greece. Aerosol Air Qual Res 18(6):1457–1469

Sarc R, Curtis A, Kandlbauer L, Khodier K, Lorber K, Pomberger R (2019) Digitalisation and intelligent robotics in value chain of circular economy oriented waste management–a review. Waste Manag 95:476–492

Tranfield D, Denyer D, Smart P (2003) Towards a methodology for developing evidence-informed management knowledge by means of systematic review. Br J Manag 14(3):207–222

Matsuto T, Jung CH, Tanaka N (2004) Material and heavy metal balance in a recycling facility for home electrical appliances. Waste Manag 24(5):425–436

Kopacek B (2016) Intelligent disassembly of components from printed circuit boards to enable re-use and more efficient recovery of critical metals. IFAC-PapersOnLine 49(29):190–195

Gu Z, Feng J, Han W, Wu M, Fu J, Sheng G (2010) Characteristics of organic matter in PM2.5 from an e-waste dismantling area in Taizhou, China. Chemosphere 80(7):800–806

Lau WKY, Liang P, Man YB, Chung SS, Wong MH (2014) Human health risk assessment based on trace metals in suspended air particulates, surface dust, and floor dust from e-waste recycling workshops in Hong Kong, China. Environ Sci Pollut Res 21(5):3813–3825

Cai H, Xu X, Zhang Y, Cong X, Lu X, Huo X (2019) Elevated lead levels from e-waste exposure are linked to sensory integration difficulties in preschool children. Neurotoxicology 71:150–158

Huo X, Peng L, Xu X, Zheng L, Qiu B, Qi Z, Zhang B, Han D, Piao Z (2007) Elevated blood lead levels of children in Guiyu, an electronic waste recycling town in China. Environ Health Perspect 115(7):1113–1117

http://japanese.china.org.cn/life/2013-06/17/content_29144078_3.htm

https://retroworks.blogspot.com/2018/01/smokescreen-in-africa-german.html

Chancerel P, Meskers CEM, Hagelüken C, Rotter VS (2009) Assessment of precious metal flows during preprocessing of waste electrical and electronic equipment. J Ind Ecol 13(5):791–810

Suzuki G, Kida A, Sakai S-I, Takigami H (2009) Existence state of bromine as an indicator of the source of brominated flame retardants in indoor dust. Environ Sci Technol 43(5):1437–1442

Fang W, Yang Y, Xu Z (2013) PM10 and PM2.5 and health risk assessment for heavy metals in a typical factory for cathode ray tube television recycling. Environ Sci Technol 47(21):12469–12476. Accessed 4 Dec 2022.

Julander A, Lundgren L, Skare L, Grandér M, Palm B, Vahter M, Lidén C (2014) Formal recycling of e-waste leads to increased exposure to toxic metals: an occupational exposure study from Sweden. Environ Int 73:243–251

Wang H, Han M, Yang S, Chen Y, Liu Q, Ke S (2011) Urinary heavy metal levels and relevant factors among people exposed to e-waste dismantling. Environ Int 37(1):80–85

Tan SY, Praveena SM, Abidin EZ, Cheema MS (2016) A review of heavy metals in indoor dust and its human health-risk implications. Rev Environ Health 31(4):447–456

Burns KN, Sayler SK, Neitzel RL (2019) Stress, health, noise exposures, and injuries among electronic waste recycling workers in Ghana. J Occup Med Toxicol 14(1):1

Cherubini A, Passama R, Crosnier A, Lasnier A, Fraisse P (2016) Collaborative manufacturing with physical human–robot interaction. Robot Comput-Integr Manuf 40:1–13

Sheet F (2021) The Raise the Wage Act of 2021

Helliwell JF, Huang H (2011) Well-being and trust in the workplace. J Happiness Stud 12(5):747–767

Jeong BY, Lee S, Lee JD (2016) Workplace accidents and work-related illnesses of household waste collectors. Saf Health Work 7(2):138–142

Low S (1988) Manufacturing automation protocol explained: the MAP report by Jack Hollingum. Published by IFS Ltd. 155pp.£ 75.00, Elsevier

Punkkinen H, Mroueh U-M, Wahlström M, Youhanan L, Stenmarck Å (2017) Critical metals in end-of-life products: recovery potential and opportunities for removal of bottlenecks of recycling. Nordic Council of Ministers

Chen SVWH (2015) Disassembly automation. Sustainable Production, Life Cycle Engineering and Management. Springer International Publishing

Vongbunyong S, Kara S, Pagnucco M (2013) Basic behaviour control of the vision-based cognitive robotic disassembly automation. Assem Autom 33(1):38–56

Seliger G, Keil T, Rebafka U, Stenzel (2001) Flexible disassembly tools. IEEE international symposium on electronics and the environment, pp 30–35

Ajwad SA, Iqbal J, Ullah MI, Mehmood A (2018) Optimal and robust control of multi DOF robotic manipulator: design and hardware realization. Cybern Syst 49(1):77–93

Seriani S, Gallina P, Scalera L, Lughi V (2018) Development of n-DoF preloaded structures for impact mitigation in cobots. J Mech Robot 10(5)

Büker U, Drüe S, Götze N, Hartmann G, Kalkreuter B, Stemmer R, Trapp R (2001) Vision-based control of an autonomous disassembly station. Robot Auton Syst 35(3):179–189

Chen WH, Foo G, Kara S, Pagnucco M (2020) Application of a multi-head tool for robotic disassembly. Procedia CIRP 90:630–635

Schumacher P, Jouaneh M (2013) A system for automated disassembly of snap-fit covers. Int J Adv Manuf Technol 69(9):2055–2069

Schmitt J, Haupt H, Kurrat M, et al. (2011) Disassembly automation for lithium-ion battery systems using a flexible gripper[C]//2011 15th International Conference on Advanced Robotics (ICAR). IEEE, 291–297.

Kaiser L, Schlotzhauer A, Brandstötter M (2018) Safety-related risks and opportunities of key design-aspects for Industrial Human-Robot Collaboration. Springer International Publishing, Cham

Wegener K, Chen WH, Dietrich F, Dröder K, Kara S (2015) Robot assisted disassembly for the recycling of electric vehicle batteries. Procedia CIRP 29:716–721

Wegener K, Andrew S, Raatz A, Dröder K, Herrmann C (2014) Disassembly of electric vehicle batteries using the example of the Audi Q5 hybrid system. Procedia CIRP 23:155–160

Alvarez-de-los-Mozos E, Renteria A (2017) Collaborative robots in e-waste management. Procedia Manuf 11:55–62

Megalingam RK, Bandhyopadhyay S, Vivek GV, Rahi MJ (2017) Hand gesture based wireless robotic arm control for agricultural applications. IOP Conf Ser: Mater Sci Eng 225:012204

Galparoli S, Caielli S, Rosa P, Terzi S (2021) Chapter 4 Semi-automated PCB disassembly Station. SpringerBriefs in Applied Sciences and Technology, P.S.T. Dr. Paolo Rosa, (ed)

Schluep M, Hagelüken C, Meskers C, Magalini F, Wang F, Müller E, Kuehr R, Maurer C, Sonnemann G (2009) Market potential of innovative e-waste recycling technologies in developing countries. in R’09 World Congress, Davos, Switzerland

Wang J, Guo J, Xu Z (2016) An environmentally friendly technology of disassembling electronic components from waste printed circuit boards. Waste Manag 53:218–224

Lee J, Kim Y, Lee J-C (2012) Disassembly and physical separation of electric/electronic components layered in printed circuit boards (PCB). J Hazard Mater 241–242:387–394

Rubin RS, de Castro MAS, Brandão D (2019) Disassembly of waste printed circuit boards using air heating and centrifugal force. Revista Eletrônica em Gestão, Educação e Tecnologia Ambiental 23:28

Borgida A, Mitchell T, Williamson KE (1986) Learning improved integrity constraints and schemas from exceptions in data and knowledge bases. In: Brodie ML, Mylopoulos J (eds) On Knowledge Base Management Systems: Integrating Artificial Intelligence and Database Technologies. Springer New York, New York, NY, pp 259–286

Zhao Y, Mooren E, Derbinsky N (2017) Reinforcement learning for modeling large-scale cognitive reasoning. in KEOD

Vongbunyong S, Kara S, Pagnucco M (2013) Application of cognitive robotics in disassembly of products. CIRP Ann 62(1):31–34

Jiang H, Yi J, Zhu X, Li Z (2018) Generating disassembly tasks for selective disassembly using ontology-based disassembly knowledge representation. Assem Autom 38(2):113–124

Dundar A, Jin J, Martini B, Culurciello E (2017) Embedded streaming deep neural networks accelerator with applications. IEEE Trans Neural Netw Learn Syst 28(7):1572–1583

Lu S, Wang B, Wang H, Chen L, Linjian M, Zhang X (2019) A real-time object detection algorithm for video. Comput Electr Eng 77:398–408

Redmon J, Divvala S, Girshick R, Farhadi A (2016) You only look once: unified, real-time object detection. in 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR)

Li X, Tian M, Kong S, Wu L, Yu J (2020) A modified YOLOv3 detection method for vision-based water surface garbage capture robot. Int J Adv Rob Syst 17(3):1729881420932715

Yamaguchi A, Atkeson CG (2019) Recent progress in tactile sensing and sensors for robotic manipulation: can we turn tactile sensing into vision? Adv Robot 33(14):661–673

Vongbunyong S, Kara S, Pagnucco M (2015) Learning and revision in cognitive robotics disassembly automation. Robot Comput-Integr Manuf 34:79–94

Bdiwi M, Rashid A, Putz M (2016) Autonomous disassembly of electric vehicle motors based on robot cognition. in 2016 IEEE International Conference on Robotics and Automation (ICRA)

Foo G, Kara S, Pagnucco M (2021) Screw detection for disassembly of electronic waste using reasoning and re-training of a deep learning model. Procedia CIRP 98:666–671

Marconi M, Palmieri G, Callegari M, Germani M (2018) Feasibility study and design of an automatic system for electronic components disassembly. J Manuf Sci Eng 141(2)

Supachai V, Maurice P, Sami K (2016) Vision-based execution monitoring of state transition in disassembly automation. Int J Autom Technol 10(5):708–716

Kirkman Richard, Voulvoulis Nikolaos (2017) The role of public communication in decision making for waste management infrastructure. Journal of environmental management 203:640–647

Gu F, Summers PA, Hall P (2019) Recovering materials from waste mobile phones: Recent technological developments. J Clean Prod 237:117657

Rujanavech C, Lessard J, Chandler S, Shannon S, Dahmus J, Guzzo R (2016) Liam - an innovation story. https://www.apple.com/environment/

Jackson L (2019) Environmental Progress Report. Apple: https://www.apple.com/environment/pdf/Apple_Environmental_Progress_Report_2020.pdf

Bogue R (2019) Robots in recycling and disassembly. Ind Robot: The Int J Robot Res Appl 46(4):461–466

Fulton K (2019) Apple expands global recycling programs, in Apple newsroom. https://www.apple.com/newsroom/2019/04/apple-expands-global-recycling-programs/

Schraft RD, Meyer C, Parlitz C, et al. Powermate-a safe and intuitive robot assistant for handling and assembly tasks[C]//Proceedings of the 2005 IEEE International Conference on Robotics and Automation. IEEE, 2005: 4074-4079.

Krüger J, Lien TK, Verl A (2009) Cooperation of human and machines in assembly lines. CIRP Ann 58(2):628–646

Renteria A, Alvarez E, Perez J (2010) A methodology to optimize the recycling process of WEEE: Case of television sets and monitors. Int J Adv Manuf Technol 54:789–800

Álvarez-de-los-Mozos E, Rentería-Bilbao A, Díaz-Martín F (2020) WEEE recycling and circular economy assisted by collaborative robots. Appl Sci 10(14):4800

Liu Q, Liu Z, Xu W, Tang Q, Zhou Z, Pham DT (2019) Human-robot collaboration in disassembly for sustainable manufacturing. Int J Prod Res 57(12):4027–4044. Accessed 2 Dec 2022.

Babiceanu RF, Seker R (2016) Big Data and virtualization for manufacturing cyber-physical systems: a survey of the current status and future outlook. Comput Ind 81:128–137. Accessed 2 Dec 2022.

Rocca R, Rosa P, Sassanelli C, Fumagalli L, Terzi S (2020) Integrating virtual reality and digital twin in circular economy practices: a laboratory application case. Sustainability 12(6):2286

Kerin M, Pham DT (2019) A review of emerging industry 4.0 technologies in remanufacturing. J Clean Prod 237:117805

Rosa P, Sassanelli C, Urbinati A, Chiaroni D, Terzi S (2020) Assessing relations between Circular Economy and Industry 4.0: a systematic literature review. Int J Prod Res 58(6):1662–1687

DeSmit Z, Elhabashy AE, Wells LJ, Camelio JA (2017) An approach to cyber-physical vulnerability assessment for intelligent manufacturing systems. J Manuf Syst 43:339–351

Monostori L, Kádár B, Bauernhansl T, Kondoh S, Kumara S, Reinhart G, Sauer O, Schuh G, Sihn W, Ueda K (2016) Cyber-physical systems in manufacturing. CIRP Ann 65(2):621–641

Lee J, Bagheri B, Kao H-A (2015) A cyber-physical systems architecture for Industry 4.0-based manufacturing systems. Manuf Lett 3:18–23

Asghari P, Rahmani AM, Javadi HHS (2019) Internet of Things applications: a systematic review. Comput Netw 148:241–261

Miorandi D, Sicari S, De Pellegrini F, Chlamtac I (2012) Internet of Things: vision, applications and research challenges. Ad Hoc Netw 10(7):1497–1516

Chen Y (2012) Challenges and opportunities of Internet of Things. in 17th Asia and South Pacific Design Automation Conference

Xie Y, Zhang Y, Cai Y (2019) Virtual reality engine disassembly simulation with natural hand-based interaction. In: Cai Y, van Joolingen W, Walker Z (eds) VR, Simulations and Serious Games for Education. Springer Singapore, Singapore, pp 121–128

Wang XV, Wang L (2019) Digital twin-based WEEE recycling, recovery and remanufacturing in the background of Industry 4.0. Int J Prod Res 57(12):3892–3902

Bayram B, İnce G (2018) Advances in robotics in the era of Industry 4.0. In: Ustundag A, Cevikcan E (eds) Industry 4.0: Managing The Digital Transformation. Springer International Publishing, Cham, pp 187–200

Tadapaneni NR (2018) Cloud computing: opportunities and challenges. Available at SSRN 3563342

Kumar A, Shankar R, Choudhary A, Thakur LS (2016) A big data MapReduce framework for fault diagnosis in cloud-based manufacturing. Int J Prod Res 54(23):7060–7073

Trigueros-Preciado S, Pérez-González D, Solana-González P (2013) Cloud computing in industrial SMEs: identification of the barriers to its adoption and effects of its application. Electron Mark 23(2):105–114

Wang XV, Wang L (2014) From Cloud manufacturing to Cloud remanufacturing: a Cloud-based approach for WEEE recovery. Manuf Lett 2(4):91–95

Xia K, Gao L, Chao KM, et al. A cloud-based disassembly planning approach towards sustainable management of WEEE[C]//2015 IEEE 12th International Conference on e-Business Engineering. IEEE, 2015: 203-208.

Bieller S (2020) World Robotics 2020. IFR International Federation of Robotics: https://ifr.org/img/office/World_Robotics_2020_Sales_Flyer.pdf

Microsoft Inc., S., WA (2020) 2019 Manufacturing Trends Report. Microsoft Inc., Seattle, WA

Yang S, Aravind MR, Kaminski J, Pepin H (2018) Opportunities for Industry 4.0 to support remanufacturing. Appl Sci 8(7):1177

Talavera JM, Tobón LE, Gómez JA, Culman MA, Aranda JM, Parra DT, Quiroz LA, Hoyos A, Garreta LE (2017) Review of IoT applications in agro-industrial and environmental fields. Comput Electron Agric 142:283–297

Benotsmane R, Kovács G, Dudás L (2019) Economic, social impacts and operation of smart factories in Industry 4.0 focusing on simulation and artificial intelligence of collaborating robots. Soc Sci 8(5):143

Xia K, Gao L, Wang L, Li W, Chao K-M (2015) A semantic information services framework for sustainable WEEE management toward cloud-based remanufacturing. J Manuf Sci Eng 137(6)

Funding

This work is funded by the Fundamental Research Funds for the Central Universities (Grant No. JZ2023HGTA0186, JZ2022HGQA0152). The financial support are greatly appreciated.

Author information

Authors and Affiliations

Contributions

Yingqi Lu: conceptualization, methodology, writing — original draft, writing — review and editing.

Weidi Pei: writing — review and editing.

Kaiyuan Peng: writing — review and editing, funding acquisition, project administration.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: Reference section has been inadvertently rearranged. References 101 – 104 should be listed as the references 24 – 27 in the final paper. References 24-100 should be listed as the references 28-104 in the final paper.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Lu, Y., Pei, W. & Peng, K. State of the art of automatic disassembly of WEEE and perspective towards intelligent recycling in the era of Industry 4.0. Int J Adv Manuf Technol 128, 2825–2843 (2023). https://doi.org/10.1007/s00170-023-12043-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12043-3