Abstract

CO2 laser glass polishing is an effective and widely studied method to acquire smooth and high-quality surfaces. In this study, the CO2 laser beam approximately 5 times larger than the width of the sample is used with slow scanning to polish a millimeter-sized silica rod sample. We have successfully reduced the Gaussian-filtered RMS surface roughness to 6.4 nm for an area of over 1.3 mm2. However, deformations are observed on the edges of the sample after the polishing process. This work focuses on the reasons and the approaches to overcome this deformation on the edges, presented for the first time in the literature. Experiments have revealed that these deformations result from the difference between the temperatures of the sample and its surrounding, not from the beam shape. A couple of approaches including masking, laser exposure timing, increasing the substrate temperature, and changing the substrate material, have been proposed to eliminate the deformations. Among these, replacing tungsten with silica as the substrate has been effective, and the direction of deformation is changed from upward to downward yielding smooth edges. The finite element method is used to further interpret the reason for this change with multiphysics like heat flux, heat transfer in solid and liquid, laminar flow, and deformed geometries. This work is believed to provide insight for future laser machining studies concerning the surface quality of millimeter and micron-scale optical components.

Similar content being viewed by others

References

Chkhalo NI et al (2016) Ion-beam polishing of fused silica substrates for imaging soft x-ray and extreme ultraviolet optics. Appl Opt 55(6):1249–1256

Gerhard C et al (2013) Polishing of optical media by dielectric barrier discharge inert gas plasma at atmospheric pressure. J Eur Opt Soc Rapid Publ 8:2013

Kim W-B et al (2015) Material removal of glass by magnetorheological fluid jet. Int J Precis Eng Manuf 16(4):629–637

Kanaoka M et al (2007) Figuring and smoothing capabilities of elastic emission machining for low-thermal-expansion glass optics. J Vac Sci Technol B 25(6):2110–2113

Laguarta F, Lupon N, Armengol J (1994) Optical glass polishing by controlled laser surface-heat treatment. Appl Opt 33(27):6508–6513

Hildebrand J et al (2011) Laser beam polishing of quartz glass surfaces. Phys Procedia 12:452–461

Weingarten C et al (2017) Laser polishing and laser shape correction of optical glass. J Laser Appl 29(1):011702

Yan Y et al (2013) CO2 laser peeling of Al2O3 ceramic and an application for the polishing of laser cut surfaces. J Eur Ceram Soc 33(10):1893–1905

Rao AB et al (2015) Parametric study of pulsed CO2 laser surface treatment of alumina ceramics. J Manuf Sci Prod 15:301–308

Lomer M et al (2007) A quasi-distributed level sensor based on a bent side-polished plastic optical fibre cable. Meas Sci Technol 18(7):2261

Chai Y et al (2018) Laser polishing of thermoplastics fabricated using fused deposition modelling. Int J Adv Manuf Technol 96(9):4295–4302

Ma CP, Guan YC, Zhou W (2017) Laser polishing of additive manufactured Ti alloys. Opt Lasers Eng 93:171–177

Pan A et al (2014) Fabrication of concave spherical microlenses on silicon by femtosecond laser irradiation and mixed acid etching. Opt Express 22(12):15245–15250

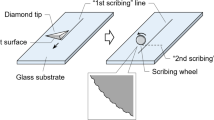

Choi H-K et al (2015) Formation of cylindrical micro-lens array on fused silica glass surface using CO2 laser assisted reshaping technique. Opt Laser Technol 75:63–70

Jiao F, Cheng K (2014) An experimental investigation on micro-milling of polymethyl methacrylate components with nanometric surface roughness. Proc Inst Mech Eng B J Eng Manuf 228(5):790–796

Feit M et al (2010) Densification and residual stress induced by CO(2) laser-based mitigation of SiO(2) surfaces. In: Laser-Induced Damage in Optical Materials, vol 2010, p 7842

Hildebrand J et al (2012) Advanced analysis of laser beam polishing of quartz glass surfaces. Phys Procedia 39:277–285

Matthews MJ et al (2015) Micro-shaping, polishing, and damage repair of fused silica surfaces using focused infrared laser beams. Adv Eng Mater 17(3):247–252

Weingarten C et al (2017) Laser polishing and 2PP structuring of inside microfluidic channels in fused silica. Microfluid Nanofluid 21(11):165

Desai JN (2009) Advances and processes in precision glass polishing techniques. Report of the University of Florida

Jung S, Lee PA, Kim BH (2016) Surface polishing of quartz-based microfluidic channels using CO2 laser. Microfluid Nanofluid 20(6):84

Zhao L et al (2022) Rapid CO2 laser processing technique for fabrication of micro-optics and micro-structures on fused silica materials. Proc Inst Mech Eng B J Eng Manuf 236(1-2):100–110

Schwarz S (2017) Fabrication of cylindrical lenses by combining ultrashort pulsed laser and CO2 laser. J Laser Micro Nanoeng 12:76–79

Lai MH et al (2017) CO2 Laser Applications in Optical Fiber Components Fabrication and Treatment: A Review. IEEE Sensors J 17(10):2961–2974

Zhou L et al (2019) Numerical and experimental investigation of morphological modification on fused silica using CO2 laser ablation. Mater 12(24):4109

Maniewski P, Laurell F, Fokine M (2021) Laser cladding of transparent fused silica glass using sub-μm powder. Opt Mater Express 11(9):3056–3070

Maniewski P, Laurell F, Fokine M (2022) Quill-free additive manufacturing of fused silica glass. Opt Mater Express 12(4):1480–1490

Weingarten C et al (2017) Glass processing with pulsed CO2 laser radiation. Appl Opt 56(4):777–783

Browar AEM et al (2021) A semi-analytical model for laser induced densification in fused silica at elevated temperatures. J Appl Phys 130(11):115302

Wang D et al (2020) Top-hat and Gaussian laser beam smoothing of ground fused silica surface. Opt Laser Technol 127:106141

Nowak KM, Baker HJ, Hall DR (2015) Analytical model for CO2 laser ablation of fused quartz. Appl Opt 54(29):8653–8663

Doualle T et al (2016) Thermo-mechanical simulations of CO2 laser–fused silica interactions. J Appl Phys 119(11):113106

Doualle T et al (2016) Comparison between fused silica of type II and III after surface heating with a CO2 laser. Applied Physics A 122(2):90

He T et al (2018) Super-smooth surface demonstration and the physical mechanism of CO2 laser polishing of fused silica. Opt Lett 43(23):5777–5780

Liu Y, Huang R, Madsen CK (2014) Design of a lens-to-channel waveguide system as a solar concentrator structure. Opt Express 22(S2):A198–A204

Dogan Y et al (2017) Fabrication of advanced glass light pipes for solar concentrators. In: SPIE Optifab. SPIE

Madsen CK et al (2018) Glass light pipes for solar concentration. In: Laser-based Micro-and Nanoprocessing XII, vol 10520. SPIE

Dogan Y, Madsen CK (2020) Optimization of ultrafast laser parameters for 3D micromachining of fused silica. Opt Laser Technol 123:105933

Buerhop C et al (1990) Glass surface treatment with excimer and CO 2 lasers. Appl Surf Sci 46(1):430–434

Hou Y et al (2013) Temperature-controlled directional spreading of water on a surface with high hysteresis. Npg Asia Mater 5:e77

Karapetsas G, Chamakos NT, Papathanasiou AG (2017) Thermocapillary droplet actuation: effect of solid structure and wettability. Langmuir 33(41):10838–10850

Sui Y (2014) Moving towards the cold region or the hot region? Thermocapillary migration of a droplet attached on a horizontal substrate. Phys Fluids 26(9):092102

Author information

Authors and Affiliations

Contributions

This work is a single-authored paper, and material preparation, data collection, and analysis were performed; the first draft of the manuscript was written by Yusuf Dogan.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dogan, Y. Experimental and numerical study of the CO2 laser-polishing edge effect on silica surface. Int J Adv Manuf Technol 128, 1483–1491 (2023). https://doi.org/10.1007/s00170-023-12015-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12015-7