Abstract

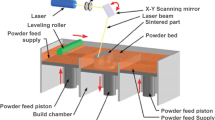

Manufacturing based on the selective laser sintering process has received a lot of attention in recent years because of its ability to produce complex parts without the need for support structures. Although this technology was created for the manufacture of prototypes, it is now applied to the manufacture of finished products. For this reason, the mechanical behavior and strength of the printed parts are of paramount importance. These are highly dependent on the process parameters which, if set at the right levels, can give better results. This paper focuses on the experimental study of the effect of four SLS parameters, such as laser power, scanning speed, layer thickness, and scan spacing on tensile strength, modulus of elasticity, and elongation at break. The specimens were printed at three angles, namely, 0°, 45°, and 90°, in order to study the influence of the orientation of the parts on their tensile properties. One hundred thirty-five polyamide 12 specimens were printed according to Taguchi’s L9 table. Subsequently, a series of tensile tests were conducted; the results obtained allowed to determine the strength and stiffness of the examined specimens. Then, validated regression models were generated. The obtained results will be interesting for a future development of SLS parts with better tensile strength, higher stiffness, and better ductility.

Similar content being viewed by others

Data Availability

Not applicable.

Code availability

Not applicable.

References

Wang X, Jiang M, Zhou Z, Gou J, Hui D (2017) 3D printing of polymer matrix composites: a review and prospective. Compos B Eng 110:442–458. https://doi.org/10.1016/j.compositesb.2016.11.034

Tofail SAM, Koumoulos EP, Bandyopadhyay A, Bose S, O’Donoghue L, Charitidis C (2018) Additive manufacturing: scientific and technological challenges, market uptake and opportunities. Mater Today 21(1):22–37. https://doi.org/10.1016/j.mattod.2017.07.001

Aslan B, Yildiz AR (2020) Optimum design of automobile components using lattice structures for additive manufacturing. Mater Test 323–338. https://doi.org/10.1515/mt-2020-0092

Andrzejewska A, Pejkowski Ł, Topolinski T (2019) Tensile and fatigue behavior of additive manufactured polylactide. 3D Print Addit Manuf 6:1–9. https://doi.org/10.1089/3dp.2017.0154

Hassanifard S, Hashemi SM (2020) On the strain-life fatigue parameters of additive manufactured plastic materials through fused filament fabrication process. Addit Manuf 32:100973. https://doi.org/10.1016/J.ADDMA.2019.100973

Obst P, Launhardt M, Drummer D, Osswald PV, Osswald TA (2018) Failure criterion for PA12 SLS additive manufactured parts. Addit Manuf 21:619–627. https://doi.org/10.1016/J.ADDMA.2018.04.008

Khosravani MR, Soltani P, Reinicke T (2021) Fracture and structural performance of adhesively bonded 3D printed PETG single lap joints under different printing parameters. Theor Appl Fract Mech 116:1030087. https://doi.org/10.1016/j.apsusc.2023.157217

Rasouli A, Azdast T, Mohammadzadeh H, Mihankhah P, Hasanzadeh R (2022) Morphological properties and mechanical performance of polylactic acid scaffolds fabricated by a novel fused filament fabrication/gas foaming coupled method. Int J Adv Manuf Technol 119:7463–7474. https://doi.org/10.1007/s00170-022-08743

Azdast T, Hasanzadeh R (2021) Polylactide scaffold fabrication using a novel combination technique of fused deposition modeling and batch foaming: dimensional accuracy and structural properties. Int J Adv Manuf Technol 114:1309–1321. https://doi.org/10.1007/s00170-021-06915-9

Abedini A, Asiyabi T, Campbell HR, Hassanzadeh R, Azdast T On fabrication and characteristics of injection molded ABS/Al2O3 nanocomposites. Int J Adv Manuf Technol. https://doi.org/10.1007/s00170-019-03311-2

Mihankhah P, Azdast T, Aghaiee S (2021) Fused filament fabrication of biodegradable polylactic acid reinforced by nanoclay as a potential biomedical material. J Thermoplast Compos Mater 36. https://doi.org/10.1177/08927057211044185

Martínez Krahmer D, Polvorosa R, López de Lacalle LN, Alonso-Pinillos U, Abate G, Riu F (2016) Alternatives for specimen manufacturing in tensile testing of steel plates. Exp Tech 40:1555–1565. https://doi.org/10.1007/s40799-016-0134-5

Rosso S, Meneghello R, Biasetto L, Grigolato L, Concheri G, Savio G (2020) In-depth comparison of polyamide 12 parts manufactured by multi jet fusion and selective laser sintering. Addit Manuf 36:101713. https://doi.org/10.1016/j.addma.2020.101713

Morgan R, Sutcliffe CJ, O’Neill W (2001) Experimental investigation of nanosecond pulsed Nd: YAG laser re-melted pre-placed powder beds. Rapid Prototyp J 7(3):159–172. https://doi.org/10.1108/13552540110395565

Charoo NA, Barakh Ali SF, Mohamed EM, Kuttolamadom MA, Ozkan T, Khan MA, Rahman Z (2020) Selective laser sintering 3D printing–an overview of the technology and pharmaceutical applications. Drug Dev Ind Pharm 46(6):869–877. https://doi.org/10.1080/03639045.2020.1764027

Wang RJ, Wang L, Zhao L, Liu Z (2007) Influence of process parameters on part shrinkage in SLS. Int J Adv Manuf Technol 33(5):498–504. https://doi.org/10.1007/s00170-006-0490-x

Pilipović A, Brajlih T, Drstvenšek I (2018) Influence of processing parameters on tensile properties of SLS polymer product. Polymers 10/11:1208. https://doi.org/10.3390/polym10111208

Dingal S, Pradhan TR, Sundar JK, Choudhury AR, Roy SK (2008) The application of Taguchi’s method in the experimental investigation of the laser sintering process. Int J Adv Manuf Technol 38(9):904–914. https://doi.org/10.1007/s00170-007-1154-1

Starr TL, Gornet TJ, Usher JS (2011) The effect of process conditions on mechanical properties of laser-sintered nylon. Rapid Prototyp J. https://doi.org/10.1108/13552541111184143

Stoia DI, Linul E, Marsavina L (2019) Influence of manufacturing parameters on mechanical properties of porous materials by selective laser sintering. Materials 12(6):871. https://doi.org/10.3390/ma12060871

Stoia DI, Marşavina L, Linul E (2019) Correlations between process parameters and outcome properties of laser-sintered polyamide. Polymers 11(11):1850. https://doi.org/10.3390/polym11111850

Günaydın AC, Yıldız AR, Kaya N (2022) Multi-objective optimization of build orientation considering support structure volume and build time in laser powder bed fusion. Mater Test. https://doi.org/10.1515/mt-2021-2075

Tang YS, Yang WH (1998) Design optimization of cutting parameters for turning operations based on the Taguchi method. J Mater Process Technol 84:122–129. https://doi.org/10.1016/S0924-0136(98)00079-X

Funding

The authors declare that no funds, grants, or other support were received during the preparation of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Faraj, Z., Zaki, S., Aboussaleh, M. et al. Influence of processing parameters on tensile properties of PA12 parts manufactured by selective laser sintering. Int J Adv Manuf Technol 128, 1115–1125 (2023). https://doi.org/10.1007/s00170-023-12009-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-12009-5