Abstract

The welding characteristics of 7075 aluminum alloy and DP980 dual-phase steel sheet were systematically studied by the friction plug-riveting spot welding technology. The effects of different welding parameters on the weld formation, tensile strength, and microstructure of welded joints were analyzed. The complete metallurgical joining interface was formed between the rivet and steel plate. A partial metallurgical joining interface was formed between the circumferential surface of the rivet shaft and the aluminum alloy close to the steel sheet. However, the position of the rivet head did not form a metallurgical joining with the aluminum alloy. During the welding process, the area of the rivet interface underwent severe plastic deformation by frictional heat and down pressure; thus, there was a violent interaction between the plastically deformed metal and the surrounding aluminum alloy. The molten aluminum infiltrated into the rivet at the most of sample joints. The penetration of aluminum had a negative effect on the shear load. The maximum shear load of the joint was 14.374 kN. There were two types of fractures: the internal fracture of the rivet and the fracture of the steel/steel friction interface. When the fracture mode was an internal fracture of the rivet, the shear load was generally greater than the steel/steel friction interface.

Similar content being viewed by others

References

Yang J, Oliveira JP, Li Y, Tan C, Gao C, Zhao Y, Yu Z (2022) Laser techniques for dissimilar joining of aluminum alloys to steels: a critical review. J Mater Process Technol 301:117443

Ma H, Qin G, Geng P, Ao Z, Chen Y (2022) Effect of intermetallic compounds on the mechanical property and corrosion behaviour of aluminium alloy/steel hybrid fusion-brazed welded structure. J Manuf Process 75:170–180

Li Y, Liu Y, Yang J (2020) First principle calculations and mechanical properties of the intermetallic compounds in a laser welded steel/aluminum joint. Opt Laser Technol 122:105875

Qiu R, Iwamoto C, Satonaka S (2009) Interfacial microstructure and strength of steel/aluminum alloy joints welded by resistance spot welding with cover plate. J Mater Process Technol 209:4186–4193

Azhari-Saray H, Sarkari-Khorrami M, Nademi-Babahadi A, Kashani-Bozorg SF (2020) Dissimilar resistance spot welding of 6061-T6 aluminum alloy/St-12 carbon steel using a high entropy alloy interlayer. Intermetallics 124:106876

Chen N, Wang H, Carlson BE, Sigler DR, Wang M (2017) Fracture mechanisms of Al/steel resistance spot welds in lap shear test. J Mater Process Technol 243:347–354

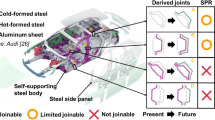

Karathanasopoulos N, Pandya KS, Mohr D (2021) An experimental and numerical investigation of the role of rivet and die design on the self-piercing riveting joint characteristics of aluminum and steel sheets. J Manuf Process 69:290–302

Abe Y, Kato T, Mori K (2009) Self-piercing riveting of high tensile strength steel and aluminium alloy sheets using conventional rivet and die. J Mater Process Technol 209:3914–3922

Mori K, Abe Y, Kato T (2014) Self-pierce riveting of multiple steel and aluminium alloy sheets. J Mater Process Technol 214:2002–2008

Karathanasopoulos N, Mohr D (2022) Strength and failure of self-piercing riveted aluminum and steel sheet joints: multi-axial experiments and modeling. J Adv Join Process 5:100107

Li P, Chen S, Dong H, Ji H, Li Y, Guo X, Yang G, Zhang X, Han X (2020) Interfacial microstructure and mechanical properties of dissimilar aluminum/steel joint fabricated via refilled friction stir spot welding. J Manuf Process 49:385–396

Chen K, Liu X, Ni J (2017) Keyhole refilled friction stir spot welding of aluminum alloy to advanced high strength steel. J Mater Process Technol 249:452–462

Takeoka N, Tsuchida T, Matsuda T, Ogura T, Ohashi R, Hirose A (2022) Analysis of mechanical properties of dissimilar material joint using scrubbing refill friction stir spot welding. J Adv Join Process 5:100112

Yu M, Zhao H, Zhang Z, Zhou L, Song X (2022) Friction surfacing assisted refilled friction stir spot welding of AA6061 alloy and Q235 steel. J Manuf Process 77:1–12

Huang T, Sato YS, Kokawa H, Miles MP, Kohkonen K, Siemssen B, Steel RJ, Packer S (2009) Microstructural evolution of DP980 steel during friction bit joining. Metall Mater Trans A 40:2994–3000

Miles MP, Kohkonen K, Packer S, Steel R, Siemssen B, Sato YS (2013) Solid state spot joining of sheet materials using consumable bit. Sci Technol Weld Joi 14:72–77

Miles MP, Feng Z, Kohkonen K, Weickum B, Steel R, Lev L (2013) Spot joining of AA 5754 and high strength steel sheets by consumable bit. Sci Technol Weld Joi 15:325–330

Lim YC, Squires L, Pan T, Miles M, Keum JK, Song G, Wang Y, Feng Z (2016) Corrosion behaviour of friction-bit-joined and weld-bonded AA7075-T6/galvannealed DP980. Sci Technol Weld Joi 22:455–464

Lim YC, Squires L, Pan T, Miles M, Song G, Wang Y, Feng Z (2015) Study of mechanical joint strength of aluminum alloy 7075-T6 and dual phase steel 980 welded by friction bit joining and weld-bonding under corrosion medium. Mater Des 69:37–43

Squires L, Lim YC, Miles MP, Feng Z (2015) Mechanical properties of dissimilar metal joints composed of DP 980 steel and AA 7075-T6. Sci Technol Weld Joi 20:242–248

Funding

The authors gratefully acknowledge financial support from the National Natural Science Foundation of China (no. 51875037).

Author information

Authors and Affiliations

Contributions

Li Jianyu: preparation, creation, and presentation of the published work, specifically writing the initial draft. Liu Yajia: conducting a research, specifically performing the experiments, and data collection. Gong Shuai: construction of theoretical friction model. Chen Shuhai: acquisition of the financial support for the project leading to this publication. Huang Jihua: development or design of methodology. Chen Shujun: oversight and leadership responsibility for the research activity planning and execution. Jiang Xiaoqing: critical review, commentary, and revision

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, J., Liu, Y., Gong, S. et al. Friction plug-riveting spot welding process of steel/aluminum dissimilar materials and the joint formation mechanism. Int J Adv Manuf Technol 128, 1243–1254 (2023). https://doi.org/10.1007/s00170-023-11999-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11999-6