Abstract

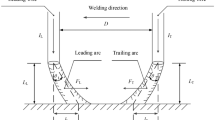

This paper aims to enhance the efficiency of the utilization of arc energy by adding ultrasonic and magnetic fields. A new welding method is proposed and named as ultrasonic-magnetic coaxial hybrid gas tungsten arc welding (U-M-GTAW). In this paper, the effect of tungsten extension and welding current on the arc characteristics under different welding methods and the effect of different welding methods on the 304 stainless steel weld formation were investigated. The arc shape changed significantly with increasing tungsten extension, and the addition of ultrasonic waves can increase the arc energy and stiffness. As the current increases, the arc area increases, and the degree of contraction and rotation of the arc decreases. Compared to the weld penetration of GTAW, U-GTAW and M-GTAW increased by 58.6% and 11.5%, respectively, while the weld penetration of U-M-GTAW decreased slightly. Compared with the weld width of GTAW, U-GTAW increased by 97.1%, M-GTAW increased by 44.5%, and U-M-GTAW increased the most by 123.8%.

Similar content being viewed by others

Data Availability

Not applicable

References

Afzal AA, Shaukat MM, Yilbas BS, Akhtar SS, Al-Badour F (2021) Life cycle assessment (LCA) of welded of AISI 304 stainless steel using laser beam welding (LBW), friction stir welding (FSW) and gas tungsten arc welding (GTAW). Lasers Eng 48(1-3):33–42

Liu GH, Liu MH, Yi YY, Zhang YP, Luo ZY, Xu L (2015) Activated flux tungsten inert gas welding of 8 mm-thick AISI 304 austenitic stainless steel. J Cent South Univ 22(3):800–805. https://doi.org/10.1007/s11771-015-2585-8

Ogundimu EO, Akinlabi ET, Erinosho MF (2018) Study on microstructure and mechanical properties of 304 stainless steel joints by Tig–Mig hybrid welding. Surf Rev Lett:25. https://doi.org/10.1142/s0218625x18500427

Chang Y, Yang D, Lai WEI, Lin LU (2011) Influence of magnetic controlled technology on formation of high-speed TIG welding. Trans China Weld Inst 32(3):49

Wang Y, Yu C, Lu H, Chen J (2020) Research status and future perspectives on ultrasonic arc welding technique. J Manuf Process 58:936–954. https://doi.org/10.1016/j.jmapro.2020.09.005

Pang XH, Wang T, Xiu SX, Feng DY, Jing H (2019) Study on arc mode and shape transformation in the arc motion stage between transverse magnetic field contacts. Contrib Plasma Physics 59(3):358–366. https://doi.org/10.1002/ctpp.201800086

Ning F, Cong W (2020) Ultrasonic vibration-assisted (UV-A) manufacturing processes: State of the art and future perspectives. J Manuf Process 51:174–190. https://doi.org/10.1016/j.jmapro.2020.01.028

Yang F, Zhou J, Ding R (2018) Ultrasonic vibration assisted tungsten inert gas welding of dissimilar magnesium alloys. J Mater Sci Technol 34(12):2240–2245. https://doi.org/10.1016/j.jmst.2018.06.009

Sun QJ, Lin SB, Yang CL, Zhao GQ (2009) Penetration increase of AISI 304 using ultrasonic assisted tungsten inert gas welding. Sci Technol Weld Join 14(8):765–767. https://doi.org/10.1179/136217109x12505932584772

Chen C, Fan C, Cai X, Liu Z, Lin S, Yang C (2019) Arc characteristics and weld appearance in pulsed ultrasonic assisted GTAW process. Results Phys:15. https://doi.org/10.1016/j.rinp.2019.102692

Fan Y, Sun Q, Yang C, Lin S (2009) TIG welding of the stainless steel 304 based on the ultrasonic vibration. Trans China Weld Inst 30(2):91–94

Baskoro AS, Tuparjono, Erwanto, Frisman S, Yogi A, Winarto (2014) Improvement of tungsten inert gas (TIG) welding penetration using the effect of electromagnetic field. Appl Mech Mater 493:558–563. https://doi.org/10.4028/www.scientific.net/AMM.493.558

Wu H, Chang Y, Lu L, Bai J (2017) Review on magnetically controlled arc welding process. Int J Adv Manuf Technol 91(9-12):4263–4273. https://doi.org/10.1007/s00170-017-0068-9

Li R, Yuan X, Zhang H, Yang J, Wu K, Li T, Wang G, Tao S, e. i. (2021) Effect of axial magnetic field on TIG welding–brazing of AA6061 aluminum alloy to HSLA350 steel. J Mater Res Technol 12:882–893. https://doi.org/10.1016/j.jmrt.2021.03.039

Wu H, Chang YL, Babkin A, Lee B (2020) The behavior of TIG welding arc in a high-frequency axial magnetic field. Weld World 65(1):95–104. https://doi.org/10.1007/s40194-020-01000-3

Chen C, Li W, Du W, Liu J, Zhang H (2022) Feasibility analysis of standing wave ultrasonic - axial magnetic field hybrid for controlling GTAW arc characteristics. J Manuf Process 80:187–195. https://doi.org/10.1016/j.jmapro.2022.06.005

Chen C, Li W, Fan C, Du W, Zhang H (2022) Understanding the changing mechanism of arc characteristics in ultrasound-magnetic field coaxial hybrid gas tungsten arc welding. Plasma Sci Technol. https://doi.org/10.1088/2058-6272/ac7cb9

Chen C, Fan C, Lin S, Zhou L, Yang C (2018) A new discovery of arc shape in pulsed ultrasonic wave assisted TIG welding. Phys Plasmas:25 (8). https://doi.org/10.1063/1.5044227

Sonia P, Jain JK, Saxena KK (2021) Influence of ultrasonic vibration assistance in manufacturing processes: a Review. Mater Manuf Process 36(13):1451–1475. https://doi.org/10.1080/10426914.2021.1914843

Xie W, Fan C, Yang C, Lin S, Zhang Y (2015) Characteristics of acoustic-controlled arc in ultrasonic wave-assisted arc. Acta Phys Sin 64(9). https://doi.org/10.7498/aps.64.095201

Chang Y, Yang X, Li D, Li D (2010) Arc shapes of TIG welding in a longitudinal magnetic field. Trans China Weld 31(4):49–52

Chen S, Meng D, Su Z, Jiang F, Lu Y (2014) Effects of longitudinal magnetic field on non-consumable gas shielded arc welding. Trans China Weld 35(10):5–8

Chen T, Zhang XN, Bai B, Xu ZM, Wang C, Xia WD (2015) Numerical study of DC argon arc with axial magnetic fields. Plasma Chem Plasma Process 35(1):61–74. https://doi.org/10.1007/s11090-014-9592-7

Jia S, Shi Z, Wang L (2014) Vacuum arc under axial magnetic fields: experimental and simulation research. J Phys D Appl Phys:47 (40). https://doi.org/10.1088/0022-3727/47/40/403001

Yin XQ, Gou JJ, Zhang JX, Sun JT (2012) Numerical study of arc plasmas and weld pools for GTAW with applied axial magnetic fields. J Phys D Appl Phys:45 (28). https://doi.org/10.1088/0022-3727/45/28/285203

Funding

This work was financially supported by the Fundamental Research Funds for the Central Universities (no. 2572022BF01) and the State Key Lab of Advanced Welding and Joining, Harbin Institute of Technology (grant no. AWJ-20M06).

Author information

Authors and Affiliations

Contributions

Not applicable

Corresponding author

Ethics declarations

Ethical approval

Not applicable

Consent to participate

Not applicable

Consent for publication

Not applicable

Competing interests

The authors declare no competing interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, W., Liu, J., Zhang, H. et al. Investigation of arc characteristics and weld formation in ultrasonic-magnetic coaxial hybrid GTAW. Int J Adv Manuf Technol 128, 1615–1628 (2023). https://doi.org/10.1007/s00170-023-11959-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11959-0