Abstract

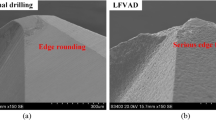

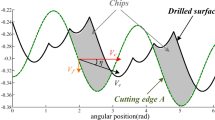

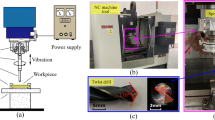

Carbon fiber–reinforced polymer (CFRP) and titanium alloy stacks play a significant role in the aerospace field to improve the mechanical properties of assembly components. Low-frequency vibration-assisted drilling (LFVAD) can realize the periodic contact and separation characteristic between tool and workpiece, thus pose a high potential for manipulating the machinability of CFRP/Ti stacks. In the present study, two types of drilling tools (polycrystalline diamond (PCD) tool and diamond-coated tool) are adopted, and tool wear behaviors are deeply evaluated during drilling CFRP/Ti stacks. Meanwhile, the specific influences of tool wear on the drilling performances are comprehensively analyzed under the LFVAD with minimum quantity lubrication (MQL). The results show that Ti-adhesion is observed for both drilling tools. Meanwhile, edge fracture is the key wear mode dominating for the PCD tool, and coating peeling is the main wear mode for the diamond-coated tool, with less Ti-adhesion. In addition, with the increasing number of drilled holes, the diamond-coated tool demonstrates better drilling performances with lower cutting force, better hole quality, and more hole-making number. The findings of this paper can contribute to providing a guidance for tool optimal selection in low-frequency vibration-assisted drilling of CFRP/Ti stacks with MQL.

Similar content being viewed by others

References

Wang FJ, Yin JW, Ma JW, Niu B (2018) Heat partition in dry orthogonal cutting of unidirectional CFRP composite laminates. Compos Struct 197:28–38. https://doi.org/10.1016/j.compstruct.2018.05.040

Wang FJ, Qian BW, Jia ZY, Fu R, Cheng D (2017) Secondary cutting edge wear of one-shot drill bit in drilling CFRP and its impact on hole quality. Compos Struct 178:341–352. https://doi.org/10.1016/j.compstruct.2017.04.024

Galos J (2020) Thin-ply composite laminates: a review. Compos Struct 236:111920. https://doi.org/10.1016/j.compstruct.2020.111920

Kolks G, Tserpes KI (2014) Efficient progressive damage modeling of hybrid composite/titanium bolted joints. Compos Part A-Appl S 56:51–63. https://doi.org/10.1016/j.compositesa.2013.09.011

Xu JY, Li C, Chen M, El Mansori M, Davim JP (2020) On the analysis of temperatures, surface morphologies and tool wear in drilling CFRP/Ti6Al4V stacks under different cutting sequence strategies. Compos Struct 234:111708. https://doi.org/10.1016/j.compstruct.2019.111708

Kuo CL, Soo SL, Aspinwall DK, Carr C, Bradley S, M’Saoubi R (2018) Development of single step drilling technology for multilayer metallic-composite stacks using uncoated and PVD coated carbide tools. J Manuf Process 31:286–300. https://doi.org/10.1016/j.jmapro.2017.11.026

Ezugwu EO, Bonney J, Da Silva RB, Cakir O (2007) Surface integrity of finished turned Ti-6Al-4V alloy with PCD tools using conventional and high pressure coolant supplies. Int J Mach Tool Manu 47(6):884–891. https://doi.org/10.1016/j.ijmachtools.2006.08.005

Che DM, Saxena I, Han PD, Guo P, Ehmann, KF (2014) Machining of carbon fiber reinforced plastics/polymers: a literature review. J Manuf Sci E-T Asme 136(3). https://doi.org/10.1115/1.4026526

Xu JY, Ji M, Chen M, Ren F (2019) Investigation of minimum quantity lubrication effects in drilling CFRP/Ti6Al4V stacks. Mater Manuf Process 34(12):1401–1410. https://doi.org/10.1080/10426914.2019.1661431

Park KH, Beal A, Kim D, Kwon P, Lantrip J (2014) A comparative study of carbide tools in drilling of CFRP and CFRP-Ti stacks. J Manuf Sci E-T Asme 136(1). https://doi.org/10.1115/1.4025008

Xu JY, El Mansori M (2017) Wear characteristics of polycrystalline diamond tools in orthogonal cutting of CFRP/Ti stacks. Wear 376:91–106. https://doi.org/10.1016/j.wear.2016.11.038

Lindvall R, Lenrick F, Persson H, M’Saoubi R, Stahl JE (2020) Performance and wear mechanisms of PCD and pcBN cutting tools during machining titanium alloy Ti6Al4V. Wear 454–455:203329. https://doi.org/10.1016/j.wear.2020.203329

Park KH, Beal A, Kim D, Kwon P, Lantrip J (2011) Tool wear in drilling of composite/titanium stacks using carbide and polycrystalline diamond tools. Wear 271(11–12):2826–2835. https://doi.org/10.1016/j.wear.2011.05.038

Xu JY, Ji M, Chen M, El Mansori M (2020) Experimental investigation on drilling machinability and hole quality of CFRP/Ti6Al4V stacks under different cooling conditions. Int J Adv Manuf Technol 109(5–6):1527–1539. https://doi.org/10.1007/s00170-020-05742-8

Park KH, Kwon P, Kim D (2012) Wear characteristic on BAM coated carbide tool in drilling of composite/titanium stack. Int J Precis Eng Man 13(7):1073–1076. https://doi.org/10.1007/s12541-012-0140-1

Braga DU, Diniz AE, Miranda GWA, Coppini NL (2002) Using a minimum quantity of lubricant (MQL) and a diamond coated tool in the drilling of aluminum-silicon alloys. J Mater Process Tech 122(1):127–138. https://doi.org/10.1016/S0924-0136(01)01249-3

Xu JY, Ji M, Davim JP, Chen M, El Mansori M, Krishnaraj V (2020) Comparative study of minimum quantity lubrication and dry drilling of CFRP/titanium stacks using TiAlN and diamond coated drills. Compo Struct 234:111727. https://doi.org/10.1016/j.compstruct.2019.111727

Yang HJ, Ding WF, Chen Y, Laporte S, Xu JH, Fu YC (2019) Drilling force model for forced low frequency vibration assisted drilling of Ti-6Al-4V titanium alloy. Int J Mach Tool Manu 146:103438. https://doi.org/10.1016/j.ijmachtools.2019.103438

Pecat O, Brinksmeier E (2014) Low damage drilling of CFRP/Titanium compound materials for fastening. Procedia CIRP 13:1–7. https://doi.org/10.1016/j.procir.2014.04.001

Pecat O, Brinksmeier E (2014) Tool wear analyses in low frequency vibration assisted drilling of CFRP/Ti6Al4V stack material. 6th Cirp Int Conf High Performance Cutting 142–147. https://doi.org/10.1016/j.procir.2014.03.050

Hussein R, Sadek A, Elbestawi MA, Attia MH (2021) The effect of MQL on tool wear progression in low-frequency vibration-assisted drilling of CFRP/Ti6Al4V stack material. J Manuf Mater Process 5(2):50. https://doi.org/10.3390/jmmp5020050

Hussein R, Sadek A, Elbestawi MA, Attia MH (2019) An investigation into tool wear and hole quality during low-frequency vibration-assisted drilling of CFRP/Ti6Al4V stack. J Manuf Mater Process 3(3):63. https://doi.org/10.3390/jmmp3030063

Li YX, Jiao F, Zhang ZQ, Feng ZB, Niu Y (2022) Research on entrance delamination characteristics and damage suppression strategy in drilling CFRP/Ti6Al4V stacks. J Manuf Process 76:518–531. https://doi.org/10.1016/j.jmapro.2022.02.018

Yan CR, Chen Y, Yang HJ, Qian N, Chen YJ, Guo N (2021) Machining performance of PCD drill in low-frequency vibration-assisted drilling of CFRP/Ti6Al4V stack: with special emphasis on the plowing behavior. Int J Adv Manuf Technol 116(7–8):2269–2283. https://doi.org/10.1007/s00170-021-07603-4

D’Orazio A, El Mehtedi M, Forcellese A, Nardinocchi A, Simoncini M (2017) Tool wear and hole quality in drilling of CFRP/AA7075 stacks with DLC and nanocomposite TiA1N coated tools. J Manuf Process 30:582–592. https://doi.org/10.1016/j.jmapro.2017.10.019

Xu JY, Huang XH, Chen M, Davim JP (2020) Drilling characteristics of carbon/epoxy and carbon/polyimide composites. Mater Manuf Process 35(15):1732–1740. https://doi.org/10.1080/10426914.2020.1784935

Xu JY, Li C, Chen M, Ren F (2019) A comparison between vibration assisted and conventional drilling of CFRP/Ti6Al4V stacks. Mater Manuf Process 34(10):1182–1193. https://doi.org/10.1080/10(426914),pp.1615085,2019

Sorrentino L, Esposito L, Bellini C (2017) A new methodology to evaluate the influence of curing overheating on the mechanical properties of thick FRP laminates. Compos B Eng 109:187–196. https://doi.org/10.1016/j.compositesb.2016.10.064

Li C, Xu JY, Chen M, An QL, El Mansori M, Ren F (2019) Tool wear processes in low frequency vibration assisted drilling of CFRP/Ti6Al4V stacks with forced air-cooling. Wear 426:1616–1623. https://doi.org/10.1016/j.wear.2019.01.005

Kolesnyk V, Peterka J, Alekseev O, Neshta A, Xu JY, Lysenko B, Sahul M, Martinovic J, Hrbal J (2022) Application of ANN for analysis of hole accuracy and drilling temperature when drilling CFRP/Ti alloy stacks. Materials 15:1940. https://doi.org/10.3390/ma15051940

Shao ZY, Jiang XG, Geng DX, Liu YH, Zhou ZH, Li SM, Zhang DY, Zheng W (2021) The interface temperature and its influence on surface integrity in ultrasonic-assisted drilling of CFRP/Ti stacks. Compos Struct 266:113803. https://doi.org/10.1016/j.compstruct.2021.113803

Xu JY, An QL, Chen M (2014) A comparative evaluation of polycrystalline diamond drills in drilling high-strength T800S/250F CFRP. Compos Struct 117:71–82. https://doi.org/10.1016/j.compstruct.2014.06.034

Xu JY, Zhou L, Chen M, Ren F (2019) Experimental study on mechanical drilling of carbon/epoxy composite-Ti6Al4V stacks. Mater Manuf Process 34(7):715–725. https://doi.org/10.1080/10426914.2019.1594275

Hussein R, Sadek A, Elbestawi MA, Attia MH (2018) Low-frequency vibration-assisted drilling of hybrid CFRP/Ti6Al4V stacked material. Int J Adv Manuf Technol 98(9–12):2801–2817. https://doi.org/10.1007/s00170-018-2410-2

Li J, Zou P, Qiao C, Dong L (2020) Temperature field distribution model in drilling of CFRP/Ti stacks structure. 4th Int Conf Electrical, Automation Mech Eng. https://doi.org/10.1088/1742-6596/1626/1/012041

Kim D, Ramulu M (2004) Drilling process optimization for graphite/bismaleimide-titanium alloy stacks. Compo Struct 63(1):101–114. https://doi.org/10.1016/S0263-8223(03)00137-5

Funding

This work is financially supported by the National Natural Science Foundation of China (grant no. 51875284).

Author information

Authors and Affiliations

Contributions

Dexiong Chen, Yan Chen, and Chaoren Yan contributed to the conception of the study. Chaoren Yan and Hai Lin performed the experiment. Dexiong Chen and Hai Lin performed the data analyses and wrote the manuscript. Yan Chen, Chaoren Yan, and Jiuhua Xu helped perform the analysis with constructive comments.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, D., Lin, H., Chen, Y. et al. Wear behaviors of PCD and diamond-coated tools during low-frequency vibration-assisted drilling CFRP/Ti stacks. Int J Adv Manuf Technol 128, 595–609 (2023). https://doi.org/10.1007/s00170-023-11899-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11899-9