Abstract

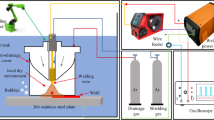

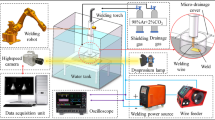

Local dry underwater backward median pulse MIG welding (LDU-BMPMIG) was proposed in this study. The effects of different backward median currents on welding process stability, weld forming, microstructure, and mechanical properties of weldments were investigated comprehensively. The results reveal that the backward median current waveform effectively improved the welding stability. By calculating the approximate entropy of the voltage signal during welding, it is proved that the welding stability increases first and then decreases with the increase of the backward median current. The welding process stability was the most satisfied with the backward median current of 200 A. The quality of weld formation was consistent with welding stability. LDU-BMPMIG weldments exhibited fewer macroscopic defects and better overall morphology compared with LDU-PMIG weldment. The weldment microstructure was mainly composed of γ-austenite and δ-ferrite with different morphologies. The satisfied stability of the welding process contributed to improving the microstructure uniformity. The variation trend of tensile strength for LDU-BMPMIG weldments was approximately kept consistent with welding process stability. The weldment prepared by 200 A showed considerable mechanical properties with minimal fluctuation, which reached 97.58% of maximum average tensile strength, which meant the most excellent compared to the others. The experimental results can improve the stability of local dry underwater welding and provide a theoretical basis and technical support for the application of underwater welding.

Similar content being viewed by others

Data availability

The datasets generated and/or analyzed during the current study are available from the corresponding authors on reasonable request.

References

Gao H, Jiao X, Zhou C, Shen Q, Yu Y (2011) Study on remote control underwater welding technology applied in nuclear power station. Proc Eng 15:4988–4993. https://doi.org/10.1016/j.proeng.2011.08.927

Vashishtha P, Wattal R, Pandey S, Bhadauria N (2022) Problems encountered in underwater welding and remedies- a review. Mater Today Proc 64:1433–1439. https://doi.org/10.1016/j.matpr.2022.04.634

Surojo E, Syah Putri EDW, Budiana EP, Triyono, (2020) Recent developments on underwater welding of metallic material. Proc Struct Integr 27:14–21. https://doi.org/10.1016/j.prostr.2020.07.003

Han LG, Wu XM, Chen GD, Wang ZM, Fan WY (2019) Local dry underwater welding of 304 stainless steel based on a microdrain cover. J Mater Process Tech 268:47–53. https://doi.org/10.1016/j.jmatprotec.2018.12.029

Wang ZM, Pei K, Han LG, Wu HD, Lin SB, Cai XY, Xu MJ, Zhang Q (2021) Effect of pulse frequency on droplet transfer and weld formation in local dry underwater welding. J Manuf Process 68:1726–1734. https://doi.org/10.1016/j.jmapro.2021.06.065

Liao HP, Zhang WX, Li XY, Pei K, Lin SB, Tian JY, Wang ZM (2022) Numerical simulation and experimental verification of droplet transfer during local dry underwater MIG welding process of SUS304. J Mater Res Technol 21:1960–1973. https://doi.org/10.1016/j.jmrt.2022.10.040

Liao HP, Zhang WX, Li XY, Pei K, Lin SB, Tian JY, Wang ZM (2022) Effect of pulse current on droplet transfer behavior and weld formation of 304 stainless steel in local dry underwater pulse MIG welding. Int J Adv Manuf Tech 122(2):869–879. https://doi.org/10.1007/s00170-022-09938-y

Guo N, Cheng Q, Fu YL, Du YP, Zhang X, Feng JC (2019) Investigation on the mass transfer control, process stability and welding quality during underwater pulse current FCAW for Q235. J Manuf Process 46:317–327. https://doi.org/10.1016/j.jmapro.2019.08.022

Reza Tabrizi T, Sabzi M, Mousavi Anijdan SH, Eivani AR, Park N, Jafarian HR (2021) Comparing the effect of continuous and pulsed current in the GTAW process of AISI 316L stainless steel welded joint: microstructural evolution, phase equilibrium, mechanical properties and fracture mode. J Mater Res Technol 15:199–212. https://doi.org/10.1016/j.jmrt.2021.07.154

Wu KY, Zhan JT, Cao XW, Zeng M, Ding N (2020) Metal transfer of aluminum alloy double-wire pulsed GMAW with a median waveform. J Mater Process Tech 286:116761. https://doi.org/10.1016/j.jmatprotec.2020.116761

Xu J, Ma Y, Wang L, Zhang Y, Lu X (2022) Numerical investigation on the influence of current waveform on droplet transfer in pulsed gas metal arc welding. Vacuum 203:111230. https://doi.org/10.1016/j.vacuum.2022.111230

Wu J, Wang Z, Lin S, Xie Z, Xu M, Tian J, Guo C (2022) Effect of fast-frequency pulsed waveforms on the microstructure and mechanical properties of Ti–6Al–4V alloy welded by FFP-TIG. J Mater Res Technol 20:516–531. https://doi.org/10.1016/j.jmrt.2022.07.126

Huang Y, Yang DQ, Wang KH, Wang L, Zhou Q (2020) Stability analysis of GMAW based on multi-scale entropy and genetic optimized support vector machine. Measurement 151:107282. https://doi.org/10.1016/j.measurement.2019.107282

Yao P, Zhou K, Zhu Q (2017) Quantitative evaluation method of arc sound spectrum based on sample entropy. Mech Syst Signal Pr 92:379–390. https://doi.org/10.1016/j.ymssp.2017.01.016

Nie J, Ma JR, Shi Y (2015) Correlation between stability of aluminium alloy pulsed metal-inert gas welding and pulse current signal. Mater Res Innov 19:674–678. https://doi.org/10.1179/1432891714Z.0000000001174

Liao HP, Zhang WX, Xie HM, Li XY, Zhang Q, Wu XM, Tian JY, Wang ZM (2023) Effects of welding speed on welding process stability, microstructure and mechanical performance of SUS304 welded by local dry underwater pulsed MIG. J Manuf Process 88:84–96. https://doi.org/10.1016/j.jmapro.2023.01.047

Planckaert JP, Djermoune E, Brie D, Briand F, Richard F (2010) Modeling of MIG/MAG welding with experimental validation using an active contour algorithm applied on high speed movies. Appl Math Model 34(4):1004–1020. https://doi.org/10.1016/j.apm.2009.07.011

Zhao D, Wang Y, Liang D, Ivanov M (2020) Performances of regression model and artificial neural network in monitoring welding quality based on power signal. J Mater Res Technol 9(2):1231–1240. https://doi.org/10.1016/j.jmrt.2019.11.050

Pincus SM(1991) Approximate entropy as a measure of system complexity. P Natl Acad Sci Usa 88:2297-301

Chen C, Sun GR, Du WB, Li Y, Fan CL, Zhang HJ (2022) Influence of heat input on the appearance, microstructure and microhardness of pulsed gas metal arc welded Al alloy weldment. J Mater Res Technol 21:121–130. https://doi.org/10.1016/j.jmrt.2022.09.028

Guo N, Fu YL, Xing X, Liu YK, Zhao SX, Feng JC (2018) Underwater local dry cavity laser welding of 304 stainless steel. J Mater Res Technol 260:146–155. https://doi.org/10.1016/j.jmatprotec.2018.05.025

Fu JW, Yang YS, Guo JJ, Ma JC, Tong WH (2008) Formation of a two-phase microstructure in Fe–Cr–Ni alloy during directional solidification. J Cryst Growth 311(1):132–136. https://doi.org/10.1016/j.jcrysgro.2008.10.021

Di XJ, Ji SX, Cheng FJ, Wang DP, Cao J (2015) Effect of cooling rate on microstructure, inclusions and mechanical properties of weld metal in simulated local dry underwater welding. Mater Design 88:505–513. https://doi.org/10.1016/j.matdes.2015.09.025

Vashishtha H, Taiwade RV, Sharma S (2017) Effect of electrodes and post weld solution annealing treatment on microstructures, mechanical properties and corrosion resistance of dissimilar high nitrogen austenitic and conventional austenitic stainless steel weldments. Mater Trans 58(2):182–185. https://doi.org/10.2320/matertrans.M2016175

Ramkumar KD, Abraham WS, Viyash V, Arivazhagan N, Rabel AM (2017) Investigations on the microstructure, tensile strength and high temperature corrosion behaviour of Inconel 625 and Inconel 718 dissimilar joints. J Manuf Process 25:306–322. https://doi.org/10.1016/j.jmapro.2016.12.018

Fan YH, Zhang B, Wang JQ, Han EH, Ke W (2019) Effect of grain refinement on the hydrogen embrittlement of 304 austenitic stainless steel. J Mater Sci Technol 35(10):2213–2219. https://doi.org/10.1016/j.jmst.2019.03.043

Acknowledgements

The authors are thankful to editors and reviewers.

Funding

This work was supported by the National Natural Science Foundation of China (grant number U2141216); Key Technical Projects of Shenzhen City (grant number JSGG20201201100401005, grant number JSGG20201201100400001); Marine Economic Development (Six Marine Industries) Special Funding Project of Guangdong Province (grant number GDNRC[2021]46); and Science and Technology Planning Project of Guangdong Province (grant number 2021B1515420006; grant number 2021B1515120026).

Author information

Authors and Affiliations

Contributions

The conceptualization and manuscript were conducted by Wenxu Zhang. The experiments were designed by Haipeng Liao and Bin Zhang; funding acquisition and manuscript review were performed by Qin Zhang, Xiangmiao Wu, Jiyu Tian, and Zhenmin Wang. All the authors took part in the paper.

Corresponding authors

Ethics declarations

Ethics approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Written informed consent for publication was obtained from all participants.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, W., Liao, H., Zhang, B. et al. Effect of backward median current on stability, microstructure, and mechanical properties of SUS304 weldments fabricated by local dry underwater MIG welding. Int J Adv Manuf Technol 128, 283–295 (2023). https://doi.org/10.1007/s00170-023-11896-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11896-y