Abstract

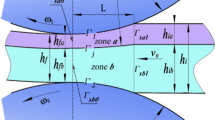

Composite strips combine the advantages of each component, and the thickness of each layer directly determines whether it can meet the special requirements of different environments and service conditions. Prediction of rolling force and layer thickness is very important for process control and product performance. There are many complex strong coupling variables in bimetal clad rolling (CR), and it is difficult to build a concise mathematical model suitable for production. The idea of equivalent clad rolling (ECR) is creatively proposed and the corresponding relationship between CR and ECR is established. By analyzing the deformation zone of each metal in the CR process, the equivalent roll radius and equivalent deformation length of each layer are established, the calculation methods of improved Stone and Bland-Ford-Hill rolling force applicable to the bimetal CR process are presented, the calculation connection bridge of equal rolling force is proposed, the coupling iteration relationships of flattening radius and rolling force are established through adjusting the reduction rate of each layer, and then the prediction model of layer thickness and rolling force in bimetal CR is developed. The ECR analytical model is verified by finite element simulation and related CR experiments. Using the proposed model, the relationships between the layer thicknesses before and after CR are established, and the effects of different process parameters such as reduction rate, inlet clad ratio, total inlet thickness, friction factor ratio on outlet clad ratio and the rolling force are expounded. Based on the mature single-strip rolling calculation model, the proposed ECR prediction model is short in calculation time and convenient in application.

Similar content being viewed by others

References

Wang J, Zhao F, Xie G, Hou Y, Wang R, Liu X (2021) Rolling deformation behaviour and interface evaluation of Cu-Al bimetallic composite plates fabricated by horizontal continuous composite casting. J Mater Process Tech 298:117296

Yang C, Huang B, Guo Y, Wang J (2021) Characterization of delamination effects on free vibration and impact response of composite plates resting on visco-Pasternak foundations. Int J Mech Sci 212:106833

Liu YM, Wang ZH, Wang T, Sun J, Zheng XG, Zhang DH, Huang QX (2022) Prediction and analysis of the force and shape parameters in variable gauge rolling. Chin J Mech Eng-En 35(4):79–92

Liao B, Zhou J, Ai S, Lin Y, Xi L, Cao Y, Xiao D (2021) Comparison of laminate thickness on the low velocity impact behaviors for Z-pinned composite laminates. Int J Mech Sci 204:106567

Zhou Q, Jia B, Guo B, Liu R, Zhu L, Bataev I, Chen P (2022) Microstructure and mechanical properties of the bonding interface of explosively welded TA2/Q235 composite under dynamic shear loading. Int J Mech Sci 225:107362

Yang YH, Jiang ZZ, Chen YT, Liu XF, Sun JH, Wang WJ (2022) Interfacial microstructure and strengthening mechanism of stainless steel/carbon steel laminated composite fabricated by liquid-solid bonding and hot rolling. Mater Charact 191:112122

He D, Xu H, Wang T, Liu J (2021) Nonlinear vibration of corrugated rolling mill based on dynamic rolling force. Iron Steel 56(6):75–81

Zhang L, Meng L, Zhou S, Yang F (2004) Behaviors of the interface and matrix for the Ag/Cu bimetallic laminates prepared by roll bonding and diffusion annealing. Mater Sci Eng A 371(1–2):65–71

Jiang Y, Tang H, Zhang X (2019) Rotation mechanics and numerical simulation of hot rolling process under asymmetric rolls. Int J Mech Sci 151:785–796

Hu Y, Sun J, Peng W, Zhang D (2021) Nash equilibrium-based distributed predictive control strategy for thickness and tension control on tandem cold rolling system. J Process Contr 97(2):92–102

Yang H, Li J, Sun T (1820) Niu W (2021) Automatic control system of hydraulic tension pilot warm rolling mill. J Phys Conf Ser 1:012171

Wang Y, Li C, Peng L, An R, Jin X (2021) Application of convolutional neural networks for prediction of strip flatness in tandem cold rolling process. J Manuf Process 68:512–522

Abdelkhalek S, Montmitonnet P, Legrand N, Buessler P (2011) Coupled approach for flatness prediction in cold rolling of thin strip. Int J Mech Sci 53(9):661–675

Wang X, Liu X, Wang S, Zhi Y (2018) Analysis and experiment on rolling of strips with various thicknesses in lateral direction. Int J Mech Sci 141:393–400

Chen S, Li W, Liu X (2014) Calculation of rolling pressure distribution and force based on improved Karman equation for hot strip mill. Int J Mech Sci 89:256–263

Pérez-Prado MT, Del Valle J, Ruano OA (2004) Effect of sheet thickness on the microstructural evolution of an Mg AZ61 alloy during large strain hot rolling. Scripta Mater 50(5):667–671

Farokhpey A, Parsa M (2022) Analyzing the accumulative roll bonding deformation zone behavior by FEM, upper bound, and experimental methods. J Manuf Process 81:328–345

Stone MD (1953) Rolling of thin strip. Iron Steel Eng 2:115–128

Bland D, Ford H (1948) The calculation of roll force and torque in cold strip rolling with tensions. Proc I Mech Eng 159(1):144–163

Wang JS, Jiang ZY, Tieu AK, Liu XH, Wang GD (2008) A flying gauge change model in tandem cold strip mill. J Mater Process Tech 204(1–3):152–161

Parvizi A, Afrouz F (2016) Slab analysis of asymmetrical clad sheet bonded before rolling process. Int J Adv Manuf Tech 87(1–4):137–150

Wang H, Zhang D, Zhao D (2015) Analysis of asymmetrical rolling of unbonded clad sheet by slab method considering vertical shear stress. ISIJ Int 55(5):1058–1066

Wang H, Li X, Sun J, Wang Z, Zhao D, Zhang D (2016) Analysis of sandwich rolling with two different thicknesses outer layers based on slab method. Int J Mech Sci 106:194–208

Alexandrov S, Lyamina E (2017) Extension of Orowan’s method to analysis of rolling of three-layer sheets. Proc Eng 207:1391–1396

Cawthorn C, Minton J, Brambley E (2016) Asymptotic analysis of cold sandwich rolling. Int J Mech Sci 106:184–193

Sun J, Liu Y, Hu Y, Wang Q, Zhang D, Zhao D (2016) Application of hyperbolic sine velocity field for the analysis of tandem cold rolling. Int J Mech Sci 108:166–173

Nalawade R, Puranik A, Balachandran G, Mahadik K, Balasubramanian V (2013) Simulation of hot rolling deformation at intermediate passes and its industrial validity. Int J Mech Sci 77:8–16

Haghighat H, Saadati P (2015) An upper bound analysis of rolling process of non-bonded sandwich sheets. Trans Nonferrous Met Soc China 25(5):1605–1613

Pan S, Huang M, Tzou GY, Syu S (2006) Analysis of asymmetrical cold and hot bond rolling of unbounded clad sheet under constant shear friction. J Mater Process Tech 177(1–3):114–120

Jeon C, Han S, Joo B, Van Tyne C, Moon YH (2013) Deformation analysis for cold rolling of Al-Cu double layered sheet by physical modeling and finite element method. Met Mater-Int 19(5):1069–1076

Wang CY, Jiang YB, Xie JX, Mao XD, Zhou DJ, Zhang XJ (2017) Thickness variation of aluminum layer-steel layer of embedded aluminum-steel composite strip during cold roll bonding. Trans Nonferrous Met Soc China 27(4):766–775

Sun JL, Peng Y, Liu HM (2014) Dynamic characteristics of cold rolling mill and strip based on flatness and thickness control in rolling process. J Cent South Univ 21(2):567–576

Huang Y, Zhou X, Gao Z (2022) Thickness prediction of thin strip cold rolling based on VBGM-RBF. Int J Adv Manuf Tech 120(9):5865–5884

Li J, Wang X, Yang Q et al (2022) Rolling force prediction in cold rolling process based on combined method of T-S fuzzy neural network and analytical model. Int J Adv Manuf Technol 121:4087–4098. https://doi.org/10.1007/s00170-022-09567-5

Jiang ZY, Zhu HT, Tieu AK (2003) Effect of rolling parameters on cold rolling of thin strip during work roll edge contact. J Mater Process Tech 140(1–3):535–541

Funding

This study is financially supported by the National Natural Science Foundation of China (Nos.: 51904206, 51905372, 52105390, 52205404), National Key R&D Program of China (Nos.: 2018YFB1308700, 2021YFB3401000), Fundamental Research Program of Shanxi Province (No.: 202203021212293), Shanxi Province Science and Technology Major Projects (Grant No. 20181102015, 20181101008), and Central Government Guides the Special Fund Projects of Local Scientific and Technological Development (YDZX20191400002149).

Author information

Authors and Affiliations

Contributions

Pingju Hao: writing—original draft, formula derivation. Yuanming Liu: formal analysis, writing—review and editing. Yanxiao Liu: data measurement, writing—review. Zhenhua Wang: visualization, validation. Tao Wang: conceptualization, methodology, writing—review and editing. Qingxue Huang: conceptualization, methodology, project administration. Zhenguo Wang: methodology, validation.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hao, P., Liu, Y., Liu, Y. et al. Analysis of rolling force and layer thickness in bimetal clad rolling. Int J Adv Manuf Technol 127, 4401–4411 (2023). https://doi.org/10.1007/s00170-023-11818-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11818-y