Abstract

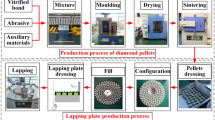

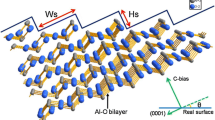

Sapphire single crystal has great potential applications in the semiconductor field. Due to its brittle characteristics. Crack failure on ultra-thin sapphire surface were prone to happen using tradition paraffin bonding clamping method during double-side processing, which severely restricted its processing efficiency. Thus, for overcoming the problem, the layer stacked clamping (LSC) method was proposed by using van der Waals forces and capillary forces that caused by dropping a liquid between workpiece and baseplate. A series of experiments were conducted for studying the characteristic of layer stacked clamping (LSC) method on polishing ultrathin sapphire wafer with double-side polishing machine. A self-made friction force test platform was built for learning the friction force between sapphire wafer and baseplate with different baseplate (stainless steel, cast iron, and aluminum alloy) and different baseplate surface roughness (Ra 3.6 nm, 68.2 nm, 210.1 nm, and 517.9 nm). Single-factor polishing experiments were carried out on baseplate with different flatness (PV value 5.3 μm, 9.8 μm, 19.9 μm, and 29.7 μm) and different thicknesses (0.082 mm, 0.104 mm, and 0.119 mm). The double-side polishing experiments were carried out to compare the polishing performance on the ultrathin sapphire polishing between LSC method and traditional paraffin bonding method. The results show that the friction forces of stainless steel and iron increase under the adsorption of droplets. Stainless steel performs higher friction force and is more suitable for making the baseplate. The inner fringe of limiter was cut off by the edge of the sapphire wafer, and a slope was thereby formed. According to polishing results, the LSC method has a higher efficiency on the clamping wafers than traditional paraffin bonding method. The surface roughness, flatness, and material removal rates are better than paraffin bonding. Finally, a smooth surface with a surface roughness (Sa) of 1.1 nm and flatness (PV) of 0.988 μm was obtained by the LSC method, significantly improving the clamping and processing efficiency of ultra-thin sapphire.

Similar content being viewed by others

References

Gentilman R, Maguire E, Starrett H, Hartnett T, Kirchner H (1981) Strength and transmittance of sapphire and strengthened sapphire. J Am Ceram Soc 64(9):C-116-C-127

Chan P, Rienzi V, Lim N, Chang H-M, Gordon M, DenBaars SP, Nakamura S (2021) Demonstration of relaxed InGaN-based red LEDs grown with high active region temperature. Appl Phys Express 14(10):101002

Lobo-Ploch N, Mehnke F, Sulmoni L, Cho HK, Guttmann M, Glaab J, Hilbrich K, Wernicke T, Einfeldt S, Kneissl M (2020) Milliwatt power 233 nm AlGaN-based deep UV-LEDs on sapphire substrates. Appl Phys Lett 117(11):111102

Ooi YK, Zhang J (2018) Light extraction efficiency analysis of flip-chip ultraviolet light-emitting diodes with patterned sapphire substrate. IEEE Photon J 10(4):1–13

Abromavičius G (2020) Microstructural and optical properties of metal oxide optical coatings deposited by ion beam sputtering and their application in UV spectral range Dissertation. Vilniaus Universitetas

Shih AJ, Denkena B, Grove T, Curry D, Hocheng H, Tsai H-Y, Ohmori H, Katahira K, Pei Z (2018) Fixed abrasive machining of non-metallic materials. CIRP Ann 67(2):767–790

Gao T, Li C, Zhang Y, Yang M, Jia D, Jin T, Hou Y, Li R (2019) Dispersing mechanism and tribological performance of vegetable oil-based CNT nanofluids with different surfactants. Tribol Int 131:51–63

Wang Y, Li C, Zhang Y, Li B, Yang M, Zhang X, Guo S, Liu G, Zhai M (2017) Comparative evaluation of the lubricating properties of vegetable-oil-based nanofluids between frictional test and grinding experiment. J Manuf Process 26:94–104

Wang X, Li C, Zhang Y, Ali HM, Sharma S, Li R, Yang M, Said Z, Liu X (2022) Tribology of enhanced turning using biolubricants: a comparative assessment. Tribol Int 107766

Kasai T (2008) A kinematic analysis of disk motion in a double sided polisher for chemical mechanical planarization (CMP). Tribol Int 41(2):111–118

Kim H-M, Manivannan R, Moon D-J, Xiong H, Park J-G (2013) Evaluation of double sided lapping using a fixed abrasive pad for sapphire substrates. Wear 302(1-2):1340–1344

Wang L, Hu Z, Fang C, Yu Y, Xu X (2018) Study on the double-sided grinding of sapphire substrates with the trajectory method. Precis Eng 51:308–318

Li Z, Deng Z, Ge J, Liu T, Wan L (2022) Experimental and theoretical analysis of single-sided and double-sided chemical mechanical polishing of sapphire wafers. Int J Adv Manuf Technol 119(7):5095–5106

Li Z, Deng Z, Hu Y (2020) Effects of polishing parameters on surface quality in sapphire double-sided CMP. Ceram Int 46(9):13356–13364

Wang L, Hu Z, Yu Y, Xu X (2018) Evaluation of double-sided planetary grinding using diamond wheels for sapphire substrates. Crystals 8(7):262

Xu L, Chen H, Lyu B, Hang W, Yuan J (2022) Study on rheological properties and polishing performance of viscoelastic material for dilatancy pad. Precis Eng 77:328–339

Pan B, Kang R, Guo J, Fu H, Du D, Kong J (2019) Precision fabrication of thin copper substrate by double-sided lapping and chemical mechanical polishing. J Manuf Process 44:47–54

Zhou H, Xu XM, Zhuo ZG, Zang Y, Xu RX, Feng H (2012) In Study on improved grinding process of sapphire with LED substrate material in manufacturing engineering, Advanced Materials Research. Trans Tech Publ, pp 314–317

Xu L, Wang L, Chen H, Wang X, Chen F, Lyu B, Hang W, Zhao W, Yuan J (2022) Effects of pH values and H2O2 concentrations on the chemical enhanced shear dilatancy polishing of tungsten. Micromachines 13(5):762

Li Z, Pei Z, Funkenbusch P (2011) Machining processes for sapphire wafers: a literature review. Proc Inst Mech Eng B J Eng Manuf 225(7):975–989

Price GL, Usher BF (1991) In Application of epitaxial lift-off to optoelectronic material studies, Physical Concepts of Materials for Novel Optoelectronic Device Applications I: Materials Growth and Characterization. SPIE, pp 543–550

Li M, Karpuschewski B, Ohmori H, Riemer O, Wang Y, Dong T (2021) Adaptive shearing-gradient thickening polishing (AS-GTP) and subsurface damage inhibition. Int J Mach Tools Manuf 160:103651

Li M, Karpuschewski B, Riemer O (2022) Controllable shearing chain-thickening polishing process for machining of barium borate. CIRP J Manuf Sci Technol 37:291–301

Li M, Liu MH, Riemer O, Song FZ, Lyu BH (2021) Anhydrous based shear-thickening polishing of KDP crystal. Chin J Aeronaut 34(6):90–99

Li M, Karpuschewski B, Riemer O (2021) High-efficiency nano polishing of steel materials. Nanotechnol Rev 10(1):1329–1338

Ovchinnikov V (1991) The deformation mechanisms of the porous structure of a poly (ethylene terephthalate) nuclear track membrane. J Membr Sci 64(3):237–246

Li M, Liu M, Riemer O, Karpuschewski B, Tang C (2021) Origin of material removal mechanism in shear thickening-chemical polishing. Int J Mach Tools Manuf 170:103800

Li M, Song F, Huang Z (2022) Control strategy of machining efficiency and accuracy in weak-chemical-coordinated-thickening polishing (WCCTP) process on spherical curved 9Cr18 components. J Manuf Process 74:266–282

Li M, Xie J (2022) Green-chemical-jump-thickening polishing for silicon carbide. Ceram Int 48(1):1107–1124

Chen ZX, Cao LL, Yuan JL, Lyu BH, Hang W, Wang JH (2020) The mechanism of layer stacked clamping (LSC) for polishing ultra-thin sapphire wafer. Micromachines 11(8):759

Hiep NH, Thanh MD, Huy ND (2018) Viscous–capillary traveling waves associated with classical and nonclassical shocks in van der Waals fluids. Nonlinear Anal: Real World Appl 41:107–127

Funding

This research was funded by Basic Research Project of Wenzhou City, China (Grant Nos. G20210002 and G20210001), Natural Science Foundation of Zhejiang Province, China (Grant Nos. LQ22E050008 and LQ23E050003), and National Natural Science Foundation of China (Grant Nos. U20A20293, 52275467, and 51905485).

Author information

Authors and Affiliations

Contributions

The corresponding author Ming Feng has guided the paper writing and contributed to data discussion and article revision. Zhixiang Chen was responsible for writing, developing the experimental designs and measurements, taking part in ensuring the experimental environment and preparing workpieces, and analyzing experimental results. Shunkai Han assisted in data processing and paper revision. Hongyu Chen and Xianglei Zhang were responsible for simulating the cutting trace of abrasive grain and improving the test jigs.

Corresponding author

Ethics declarations

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent for publication

Not applicable.

Conflict of interest

The authors declare no competing interests.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Chen, Z., Han, S., Feng, M. et al. Performance assessment of ultrathin sapphire wafer polishing with layer stacked clamping (LSC) method. Int J Adv Manuf Technol 127, 3761–3771 (2023). https://doi.org/10.1007/s00170-023-11781-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00170-023-11781-8